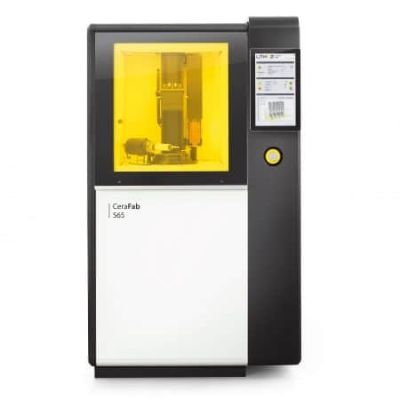

Austrian 3D printer and material manufacturer Lithoz, which specializes in additive manufacturing related to ceramics, launched its CeraFab System S65 in 2018. This 3D printer joins the CeraFab line alongside the CeraFab Lab L30, CeraFab System S25, CeraFab System S230, CeraFab Multi 2M30 and, of course, the CeraFab System Medical S65. The CeraFab System S65 is a flexible all-rounder that is suitable for almost any project and is especially designed for absolute precision. Digital industrial series production is supported thanks to the maximum productivity of the CeraFab System S65 and thus offers the user the possibility of networked mass production.

Features of the CeraFab System S65

Lithoz 3D printer’s high-quality workmanship, elegant industrial design, and intuitive usability make it ideal for industrial, aerospace, and research and development applications. Through the use of cascading, an increase in 3D printing productivity is easily achieved. More specifically, this includes the modular design of up to 4 manufacturing units, a production safety and risk minimization by splitting the production and also by a higher build speed with the same precision.

In addition to its build envelope size of 102 × 64 × 320 mm, the ceramic 3D printer also includes build envelope heating and air conditioning, with the overall build envelope being vibration damped. With a build speed of up to 150 layers per hour, users are enabled to keep an eye on their 3D printing at all times through real-time online monitoring and full print job documentation. Parameter changes are also possible during printing.