Better Rotator Cuff Treatment Thanks to 3D Printing

It is no secret that tendon injuries are some of the most painful and difficult to heal. Even minor ones can result in up to 12 weeks of recovery. But for the most severe, for example rotator cuff injuries, treatment is challenging and even in ideal situations take at least 6 months to recover. This is where a team of researchers at The Chinese University of Hong Kong (CUHK)’s Faculty of Medicine (CU Medicine) has come in. Knowing that more tailored and effective rotator cuff treatment was necessary, they have developed a new 3D-printable bioactive material for the repair of severe tears of the shoulder tendons.

The rotator cuff is the sheaf of tendons and ligaments that supports the arm at the shoulder joint. When torn, the injury is incredibly painful, preventing the performance of basic tasks involving arms or even sleeping, and requires surgery in almost all cases. Furthermore, with rotator cuff injuries expected to rise in the coming years due to aging populations in many countries, and with statistics showing that already at least 22% of the adult population has had one full-thickness rotator cuff tear, it has become critical to find more agile and effective solutions for treatment. This 3D-printable bioactive material could be the solution.

The team developing the materials including (starting from the left) Mr. Wang Chen-yang, Professor Elmer Ker, Dr. Zhang Xu and Dr. Li Ke (photo credits: CUHK)

Using a 3D-Printable Bioactive Material to Repair Rotator Cuffs

The key for the team at CUHK was in a polythiourethane elastomer, or PHT polymer, that when implemented in the body, could replace the torn tendons. Created using “click chemistry,” or chemical synthesis to join two molecular entities of choice, known for its ability to create almost exact copies of natural molecules, the material is able to mimic natural tendon. Indeed, testing has shown that in addition to its highly robust mechanical properties, the material can be stretched at least 10,000 times without failing.

The use of 3D printing as well is no accident. The team at CUHK chose to make a 3D-printable material as it will allow for greater personalization in treatment. Furthermore, the team believes that using 3D printing for rotator cuff treatment is more economical due to the possibility for on-demand fabrication.

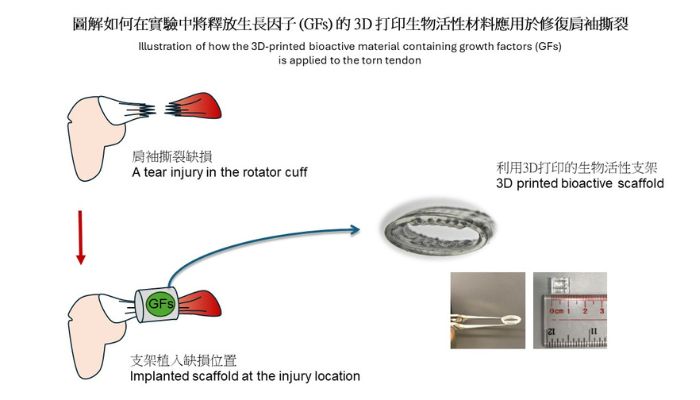

Results so far have been positive. Preliminary tests show that the material is able to effectively mimic tendons and restored the shoulder properties of injured rabbits back to healthy levels. Not to mention, it seems that the material can also deliver bioactive factors to regenerate at least 1 cm of a large tendon injury, something that has been considered impossible up to this point.

A graphic explaining how the process to heal rotator cuff injuries with the 3D-printable material (photo credits: CUHK)

Professor Elmer Ker, Assistant Professor in the School of Biomedical Sciences at The Chinese University of Hong Kong (CUHK)’s Faculty of Medicine (CU Medicine and leader of this research, concludes, “Our work has achieved the goal of developing an easily manufactured, mechanically robust, pro-regenerative tendon biomaterial that addresses mechanical and biological deficits in rotator cuff injuries while avoiding a complex and laborious production process. We will continue to prove the significant potential of this newly developed material for the repair of large-to-massive rotator cuff injuries, as well as other soft tissue injuries, in a clinical setting.” You can find out more in the recently published paper HERE.

What do you think of the use of a 3D printable material for massive rotator cuff tendon repair? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here for the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.