Free Float, SLM Solutions’ Software to Reduce Metal 3D Printing Support Structures

SLM Solutions, a leader in the field of metal additive manufacturing, recently unveiled its latest innovation: Free Float. This software reduces the amount of 3D printing support materials needed to build a part. As a result, users will be able to produce parts that were once unfeasible to create in terms of design and complexity. Furthermore, Free Float will significantly reduce build time while also allowing users to design quality components. In eliminating some or all of the printing supports, SLM Solutions aims to increase the productivity of any manufacturer while reducing the cost of powder and post-processing.

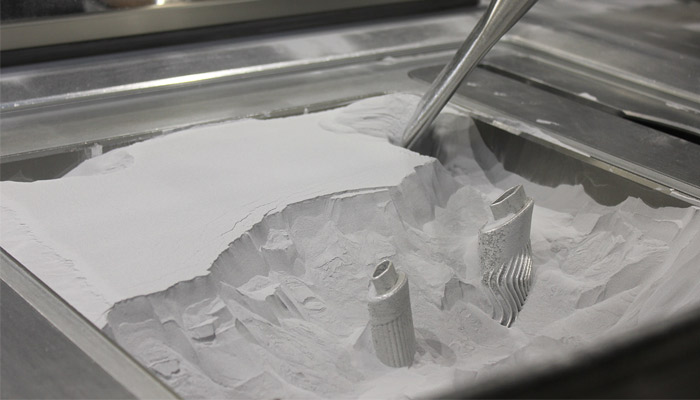

Traditionally, metal additive manufacturing requires the use of printing supports — this allows structures to be temporarily buttressed, with cantilevers absorbing excess heat to prevent damage or distortion to the part being built. However, these supports present many challenges. Users must take supports into account from the design stage and must also remove them in the final stage, thereby lengthening the overall manufacturing process. Additionally, supports require the use of more powder, which cannot be reused. In all, these challenges increase the cost of labor and materials, which is why in 2017 SLM Solutions started to think about a fix that would make it possible to minimize these supports and offer more design freedom.

Print media increases post-processing times. (Photo Credit: APWorks)

Free Float Increases Efficiency of Metal Additive Manufacturing

To solve the supports challenge, SLM Solutions created the Free Float software, which is can be installed on many previously built systems including the SLM®280 Production Series, SLM®280 2.0, SLM®500, SLM®800, and the NXG Xll 600. The software is based on vector technology that improves thermal management, reduces printing times, and increases part quality. Free Float begins with an .slm file (i.e. a geometry ready to be cut layer by layer). Three profiles can then be applied: low, medium, and high. The first profile allows for a smoother surface and less porosity, with a reduction of the necessary supports on the sections with non-critical angles. The high profile will reduce supports while considerably increasing the quality of the part.

Sam O’Leary, CEO of SLM Solutions, added, “With the launch of Free Float, you can design bolder, freer, and with fewer limitations. Today you can work faster and more productively.” During the product launch, he stated that the software would be free, and continued, “Free Float is a game-changer that will enable success and shouldn’t be limited regarding accessibility.” You can find more information in the official SLM Solutions press release HERE.

Three profiles are available depending on the quality of the part sought (Photo Credit: SLM Solutions)

What do you think of SLM Solutions Free Float software? Let us know in a comment below or on our Facebook and Twitter pages. Don’t forget to sign up for our free weekly newsletter, with all the latest news in 3D printing delivered straight to your inbox!

Cover Photo Credit: SLM Solutions