#3DStartup: Craft Health Is Personalizing Medicines With 3D Printing

According to a report from the International Federation of Pharmaceutical Manufacturers and Associations (IFPMA), in 2022 combined “direct, indirect and induced effects” of the global biopharmaceutical industry led to a contribution of $1.838 trillion to the world’s GDP with spending on R&D playing a particularly important role. Indeed, annual spending on research for the industry is 8.1 times greater than that of the aerospace and defense industry. This shows that it is a constantly evolving industry, in which innovation is a key driver. And one of the factors driving this innovation is additive manufacturing. As you know, 3D technologies have long been used in the medical sector, and the pharmaceutical industry also benefits from their advantages. In fact, they are increasingly used to design tailor-made medicines that better meet patients’ needs. Additive manufacturing also makes it possible to combine several treatments in a single tablet, making it considerably easier to take medication. Among the players who have made this reality their specialty is Singapore-based start-up Craft Health. It has developed a 3D printing solution to produce personalized medicines and more controlled pharmaceutical products. We caught up with one of its founders to find out more!

3DN: Could you introduce yourself and your connection to 3D printing? How did Craft Health come about?

My name is Wei Jiang GOH, and I am a pharmacist by training and practiced as a pharmacist in a Singapore hospital. Subsequently, I was awarded the PhD-MBA double degree scholarship at the National University of Singapore (NUS) where I uncovered my passion for the convergence between technology and commercialization. In my final year of my PhD, I spoke to my now co-founder, Dr. Seng Han LIM, on working together to solve a problem that resonates with both of us. Our backgrounds were largely similar as we were both practicing pharmacists in a hospital setting before.

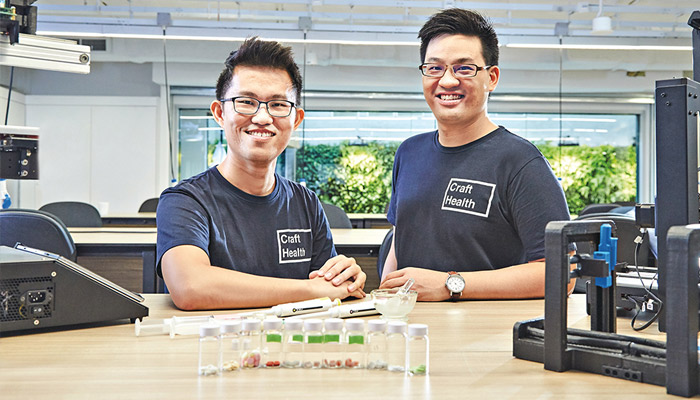

Dr. Lim Seng Han (left) and Dr. Wei Jiang Goh (right), the co-founders of Craft Health

We thought that polypharmacy, or having too many medicines, was a big issue. Especially since we saw patients going home with bags full of pills on a daily basis when we were pharmacists. Polypharmacy is typically associated with poor patient outcomes, especially since patients become confused from taking some many different pills, or suffer from pill taking fatigue. We brainstormed for different solutions, and eventually realized what my co-founder, Dr Lim, was working on for his PhD thesis could be the solution.

He was working on 3D printing to personalize medicines. We realized we could use 3D printing as well as our formulation skills to 3D print and combine multiple medicines into just one polypill. This would effectively reduce the pill burden and solve the problem of polypharmacy. We obtained a small grant, tested out the technology, and Craft Health was started in 2019 in Singapore.

3DN: How are Craft Health products manufactured?

Craft Health™ helps various stakeholders in the nutraceutical and pharmaceutical industries such as hospitals, clinics, compounding pharmacies, pharmaceutical and supplement companies solve various pain points through our Craft Health™ 3D printing platform.

These pain points include new product development, using 3D printing as a rapid prototyping tool, combining multiple medicines or supplements into a single polypill, customizing the form (shape, geometry, colour, taste) of tablets, achieving specific customized active ingredient release profiles and just-in-time manufacture.

The Craft Health™ 3D printing platform consists of 3 key elements:

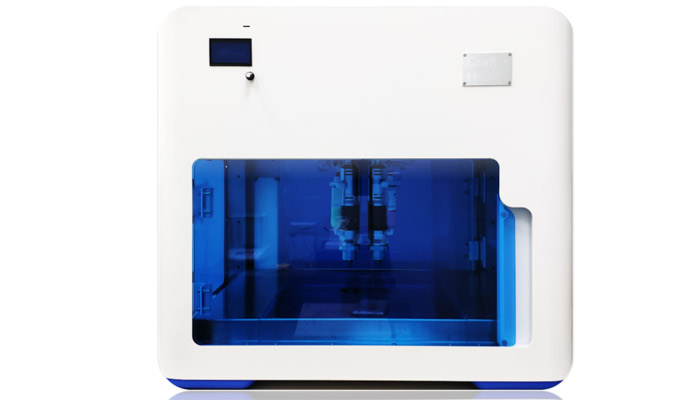

- CraftMake: The 3D printer. This represents one of the world’s first 3D printer for pharmaceuticals and nutraceuticals, using a heat and UV-free technique.

- CraftControl: The 3D printing software. We have input several printing parameters suitable for 3D printing of pills / tablets.

- CraftBlends: Our proprietary mix of non-active ingredients, sourced from the United States Food & Drug Administration (USFDA) Generally Regarded As Safe (GRAS) list. This proprietary mix allows a 3D printable paste to be made, with a specific controlled release profile, such as immediate/delayed/sustained release.

Together, these 3 elements are optimized for each other, in order to 3D print nutraceuticals and pharmaceuticals in a precise and controlled manner, with relatively high throughput. Our core capabilities include formulation development, 3D printing and pilot scale production in a Class 10K cleanroom environment.

CraftMake makes it possible to produce drugs without the use of heat or UV rays

3DN: What are the main advantages of additive manufacturing in the pharmaceutical industry?

The benefits of 3D printing for this market are numerous. Firstly, there’s the mass customization of medicines, in regard to dose, selection of medicines and even release profile (immediate, sustained or delayed release of the medicine). Secondly, 3D technologies can be used to modify the taste profile or mask the taste of unpleasant-tasting drugs. They can also design complex shapes or geometries for specific controlled release profiles or targeting.

What’s more, 3D printing is able to combat the issues of polypharmacy by combining several drugs in a single tablet. Finally, thanks to additive manufacturing, it is possible to produce small series for testing purposes, in quantities that are not necessarily profitable for factories or manufacturing processes.

3DN : What are Craft Health’s future projects?

We are focusing on two key vertical markets for Craft Health. Firstly, we have developed a Colon targeting Drug Delivery System (DDS) using our Craft Health 3D Printing Platform. Through the combination of geometric design and materials, we are able to target the large intestine, an often-neglected site. We will be working with different groups to develop a pipeline of therapeutics utilizing our DDS for colorectal cancer and inflammatory bowel disease.

Examples of 3D printed medicines

Secondly, we are expanding into the compounding pharmacy scene. Our range of 3D printers, CraftMake can 3D print pharmaceutical and nutraceutical preparations consistently in a continuous manner, providing compounding pharmacies with potentially reduced cost of manpower and increased production output.

Lastly, we will also be working with a Singapore hospital to launch Southeast Asia’s very first clinical trial involving 3D printing medicines. The first use case will be a polypill for tuberculosis, where it is pertinent to adhere to the prescribed medication regimen, as it is highly contagious.

3DN: Any last words for our readers?

Watch out for this space next year as we continue to innovate at the forefront of 3D printed medicines! You can find out more on our website HERE.

What do you think of Craft Health and its 3D printed medicines? Let us know in a comment below or on our Linkedin, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: Craft Health