Researchers Unveil Breakthrough 3D Bioprinting Method Using Plant Cells

3D printing has proven to be a versatile technology, expanding its applications across various fields, from manufacturing to medicine. It has become an indispensable tool in many sectors due to its ability to customize products and create complex, unique structures from a wide range of materials. Researchers worldwide have leveraged these benefits to develop innovative methods like bioprinting, which are transforming their respective fields. Recently, a team of researchers published a paper in the American Chemical Society, unveiling a new bioprinting method using inks containing genetically modified plant cells to produce living materials.

Until recently, developing living materials from plant cells was hampered by the simplicity of their structures, which limited their functionality. While researchers had already created living materials from bacterial and fungal cells, their ambitions extended further. The study we discuss today marks a breakthrough in overcoming these limitations. Led by scientists Ziyi Yu and Zhengao Di, the team developed Engineered Plant Living Materials containing modified plant cells with customizable behaviors and capabilities. This advancement has been made possible through the facilitation of 3D printing technology.

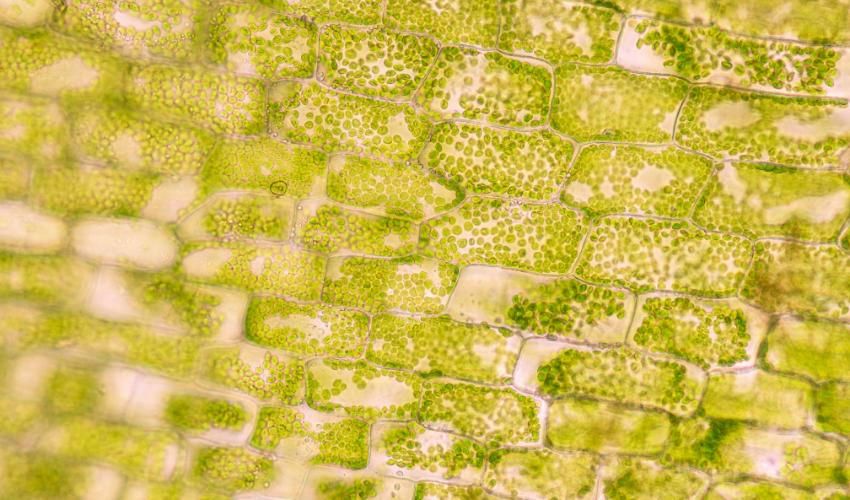

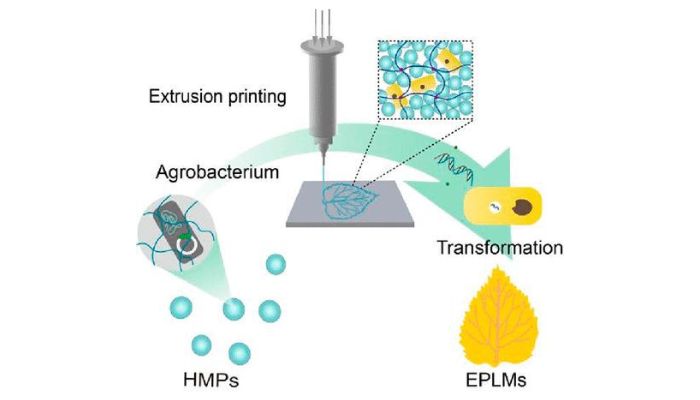

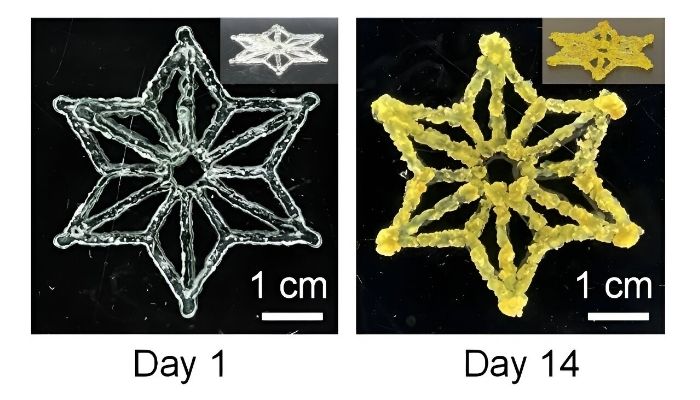

To achieve this, the researchers developed a bioink containing plant cells and bacteria. Specifically, the ink was composed of tobacco plant cells, gelatin, and hydrogel microparticles, which contained Agrobacterium tumefaciens, a bacterium that facilitates the transfer of DNA segments to plant genomes. This bioink was used to 3D print various shapes, such as grids, snowflakes, leaves, and spirals, for analysis. The printing was done using a three-axis 3D bioprinter with extrusion technology, and the shapes were cured with blue light to strengthen their structure. After 48 hours, the bacteria in the engineered living materials had transferred DNA to the growing tobacco cells. For example, a leaf-shaped print showed colors produced by the modified plant cells after just 24 hours. The researchers also observed that the plant cells continued to grow and replicate within the living materials over a few weeks, producing proteins as directed by the transferred DNA.

The study confirms the theory: the transferred DNA enabled the tobacco plant cells to produce green fluorescent proteins and plant pigments, which are valued as natural dyes and dietary supplements. By 3D printing this engineered living material, the researchers demonstrated their technique’s ability to create complex structures, control the measurements and growth of the prints, and manage their functions. According to the team, the combination of the characteristics of living organisms with the stability and durability of non-living substances (hydrogel) reveals great potential for creating pharmaceutical proteins and applying this engineered living material in sustainable construction.

This new method, which combines techniques from biology and engineering, pushes the boundaries of materials science. In their conclusion, the researchers stated, “By utilizing tobacco BY-2 cells in combination with biocompatible HMPs, this study demonstrates the remarkable potential of 3D bioprinting technologies in creating biocompatible, structurally diverse, and functionally dynamic EPLMs. […] These advancements signify a major step forward in the development of self-sustaining, responsive, and customizable living materials, with wide-ranging applications from sustainable construction to advanced biomanufacturing, opening up new possibilities for future technological and environmental solutions.” To learn more about this project, click here.

What do you think of this research released by the American Chemical Society? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here for the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: American Chemical Society