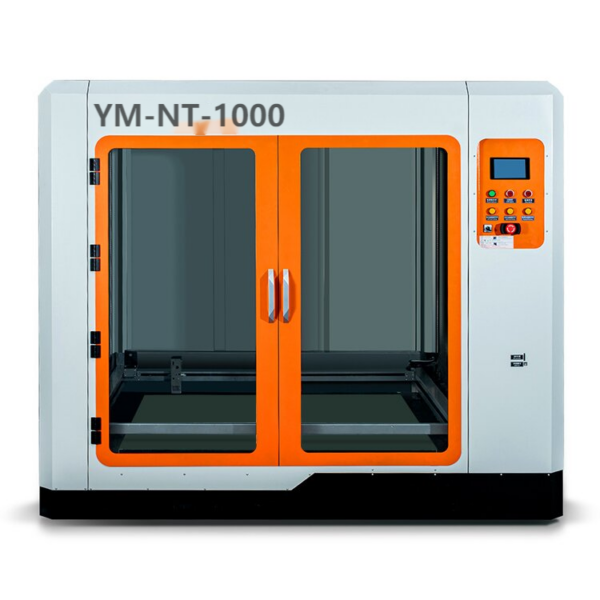

The Chinese company IEMAI 3D offers complete solutions for industrial 3D printing that are compatible with a wide variety of materials. The manufacturer thus meets the needs of various application areas, including the automotive, aerospace and medical technology industries. The solutions are also used in the electrical and oil industries. Like most machines from the Asian manufacturer IEMAI 3D, the YM-NT-1000 3D printer uses FDM technology. This quality solution is capable of producing parts with a wide range of engineering plastics.

Features of the YM-NT-1000 3D Printer

The YM-NT-1000 3D printer features automatic plate leveling, end-of-filament detection and the ability to resume printing in the event of a power failure. Its maximum printing volume is 1000 x 1000 x 1000 mm, making it one of the manufacturer’s largest models. This makes the 3D printer particularly suitable for large prints. With a machine size of 1890 × 1450 × 1600 mm, the 3D printer weighs 700 kg, while the printing speed reaches 150 mm/sec. The list of materials the solution can work with is long. These include technical polymers such as PLA, ABS, PA and PC.

The YM-NT-1000 3D printer also has a removable structure and interchangeable heads. The 1.75mm extrusion system consists of a dual head extruder for two-color 3D printing. The 2.85 mm extrusion system, on the other hand, has a single nozzle. Maintenance of the system is particularly easy to manage thanks to the modular mechanism on the extruder. With regard to process temperatures, the extruder temperature is 275 °C and the platen temperature can reach 120 °C. In addition, a filament compartment that protects against moisture must be used.

The manufacturer recommends using the company’s slicing software, IEMAI3D EXPERT. However, the YM-NT-1000 3D printer is also compatible with other software such as Cura, Prusa, S3D or Simplify3D. The process can be monitored with a camera and the consumer is notified as soon as there is not enough filament left.