NTU’s Likelike 3D Printed Hearts Transform Surgeon Training

3D printing has made a remarkable impact in the medical field. From the training of future doctors to new and improved medical techniques, this technology has proved to be an increasingly valuable tool. Recently, a team of researchers at Nottingham Trent University (NTU) in the UK designed an artificial heart to train doctors in transplant surgery. This 3D printed model, crafted from materials like silicone and tissue, faithfully replicates the behavior of a natural human heart, mimicking its pulsation and blood flow. The aim of this research is to enable surgeons to familiarize themselves directly with the technical aspects of this type of surgery, in order to improve transplant results.

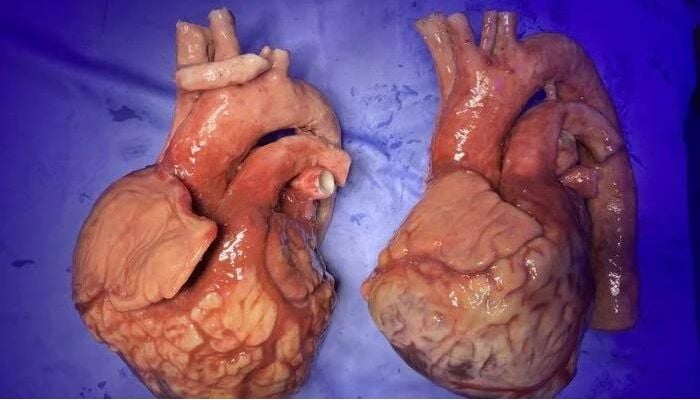

In general, surgeons typically train using cadavers or animal specimens, but these options have limitations in providing realistic training scenarios. Recognizing this challenge, researchers at Nottingham Trent University turned to 3D printing as a solution for creating lifelike surgical training models. Spearheaded by Richard Arm, a former film visual effects artist, the project focuses on developing 3D organ models that accurately replicate the behavior of real organs. Arm’s latest creation, a heart model, stands out as the closest match to the intricate characteristics of the human heart yet achieved.

How Are 3D Printed Hearts Made?

The heart models are specially designed to take account of patients’ specific conditions. In other words, these artificial organs reproduce patients’ pathological conditions to help doctors in their treatment. By simulating bleeding during incisions, these models recreate real-world scenarios, allowing practitioners to refine their skills and practice techniques for controlling bleeding effectively. Moreover, these models feature realistic tactile characteristics thanks to texture variations that reflect the diversity of heart tissue.

Data is gathered through cardiac scintigraphy, a precise medical imaging method offering detailed insights into the heart’s arteries. This data serves as the foundation for creating 3D models meticulously replicating the anatomical intricacies of the heart. Speaking on this process, Richard Arm explains, “Through extensive research, I eventually figured it out [how to turn patient’s scan data into a 3D-printed organ replica that looks and feels like a real human organ.] Now, I use medical scan data, 3D printers and traditional skills to make biological imitations of human anatomy that look and feel real enough to practice surgery on.” Not only has he created a lifelike heart model, but he’s also engineered a lung model that mimics natural breathing patterns. What’s truly remarkable about these creations is their reusability. Once restored to their original state, they can be used repeatedly, making them not only practical but also cost-effective, enabling more surgeons to be competently trained.

The Future of Research and Surgeon Training

The FHLTA (Freeman Heart and Lung Transplant Association) in the UK has been funding this project for some time. Last week, it was presented at the annual meeting of the Society for Cardiothoracic Surgery. The aim is to develop and manufacture these artificial organs to help more doctors in their practice. Explaining the benefits of this breakthrough, Richard Arm stated, “Through the commercialization of my work, air ambulance crews, first responders, trauma teams, medical schools, and military field surgical teams are now able to train for emergency surgery using the models I have developed. Surgeons can plan surgeries, as well as rehearse and teach procedures safely, reducing the risk of complications and even death.” To learn more about this project, click here.

What do you think of these lifelike 3D printed hearts for surgeon training? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: Nottingham Trent University