Following the launch of the Tritone Dominant 3D printer, the Israeli company (also named Tritone) introduced its Tritone Dim in 2021. This machine, also like its counterpart, is a 3D printer designed for industrial use, using its own patented MoldJet technology. It is important to mention that this is a powder-free process that can produce parts from metals and ceramics on an industrial scale, and at high speed at the same time. Notably, the possibility of a quick and easy change between metals and ceramics make this process particularly attractive for users.

Features of the Tritone Dim

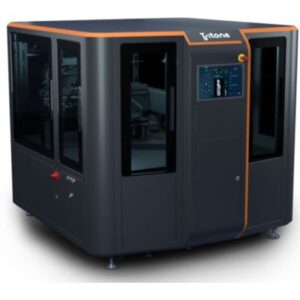

If we talk about the installation space of the Tritone Dim, it should be noted that the area of 220 x 120 x 90 mm is divided into more than four inserts, which are independent of each other. As for the overall size of the 3D printer’s hardware, it is 2150 x 1960 x 1800 mm and weighs in at 1,300 kg. Unlike its colleague the Tritone Dominant, the Dim is quite a bit smaller, but also lighter.

When it comes to 3D printing with the Tritone Dim, it is important to note that the nominal layer thickness is between 50 and 100 µm. As far as printing with supports is concerned, the manufacturer specifies the company’s own Tritone Mold material for this. After the finished print, the user subsequently receives components from the Tritone Dim that feature both fine details and a smooth surface quality. In addition, extremely complex part geometries can be produced with high print resolution and precision.