Zortrax is launching a third generation industrial 3D printer

Zortrax is launching a third generation industrial 3D printer, designed for industry and production lines. It is named Endureal and will be unveiled at the TCT Show in Birmingham between the 24th and 26th of September. For Zortrax, this is a new and bold move. It is true that the 3D printing market is moving away from using additive manufacturing for rapid prototyping purposes only. Instead, the market is adopting industrial solutions that will enable large-scale production. At the beginning of the year, a survey initiated by Essentium revealed that 57% of respondents expected future production runs to be in the thousands of parts – a growing percentage.

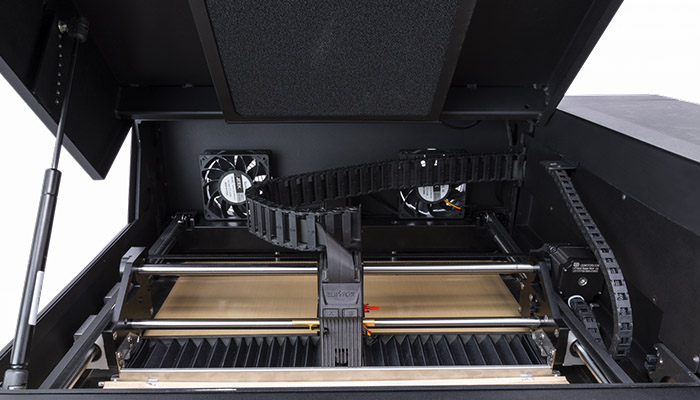

As for the Endureal 3D printer, it has been designed for advanced engineering and medical applications – designed for a future of effortlessly-operated manufacturing lines. It showcases a volume of 36 liters and the device measures 30 x 40 x 30 cm. You can use it in dual and single extrusion modes with Zortrax’ LPD Plus technology. As for the build plate, it is made of ferritic stainless steels covered with PEI film so that all supported filaments adhere properly and models are easy to remove. In high-volume production, this is a crucial feature.

Image via Zortrax

Moreover, the new solution provides advanced thermal management, filament temperature is tightly controlled at each stage to achieve high-precision and the best possible mechanical properties for 3D printed parts – making it compatible with high-performance materials such as PEEK. PEEK’s unique properties include high wear resistance, excellent thermal properties, proven biocompatibility, a great strength-to-weight ratio and high radiation resistance. These features are important for the medical sector as well as aerospace, automotive and mechanical engineering.

To achieve the best possible print quality, the thermally-shielded extruder compartment is always kept at the right temperature, avoiding interruptions in filament transmission. Additionally, the Zortrax Endureal has 17 built-in sensors that work in real-time and measure the operation of the printing job. Printing can be monitored remotely using a camera installed in the chamber of the 3D printer. Designed to work at high temperatures, the camera can stream live videos.

Image via Zortrax

Finally, if a power outage is detected, the Blackout Response System uses energy stored in built-in capacitors to save the exact position of the printing head. Once the power is back on, printing can resume from the same spot. Separate sensors are constantly working to detect problems, such as a jammed or depleted filament. The printer also monitors filament spools’ weight to check whether there is enough material to complete the model. The temperature and humidity in the filament compartment is measured and controlled at all times, crucial during long 3D printing projects with highly.

What do you think of Endureal 3D printer? Let us know in a comment below or on our Facebook and Twitter pages! Don’t forget to sign up for our free weekly Newsletter, with all the latest news in 3D printing delivered straight to your inbox!