The CeraFab System S25 comes from Lithoz, an Austrian manufacturer of 3D printers and materials that focuses on ceramics and offers additive manufacturing solutions for everyone from beginners all the way through users who need industrial series production. In addition to the CeraFab System S25, the CeraFab System, S65 and S230 and the CeraFab Multi 2M30 and CeraFab System Medical S65 also join the product portfolio. The CeraFab System is the answer to the need for industrial series production with additively manufactured high-performance ceramics. The modular design of the CeraFab System allows the combination of up to 4 manufacturing units – to form a large production plant. Productivity can thus be increased many times over compared to a single machine and failure risks can be minimized proportionally.

Features of the CeraFab System S25

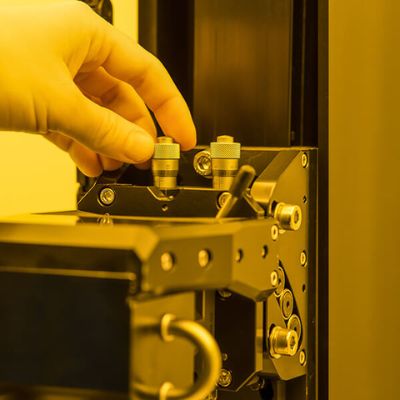

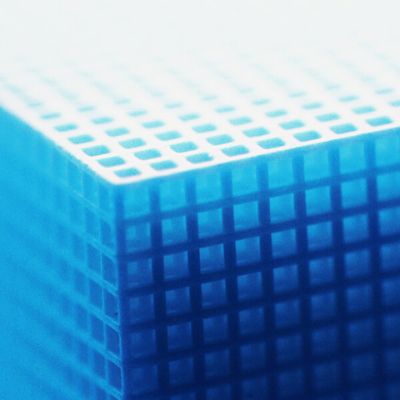

The CeraFab S25 printer is uncompromisingly designed for microstructures. In the series of CeraFab System 3D printers, the S25 takes on the role of the detail-oriented specialist. With a slightly smaller build platform, the LCM technology is optimized for the highest possible perfection and accuracy. Additionally, the printer has the most compact build platform of all System printers, but in terms of exposure accuracy it reaches unique dimensions. Indeed, the 3D printer has a build volume of 64 x 40 x 320 mm, while its overall machine size is 1.05 x 0.85 x 1.78 meters.

Lithoz’s CeraFab System S25, which uses Lithoz’s own high-quality LCM (Lithography-based Ceramic Manufacturing) manufacturing technology, is compatible with ceramic materials. With its ability to print 150 layers per hour, it additionally convinces beginners with its layer thickness of 10 – 100 µ . The CeraFab System S25 steps into the front row when it’s not about quantities or maximum profitability. Its clear mission is to explore the capabilities of LCM technology to the utmost in terms of microstructure fineness and complexity. A central element of the CeraFab system is the database-supported storage and processing of all process data, enabling seamless documentation of print jobs. Optional software upgrades allow even better parameter management, parameter adjustment or structuring of your production data as well as the possibility of real-time process control via live video remote transmission.