Voxeljet is a German company based in Friedberg, Hesse, that has been working on 3D printing solutions for more than 20 years. It has an extensive product portfolio, which includes the VX200 HSS 3D printer, the VX1000, the VX1000 HSS or even the VX1300 X, among others. Like most of voxeljet’s 3D printers, the VX200 HSS (High Speed Sintering) is intended for industrial manufacturing and is, according to the manufacturer, one of the most flexible 3D printing systems for polymers.

Features of the VX200 HSS

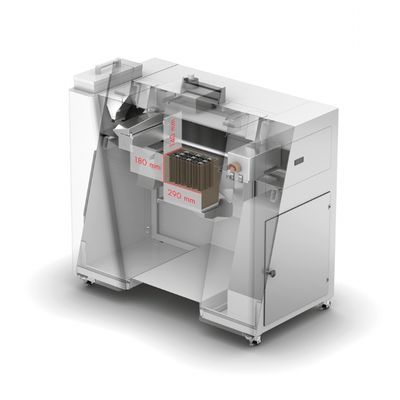

With a maximum printing volume of 300 x 200 x 150 mm, this 3D printer was introduced to the market in 2021. Thanks to the binder jetting technology, parts with a maximum length of 290 mm can be 3D printed at a resolution rate of 360 dpi. It is a material-tolerant 3D printer, as it allows the user to use most custom polymers. This use of material diversity is also supported by the open source software, which allows full access to all kinds of printing process parameters and temperature source settings, allowing you to customize the configuration for each material. By default, the VX200 prints HSS 12 polyamide, but other polymers such as polypropylene (PP) or TPU can be used on request.

As for the voxeljet machine’s applications, it can be used for material development and polymer research. The VX200 HSS machine can also be used to produce prototypes, regardless of whether they are parts for design evaluations, ergonomics or technical functions. The machine’s precision is particularly useful in this case. Finally, the 3D printer is also used for the production of spare parts, as it enables rapid centralized or decentralized production for single parts or even small series.

The printer comes equipped with easy-to-use and intuitive software, making printing a simple operation for all users. This makes it ideal for use in educational institutions like universities.