The x500eco is a cost-effective 3D printer from Germany’s innovatiQ for entry into industrial 3D printing. Like its other printers TiQ 5, x400, x1000 and MiQ 5, it runs on the fused filament manufacturing (FFF) process. Importantly, it is an open material system, which means it does not have to commit to a material manufacturer. As for the name of the 3D printer, this is derived from the dimensions, as with an installation space volume of 90 liters, it covers a size of 500 x 400 x 450 mm. Speaking of the installation space, it is important for the user to know that it can be heated to a temperature of 80 °C in a short time, about 12 minutes. This makes it possible to process technically demanding materials that are required for the production of high-strength structural and functional parts. The maximum print head temperature for the x500eco is 400 °C.

Other Features of the x500eco 3D Printer

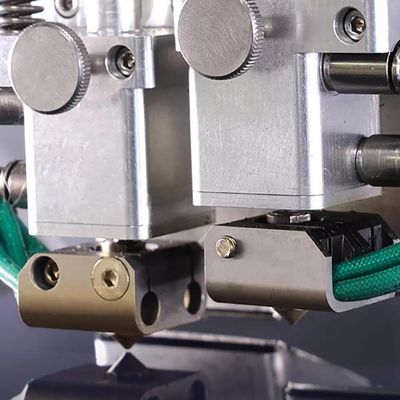

As for the extruder, the x500eco uses a water-cooled DD4 twin extruder, which ensures user-friendly operation. In addition, you can also benefit from the high process reliability, as it guarantees constant precision during the printing process, even in continuous operation! Added to this is the possibility of using two materials with process reliability. You can choose from the nozzle options of 0.25, 0.30, 0.35, 0.50, 0.60 and 0.80 mm; the filament you use must have a diameter of 1.75 mm. The x500eco is also equipped with a filament feeding and tracking system, which allows the user to significantly improve process reliability. The material feed rate is monitored and, in case there is no more material available, the material is automatically stopped. In addition, this system provides automatic print speed regulation based on the difference between the target speed and the actual speed.