9T Labs raises $4.3 million to advance carbon fiber 3D printing

Zurich-based startup, 9T Labs has successfully closed a $4.3 million funding round to finish the development of their industrial 3D printing solution. We told you before about the company’s activities in the 3D printing sector and their solution for composite materials. In fact, 9T Labs has created an add-on system for ordinary 3D printers to enable continuous fiber 3D printing. The industry is gaining confidence in continuous fiber 3D printing, particularly for industrial applications where this technology can add strength to parts without adding weight. Therefore, this investment will also allow the startup to scale-up the first mass manufacturing industrial use cases.

More precisely, 9T Labs works with carbon fiber composites, the most popular fiber in the 3D printing industry. Their technology is called Additive Fusion Technology (AFT) and as mentioned, it can be added to other systems seamlessly. The company was founded by Chester Houwink, Giovanni Cavolina and Martin Eichenhofer in 2018, and its mission is to make carbon fiber composite materials as accessible as ordinary metal materials.

Martin Eichenhofer, Chester Houwink, Giovanni Cavolina | Credits: 9T Labs

Many manufacturers are comparing carbon fiber 3D printed parts to metal 3D printed parts, the main difference being cost. When we spoke to the 9T Labs team at the end of last year, they told us: “Just imagine a material which is as lightweight as plastic but as strong, or even stronger, than metal. However, the traditional and established manufacturing routes are still limiting a widespread adoption of this performance material, mainly because of extremely long and expensive development times as well as a lack in automation.”

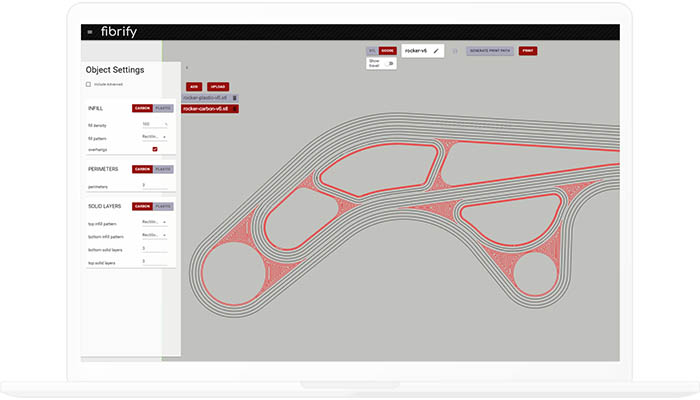

9T Labs provides 3D printing systems for continuous carbon fiber 3D printing and their Fibrify software to automate the production process. The software allows to optimize parts, resulting in extremely lightweight parts at a competitive price. They added: “Commonly the structural weight can be reduced by more than 50%, saving cost and resources. However, having just a highly optimized and 3D printed part is not enough to transform this industry for series production parts, it also requires a printed part quality which is comparable to parts manufactured by traditional processes.”

The Fibrify software can monitor your printing activity and optimize the fiber placement | Credits: 9T Labs

To achieve the ambitious goal of making carbon fiber 3D printing accessible to all in the 3D printing industry, this investment will be essential. Investors on this seed round included Wingman Ventures and new contributions from Investiere and the Technology Fund. Furthermore, 9T Labs is supported by the ESA BIC program. Andreas Wuellner, with more than 17 years working in the composites industry serving automotive, industrial, and aerospace markets added: “Knowing from experience what limits the widespread adoption of advanced fiber composite solutions, I found 9T Labs’ integral technology approach to overcome such limitations, fostering the adoption in mass manufacturing, very convincing.”

This composites industry is expected to grow tremendously and we can’t wait to see how companies develop in this space! You can find more information on 9T Labs’ website. What do you think of this investment? Let us know in a comment below or on our Facebook and Twitter pages! Don’t forget to sign up for our free weekly Newsletter, with all the latest news in 3D printing delivered straight to your inbox!