Top 5 Videos: 3D Printing Concrete Simulator

Hello and welcome back to another top 5 videos of the week, where we’ve been burning the midnight oil in an effort to bring you the latest and greatest, most interesting and unique, and sometimes just unexplainable, you-just-have-to-watch-it content there is to find in the wide world of 3D printing. This week, we take a look at the customer side of additive manufacturing, learn about the fine work that goes into micro designs, take a simulation of a 3D printed concrete process, prepare for the holidays with some 3D printed help around the house, and learn a new hobby courtesy of Gary Willett and 3D printing. So without further ado, let’s go take a look!

Top 1: The Voice of the Customer, by Prodways Group

In this video, we listen in to a recent interview with Prodways client Frederic Rapp, CEO of Crown Ceram. Their discussion highlights the evolution of 3D printing as a new and rapidly evolving technology. Rapp emphasizes the significance of partnering with industry leaders like Prodways, praising their support and responsiveness to specific business needs. Prodways’ attentive approach aids in identifying necessary machine functionalities and suitable materials, especially crucial in high-volume 3D printing, particularly within the dental field. Mr. Rapp appreciates not only the technology but also highlights the value of the people behind Prodways, emphasizing the team’s excellence and support. Not just a glowing review, but an excellent look at the industry from the inside – from a client who utilizes additive manufacturing daily. Listen to the whole interview below.

Top 2: Diving Into the Little Details with BMF

In this video, John Kawola, CEO of Boston Micro Fabrication, highlights the growing trend of miniaturization in various industries. He highlights the growing demand for high-resolution additive manufacturing for small, precise components crucial in medical devices, electronics, optics, life sciences, and more. As products become smaller, conventional manufacturing methods become costlier, making 3D printing an increasingly viable solution, especially for intricate, custom parts. Boston Micro Fabrication’s global presence aids in meeting diverse customer needs. They explore unique applications like thin cosmetic veneers and life science platforms, aiming to revolutionize drug development and cosmetics testing. Learn more about Boston Micro Fabrications and the big world of small components by watching the full video!

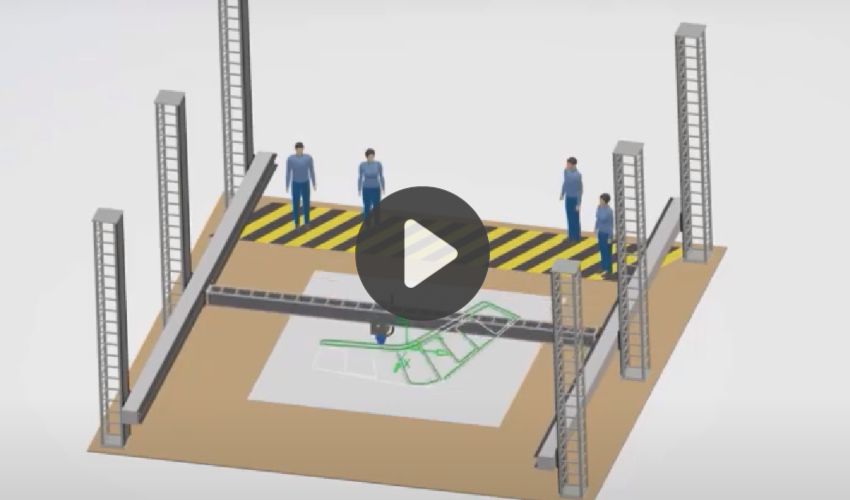

Top 3: A 3D Printed Concrete Interlude

In this video by 3DS Delmia, we take a step back and enjoy an instrumental journey through the creation process of a 3D printed concrete structure. In this computer simulation, we are given an in-depth look at the various components and steps that are taken when constructing objects with 3D printing. With concrete 3D printing becoming increasingly popular in the construction sector around the world, this visual aid provides an interesting slice into current technologies and practices which may one day become as commonplace as the action of building a wall with brick and mortar. Take a look at the video below to see the construction firsthand, and don’t forget to check out our infographic on 3D printing in the construction industry, to continue learning more!

Top 4: Practical Home 3D Printing for the Holidays

In this video from Functional Print Friday, He addresses the need to protect outdoor outlets for Christmas lights; especially when using a smart plug system and facing challenges due to weather exposure. FPF introduces a plug cover design using 3D printing, discussing the measurements, material choice (PLA), and considerations for printing without supports. The design resembles a shelter with a gutter-like feature, to protect the outlet from water, wind, and snow. After printing and installation, they test the cover using a homemade rain simulator. The video concludes with useful observations and analysis of the print’s success, and monitoring how the PLA material holds up against outdoor elements. The STL files for the cover are made available on their website for free. So if you’ve already got lights up at home, consider checking out this video and printing your own today!

Top 5: Building 3D Printed Animatronics with Gary Willett

In our final video, we join Gary Willett Animatronics as he expresses gratitude for reaching 500 subscribers – though, by the time of posting this, he is up to 1.4k! Congrats, Gary! What we get is a journey into a 3D printed animatronic project highlighting his creativity, ingenuity, and undoubtedly perseverance as well. He aims to offer STL files via Patreon, enabling viewers to create animatronics by providing instructions for servo selection and hardware. He emphasizes the joy of animating creations and showcases his work on Instagram. Throughout the video, Gary discusses his design process, testing movements with servos, and their capabilities. He delves into the complexities of movement creation, emphasizing the importance of torque and metal gears in servos. He aims for detailed, realistic movements in small-scale animatronics. Worth a look for such an in-depth and passionate project! Join the Gary following today and get started on your own 3D printed animatronics!

Which was your favorite video? Let us know in a comment below or on our Linkedin, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover photo credits: 3DS Delmia