3D printed hair from MIT could have many innovative applications

The Media Lab at MIT is renowned for applying additive manufacturing to some of the most unusual and inspiring projects. In January, we reported on MIT researchers developing the G3DP2 system, capable of 3D printing glass. The Massachusetts Institute of Technology invested in 2016 in a new project, Cilllia. The Tangible Media Group (part of MIT’s Media Lab) was behind this project, led by Professor Hiroshi Ishii. The group aims to “seamlessly couple the dual world of bits and atoms by giving dynamic physical form to digital information and computation”. Project Cilllia aspired to study the structure and purpose of hair. It is one of the applications of 3D printing not often talked about but could have many applications in the years to come.

Even though 3D printing has recently shown it can print pretty much anything, some things still defy the technology. This includes hair, fur, and other dense arrays of extremely fine features. These structures require a huge amount of computational time and power not only to design but also to print. The Tangible Media Group have found a solution to the design hurdles by using something different than the conventional CAD software used to create a 3D model. Instead of drawing thousands of individual hairs on a computer, the team built a new software platform called Cilllia.

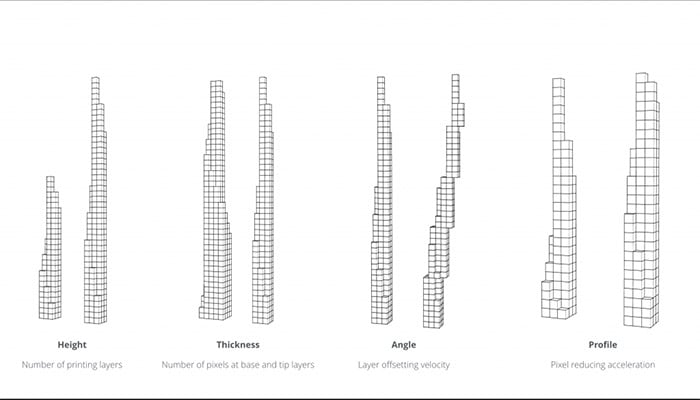

The software allows users to define the angle, thickness, density and height of thousands of hairs in just a few minutes. The designed arrays of hair-like structures have a resolution of 50 microns (width of a human hair). The team then experimented with different dimensions from coarse bristles to fine fur, onto flat and curved surfaces. They 3D printed these hairs using a conventional 3D printer.

The researchers see this technology having applications in tasks such as sensing, adhesion and actuation, rather than just to print wigs and hair extensions. For example, the team demonstrated adhesion by printing arrays that acted as Velcro-like bristle pads. Depending on the angle of the bristles, the pads could stick to each other with varying forces.

One of the graduate students in media arts and sciences that worked on the project, Jifei Ou, said that the work was inspired by hair-like structures in nature. In nature, human hair can provide warmth on the body or movement, as seen in the lungs to remove dust. “It’s very inspiring to see how these structures occur in nature and how they can achieve different functions. We’re just trying to think how can we fully utilise the potential of 3D printing, and create new functional materials whose properties are easily tunable and controllable”.

“Perhaps more inspiring than any single output from this team is the idea of rethinking the 3D printing process itself and the purpose of 3D printed objects,” says Schaefer, who was not involved in the research. “The Cilllia team has challenged some of the current constraints of 3D printing processes, which makes me wonder what other constraints can be challenged and potentially eliminated.”

More information can be found in the paper they published in 2016.

Let us know what you think in a comment on our Facebook and Twitter pages! Don’t forget to sign up for our free weekly Newsletter, with all the latest news in 3D printing delivered straight to your inbox!