#3DExpress: Sintratec Announces Closure Following Bankruptcy

We are back with #3DEXPRESS to show you all the highlights of the news from the additive manufacturing sector this week! First, after a decade of business, Sintratec has begun to cease operations as of May 7th, 2024. Next, Massivit takes a leap forward with the introduction of its Massivit 3000 large-format 3D printer. Moving forward, Inkbit secures $19M in funding led by Ingersoll Rand, bolstering its Vision-Controlled Jetting technology. Next, Lithoz joins the Manufacturing Technology Center (MTC) to promote ceramic 3D printing for industrial end users in the UK. Lastly, Dyndrite celebrates a significant milestone with a $1.3 million award from America Makes, dedicated to enhancing LPBF Operational Qualification through cutting-edge Software Automation. Enjoy and have a great weekend!

Sintratec Announces Closure After Bankruptcy

Swiss SLS solution manufacturer Sintratec has announced that after a decade in business, it will be ceasing operations as of May 7th, 2024. The company was well-known for being one of the first to launch a desktop SLS 3D printer, the Sintratec Kit, back in 2014. Since then, the company has produced other solutions, including the Sintratec S2 and S3. In a joint statement from co-founders Dominik Solenicki and Christian von Burg, they stated, “We thank our customers, partners, investors, and our team for their trust, support, and dedication over the years. Sintratec’s journey may be concluding, but its spirit will persist through the applications it enabled and the ground it broke.” According to Sintratec, the priority now is to reduce disruption for customers and resellers. As such, French reseller KREOS handles the provision of spare parts and printing materials to customers based in the EMEA region and 3DChimera, Sintratec’s U.S.-based reseller, extending services to U.S. customers and the rest of the world.

A part made with a Sintratec SLS solution (Photo Credits: Sintratec)

Massivit to Unveil New Affordable, Large-Format 3D Printer

Massivit has announced that it will be launching its new Massivit 3000 large-format 3D printer, the Drupa tradeshow, in Dusseldorf, Germany. The goal of the new machine is to offer a more affordable, large-format FDM solution for ultra high-speed production in applications like 3D window displays, dimensional billboards, custom channel letters, 2D/3D combined point-of-purchase displays, interactive event props, theme park scenery and molds for thermoforming. The printer has a print volume of ~1.2 x 1.5 x 1.8m (4 x 5 x 6ft), a truly large size for an extrusion solution. Erez Zimerman, the CEO of Massivit, confirmed, “We are very excited about the launch of the Massivit 3000, which marks a significant milestone for Massivit. Our contributions to the advertising and entertainment markets have already been substantial, with the delivery of large-format 3D printing capabilities at unprecedented speed. The introduction of the new Massivit 3000 extends access to this disruptive technology to a much wider range of companies, offering excellent value for money. The highly anticipated global Drupa show is the perfect platform for unveiling our new printer to these markets.”

(Photo Credits: Massivit)

Inkbit Secures $19M Funding Led by Ingersoll Rand for Vision-Controlled Jetting Technology

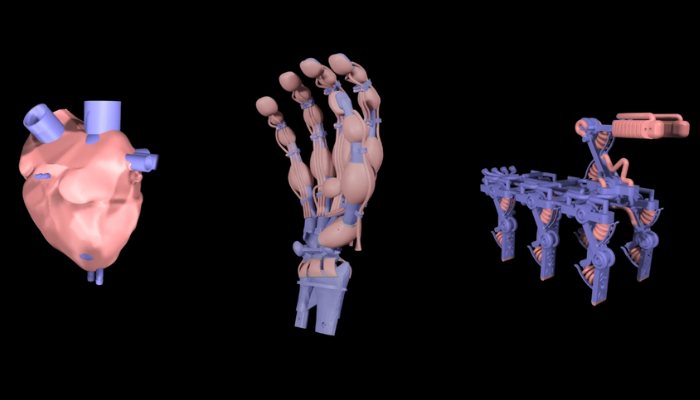

Inkbit, a leader in advanced 3D printing solutions, has successfully concluded a $19M financing round, prominently backed by Ingersoll Rand, among other notable investors. This investment will serve to fuel Inkbit’s development of its Vision-Controlled Jetting (VCJ) technology, which revolutionizes traditional assembly lines by integrating 3D machine vision-based feedback control. The VCJ system, developed by MIT’s Computer Science and Artificial Intelligence Lab, offers improved flexibility and reliability while enabling multi-material, single-pass production from raw materials. With the addition of industry experts like Jason Weber from Ingersoll Rand and Henry Ford III from Ford Motor Company joining Inkbit’s board, the company aims to accelerate the adoption of VCJ across various significant sectors. Inkbit projects that widespread implementation of VCJ will have a longstanding positive impact on product design and manufacturing across robotics, healthcare, mobility, and defense, streamlining complex supply chains and assembly processes.

(Photo Credits: Inkbit)

Lithoz Joins the UK Manufacturing Technology Center

Lithoz, a leading additive manufacturing company for ceramics, recently joined the Manufacturing Technology Center (MTC) to promote ceramic 3D printing for industrial end users in the UK. Through Lithoz’s new membership, MTC aims to expand its range of AM options for various industries. MTC engineers will use Lithoz’s CeraFab S65 machine to process a variety of high-performance ceramics, enhancing MTC’s ability to design and produce complex ceramic geometries. “[We’re] very excited to be working with Lithoz using their advanced CeraFab system to push the boundaries of ceramic AM across sectors, including power, energy, and defense,” said Sherry Ghanizadeh, Senior Research Engineer at MTC.

(Photo Credits: Lithoz/MTC)

Dyndrite receives $1.3 million America Makes award to improve LPBF Operational Qualification

Dyndrite, a provider of GPU-accelerated computing engine for digital manufacturing, has been awarded by America Makes, the National Additive Manufacturing Innovation Institute, and the National Center for Defense Manufacturing and Machining (NCDMM) for the project “Improving LPBF Operational Qualification (OQ) through Software Automation.” This $1.3 million project aims to optimize the Operational Qualification (OQ) process of LPBF technology. Currently, qualification processes in metal additive manufacturing are complex, manual, and error-prone, resulting in long lead times, exorbitant costs, and variable results. The award-winning project, which also involves Siemens Energy and ASTM International’s Additive Manufacturing Center of Excellence (AM CoE), will demonstrate and provide commercial solutions for simplified and automated OQ methods for Laser Powder Bed Fusion (LPBF). “This project represents not just a step forward but a significant leap for the entire industry, promising enhanced efficiency and improved quality across the board,” says Richard Huff, director of Industry Consortia and Partnerships at ASTM International.

(Photo Credits: Dyndrite)

What do you think about the closure of Sintratec last week? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here for the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.