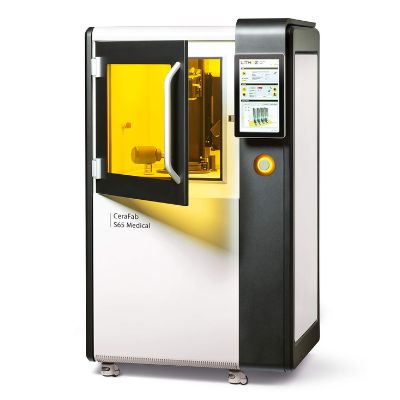

The CeraFab System Medical S65 is another offering from Lithoz, an Austrian manufacturer of ceramic 3D printers and materials that offers additive manufacturing solutions for everyone from beginners all the way to those who need industrial series production. In addition to the CeraFab System Medical S65, the CeraFab System S65, S230 and S25 and the CeraFab Multi 2M30 also join the product portfolio. The CeraFab System is the answer to the need for industrial series production of additively manufactured high-performance ceramics. The modular design of the CeraFab System allows the combination of up to 4 manufacturing units – into one large production line. Productivity can thus be increased many times over compared to a single machine and downtime risks can be minimized proportionally. A central element of the CeraFab system is the database-supported storage and processing of all process data, enabling seamless documentation of print jobs. Optional software upgrades allow even better parameter management, parameter adjustment or structuring of your production data as well as the possibility of real-time process control via live video remote transmission.

Features of the CeraFab System Medical S65

Precisely tailored to the demanding conditions in the medical and dental field, the S65 Medical translates these high requirements into impressive results. With the CeraFab S65 Medical, a very specific goal has been achieved: to transfer economical, networked series production to the high demands of medical applications, while at the same time bringing the full potential of LCM technology to individual, transition-free customization in the service of medicine. With the CeraFab S65 Medical, Lithoz offers medical and dental research and industry the highest possible standard of ceramic 3D printing. From jawbone implants to perfectly fitted crowns, numerous materials open up 3D printing to the full range of ceramic medical applications. Ceramic dental restorations made of lithium disilicate are superior to other materials in both cost-effectiveness and the natural appearance of the human tooth. Studies confirm that this material can be additively manufactured with Lithoz LCM technology for the first time in equal quality and grade.