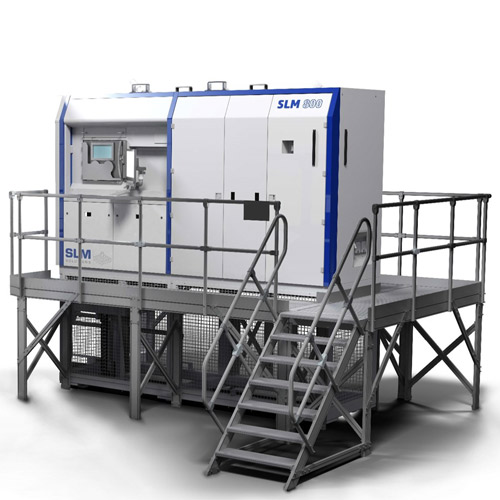

SLM Solutions, a German manufacturer, is a pioneer in laser powder bed melting technology and one of the first companies to develop 3D metal printing solutions using multiple lasers. The company offers industrial machines for demanding industries that can produce high-quality and detailed parts. The SLM®800, which has a larger printing plate for larger scale production, is one of the metal 3D printers in their product line.

Characteristics of the SLM®800 3D printer

The SLM®800 3D printer has a print volume of 500 x 280 x 850 mm, making it one of the largest machines in their product line. The size of the machine depends on the user’s configuration, but it is still very large. The SLM®800 3D printer uses four 400W or 700W lasers, depending on the user’s needs.

SLM Solutions designed this machine with affordable and automated manufacturing in mind, with a focus on safer and more efficient powder management. The machine has a central powder supply unit with two 220-liter tanks: one for supplying the machine with powder and the other for refilling. Between them are sieves to ensure powder homogeneity and quality. The machine also has a system that ensures a controlled gas flow to perform the depowdering process in an inert atmosphere.

The SLM®800 has a monitoring system to ensure the printing process runs smoothly. The temperature of the pressure chamber, gas flow, and oxygen content are all monitored and recorded to ensure optimal safety.

The SLM®800 is compatible with a wide range of metals and alloys, and SLM Solutions strives to collaborate with customers to develop new materials that meet various needs.