How can additive manufacturing respond in times of crisis? Experts give their advice!

The COVID-19 pandemic has shaken the global economy and the way we work, forcing us to rethink our current value chains, trade, production, and communication. The additive manufacturing sector is no exception, however it’s true that the market adapted very quickly to provide medical solutions during this emergency. Additive manufacturing technologies allow local production, faster iterations and shorter manufacturing times; in the face of such a crisis, these are key benefits. If additive manufacturing proved its effectiveness during the crisis, it is interesting to ask what will happen afterwards, during the gradual return to normal life. Will it be able to maintain such an important place in our manufacturing systems? Has the global crisis changed mindsets? What challenges remain to be solved and what lessons can we learn?

To answer these questions, we interviewed three industry experts who explained what this crisis has revealed for them and how they see the future of additive manufacturing. Sumeet Jain is Managing Director of 3D Printing Solutions by Arkema, the French group’s business dedicated to additive manufacturing. It has developed a polymer offering dedicated to 3D printing, whether for extrusion, powder bed sintering or photopolymerization processes. Our second expert is Mark Seaton, EVP of Global Sales at Link3D, a software platform that allows companies to streamline their additive manufacturing workflows. Finally, Thierry Rayna is Professor of Innovation Management at Ecole Polytechnique and is mainly interested in the impact of digital technologies on innovation and how they affect our business models.

- Sumeet Jain

- Mark Seaton

- Thierry Rayna

Additive manufacturing vs. COVID-19

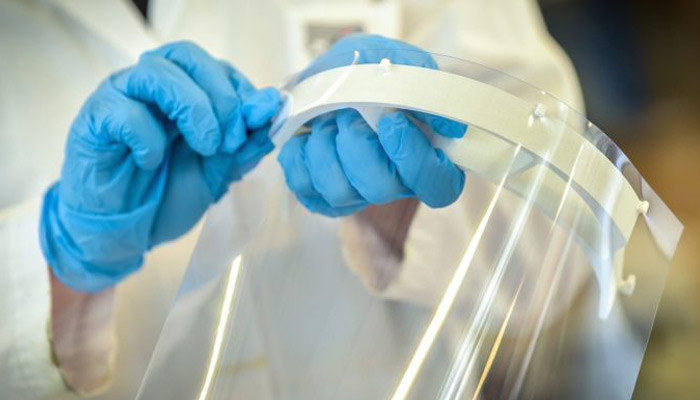

The last few months have been challenging in every respect for many. However, there has been a great deal of solidarity as demonstrated by the additive manufacturing market. All players mobilized to produce personal protective equipment (PPE), respirators or other medical solutions to protect and fight the spread of the virus. Sumeet Jain explains: “As our global supply chain of critical equipment got strained, it was immensely gratifying to see how everyone along the value chain came to the rescue using 3D printing technologies. Arkema helped the community in a variety of ways – Arkema manufactured materials were used by partners in manufacturing of nasal swabs, face shields and ventilator/respirator parts.” Additive manufacturing has addressed a number of challenges, including the disruption of our global supply channels.

Mark Seaton of Link3D agrees, saying, “As Covid-19 has disrupted supply chains on a global scale, it’s been amazing to see how additive manufacturing has stepped up. It is designed to help organizations optimize supply chains and empower distributed manufacturing.” Most companies have not been able to rely on their traditional supplier network, so an alternative had to be found, and that’s where 3D printing makes sense: it’s a more agile production method that reduces overall lead times. Sumeet Jain confirms, “The COVID crisis was an opportunity for 3D printing technology to demonstrate its value proposition around digital manufacturing and its ability to meet on-demand production needs. 3D printing companies across the ecosystem broke traditional boundaries and partnered openly to fast-track qualifications for PPE and testing applications. 3D printing’s ability to iterate hundreds of designs in short term was a key differentiation to develop viable solutions meeting unforeseen demand.”

For Thierry Rayna, 3D printing technologies have above all made it possible to adapt objects that already existed into medical solutions such as the famous Decathlon masks; he talks about repurposing: “What is most striking is the fact that 3D printing has been able to adapt things that already existed. But for me, the most interesting thing is what will happen next. Will the technology be as useful and present when world trade picks up again, assuming it goes back to the way it was before?”

Additive manufacturing helped produce face shields

“Post COVID-19”: What role can additive manufacturing play?

Additive manufacturing demonstrated its potential during the crisis, also revealing the limits of our current supply chains. What about afterwards? Most manufacturers are using the technology but it remains a niche market on the more global scale of manufacturing: how can we ensure that it becomes a must for our industry? According to Sumeet Jain, the technology still needs to overcome a few challenges before it can be adopted globally: “The major challenge that still needs to be overcome is standardization and reliability of products manufactured using 3D printing.” More certifications and standards need to be issued to meet the requirements of manufacturers and to move to a mass production dynamic. There are still too many printing errors and the preparation and post-processing stages are still too cumbersome. However, the market tends to develop more and more automation and flow management solutions to get as close as possible to a repeatable and reliable system.

Mark from Link3D completes: “We need to make this digital transformation complete through automated and predictive decisions for continual process optimization. We must capture and make sense of all the data produced from design through part delivery. Use this data to maintain standard and consistent quality produced parts at scale.”

For Thierry Rayna, it is above all a question of observing whether the changes caused by the current crisis are transitory or whether they are destined to last: as world trade has experienced friction, 3D printing has become profitable for many applications, both in terms of cost and, above all, time. As a result, this situation of reduced trade has favoured the use of 3D printing. When you buy an AM solution, you want your return on investment to be as high as possible: “We’re going to produce parts simply because we’ve got the equipment, which will lower the cost of the machine’s acquisition. So at least in a transitional period, we’ll tend to use 3D printing for things we didn’t before.” This leads to another factor: as companies use more 3D printing, they will use less international trade, which will lead to a surge in global transportation costs. This vicious cycle is ultimately virtuous for additive manufacturing because if these costs rise, they will tend to boost the use of 3D printing in the long term.

3D printing made it possible to adapt certain products: Decathlon diving masks were turned into respirators for example.

Additive manufacturing and uncertainty

How will 3D printing respond to economic uncertainty? We cannot be sure that the post COVID-19 world will look like the world we knew before – so what solutions can additive manufacturing bring? While it has many advantages in times of crisis – local production, responsiveness, agility, fast iterations, etc. – it also reduces risk in an uncertain economic context: a user can do almost anything with his machine, whatever happens, it will be able to run for many applications. “It reduces the risk because that production capacity that you have invested in can be used can always be used. Its return is ultimately higher in this uncertain environment.”

Governments also have a key role to play. This is where 3D printing provides an answer because it is much more flexible and adaptable than conventional methods. Thierry Rayna concludes: “This post-COVID-19 period does not necessarily imply that more companies will equip themselves with 3D printers, but that more will use them. It implies an increase in service providers: the more traditional ones will invest in 3D technologies. Finally, I think that post-COVID will increase the use of additive manufacturing, hopefully in the long term.”

One thing is certain, we will closely monitor the evolution of additive manufacturing in this post-crisis context and the responses it can bring to our industries. Let us know your thoughts in the comments below or on our Facebook and Twitter pages! Sign up for our free weekly Newsletter to receive all the latest news in 3D printing straight to your inbox!