Cytosurge, 3D metal printing on a microscale

Direct 3D printing of metals with submicron resolution is a promising additive manufacturing technique for a wide range of sectors. The FluidFM µ3Dprinter from Cytosurge is the world’s first 3D printer capable of delivering such resolution in direct metal printing, while at the same time offering scalability and excellent prospects in both production costs and speed. Cytosurge AG has a new business unit for 3D printing at ETH Zurich and is leading the way with their FluidFM µ3Dprinter. To find out more about Cytosurge and their FludiFM technology, we met with Cytosurge’s Business Developer, Edgar Hepp.

3DN: Could you tell us a little bit more about Cytosurge?

Cytosurge was founded some years ago as a high-tech spin-off company from the ETH Zurich, a university that specializes in science, technology, engineering and mathematics. Our team is a passionate group of specialists with training in various disciplines such as business, engineering, biology and computer science; we have developed and commercialized the FluidFM technology. This technology enables an immense range of applications from science and biology to physics. At Cytosurge, we strive to provide tools for new possibilities and applications at the forefront of nanotechnology, particularly in medicine, life sciences and material science.

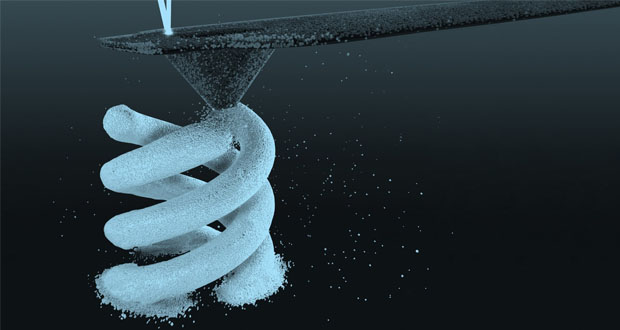

The FluidFM µ3Dprinter is a brand new development that builds on the FluidFM core technology, but ventures into a completely different application space that is namely that of printing metals on a micrometer scale.

3DN: How does the FluidFM 3D technology work?

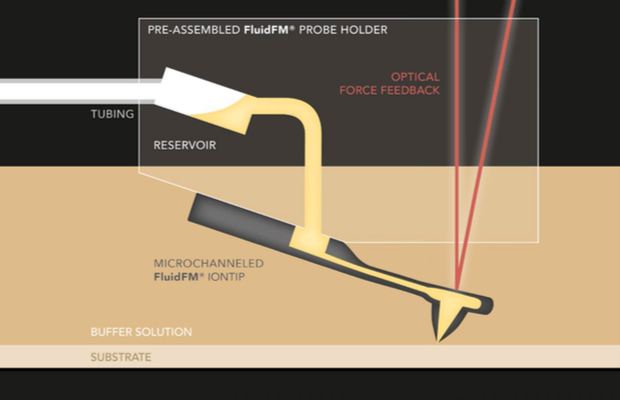

The FluidFm µ3Dprinter uses a combination of fluidic scanning probe microscopy and 3D printing. Using force sensitive pipettes that are called FluidFM iontips, they use closed microscopic channels to accurately dispense femtoliters of liquid into a 3D space.

In figure 1, you can see the micropipette that distributes the liquid which includes metal ions. The ions will then quickly deposit as a solid atom, thanks to an electrolytic process.

The FluidFM iontips have an aperture size at a few hundreds of a nanometer, about 200 times smaller than the diameter of a hair. This reduced size allows flow rates as small as femtoliters per second; a million times less than what the best sensitive flow sensors can detect.

With a laser beam, we monitor the motion of the cantilevered micropipette, which can be triggered by piconewtons of force, as can be seen in figure 2. With this kind of sensitivity, the force feedback can be monitored in the 3D printing process in situ

Currently, thanks to FluidFM µ3Dprinter, different metals can be printed such as copper, silver and gold.

3DN: What makes your product special?

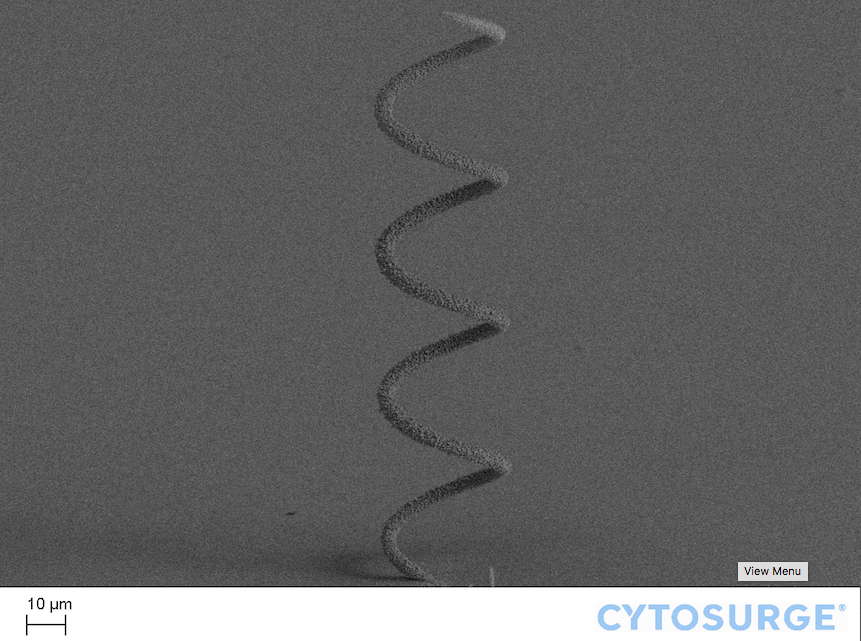

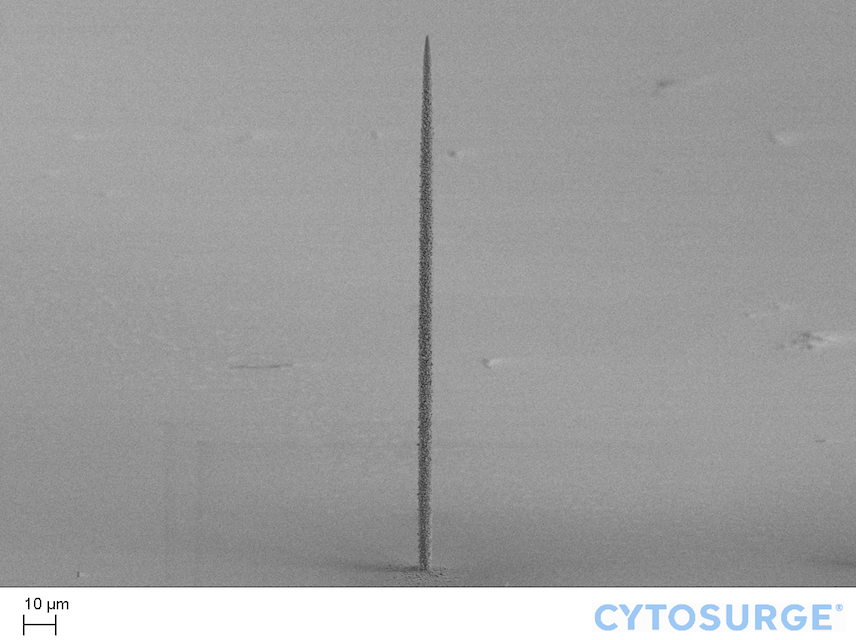

The FluidFM technology opens the door to a new world of metal object manufacturing, enabling new research opportunities in fields such as: microelectronics, semiconductors, surface modification, microbots, sensors, material science and many other fields. With a simple and intuitive operating interface, as well as our combination of functional instrument designs (as seen in figure 3), the FluidFM technology ensures that it is easy to use and ready for any application. The FluidFM µ3Dprinter enables the direct printing of complex 3D metal objects on a micrometer scale. By printing using a voxel-based process, virtually any design can be offered to the system, including overhanging structures with 90° angles. The µ3Dprinter’s high-precision surface and modification processes can also be used to print ultra-thin or structured objects by depositing various metals on your target surface.

Figure 3: The FluidFM µ3Dprinter and its controller. The printer is driven by intuitively operated software.

3DN: What do you see as the future for 3D metal printing?

We see a continuous effort to miniaturize components, customize mass production and reduce development and production cycles to provide a favorable environment for our 3D micro-printing technology. With our new technology, our printer can offer a multitude of possibilities that range from the printing of custom designs and rapid prototyping to mass production and volume production. Our newly developed micro metal 3D printing technology came at the perfect time, as we are currently in an accelerated technology driven marketplace where the right tools are essential to continue moving forward.

3DN: What are Cytosurge’s future plans?

Our FluidFM printer allows you to print the smallest objects directly out of a solution without the need of a template with a free printing process, and does not require post treatment or curing. As I stated previously, the FluidFM µ3Dprinter can already print copper, silver or gold. For the future, we are currently investigating the possibilities of printing with aqua ions Cd, Cr, Fe, In, Zn and Pt.

There is no other technology that is printing metal in a more direct way!

3DN: Any last words for our readers?

The FluidFM µ3Dprinter provides you with an entrance into this new field of technology and the scalability of the process. Through our machines’ excellent prospects in both production costs and speed, it will enable entirely new application fields to open. It is therefore important to keep an eye on this technology to see what other great things we create by following us on twitter and LinkedIn!

For more information about Cytosurge and their FluidFM technology, check out their website here.

Do you think that Cytosurge will revolutionize the manufacturing of microscopic metal parts? Share your opinion below in a comment or on our Facebook and Twitter page!