Since its foundation in 1923, the German family-owned company ARBURG GmbH + Co KG, located in Lossburg, Baden-Württemberg, has been dedicated to the production of all-round injection moulding machines, turnkey solutions, as well as machines for industrial additive manufacturing. Among these, its portfolio includes the Freeformer 200-3X and the Freeformer 300-3X as well as the Freeformer 750-3X. The basic differences between all these machines relate primarily to the size and number of discharge units. The Freeformer 750-3X was introduced to the market in October 2022.

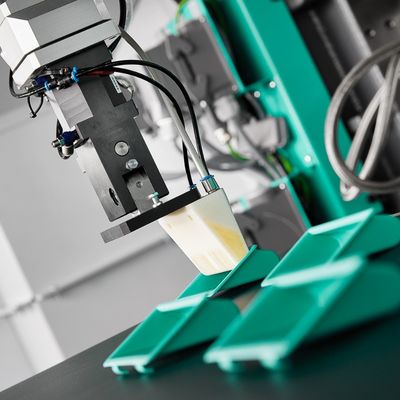

Characteristics of the Freeformer 750-3X printer

To explain, the name of this 3D printer is derived as follows: the number 750, like its 3D printer peers, refers to the build area available to the user, measured in square centimeters. In direct comparison to the Freeformer 300-3X, the 750-3X now offers 2.5 times more space for the production of parts that can have dimensions of up to 330 x 230 x 230 mm. The 3X stands for the total axes of the part carrier moving in the x, y and z directions.

When it comes to the materials to be used, which are plastics, it is important to mention that the Freeformer 750-3X is capable of printing flexible material as well as color combinations. Particularly noteworthy here is also the possibility of a hard-soft combination of the parts produced. With regard to material preparation, it can be added that this integrated application melts the standard granulates, just as in injection molding, which is one of ARBURG’s core competencies. Whether for individual parts or even for the production of small batches – the Freeformer 750-3X is suitable for both areas.