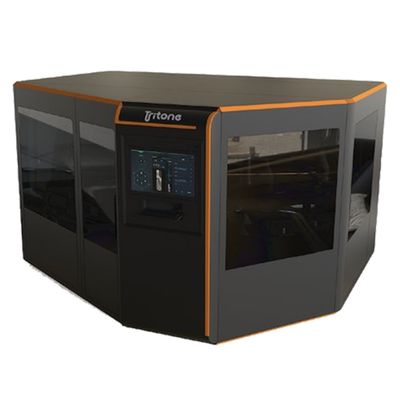

In addition to the Tritone Dim, the 3D printer portfolio from Israeli manufacturer Tritone Technologies also features the Tritone Dominant. Launched in 2019 and developed for industrial use, this 3D printing machine is particularly suitable for the additive manufacturing of metals and ceramics, according to the company. To do this, the Tritone Dominant uses MoldJet, a technology developed in-house. This is a powder-free 3D printing method that can process both metals and ceramics on an industrial scale and at extremely high speeds. It is particularly well suited to the production of complex geometries, high density and mechanical properties.

More Features of the Tritone Dominant

Spread over six independent inserts, the build volume of this 3D printer comes to a total of 400 x 240 x 120 mm; the overall hardware size of the Tritone Dominant is 3200 x 2200 x 1900 mm and includes a weight of 2,300 kg. The nominal layer thickness is between 50 and 100 µm. The simultaneous process exceeds throughput of 1600 cc/h.

As for the support structures needed for printing, the manufacturer recommends the use of Tritone Mold proprietary material. This can eventually be used to produce a range of parts with a wide choice of materials. These material choices include titanium, stainless steels, tool steels, copper alloys and more. The resulting parts feature not only fine detail but also smooth surfaces, with users able to vary in size from two meters to 350 mm long parts. Furthermore, the final sintered parts have a density of up to 99% and can range in size between 2mm to over 400mm. Another important feature of the Tritone Dominant is that it has automatic layer correction, which checks and controls the quality of the individual layers in real time so that no errors can occur during 3D printing.