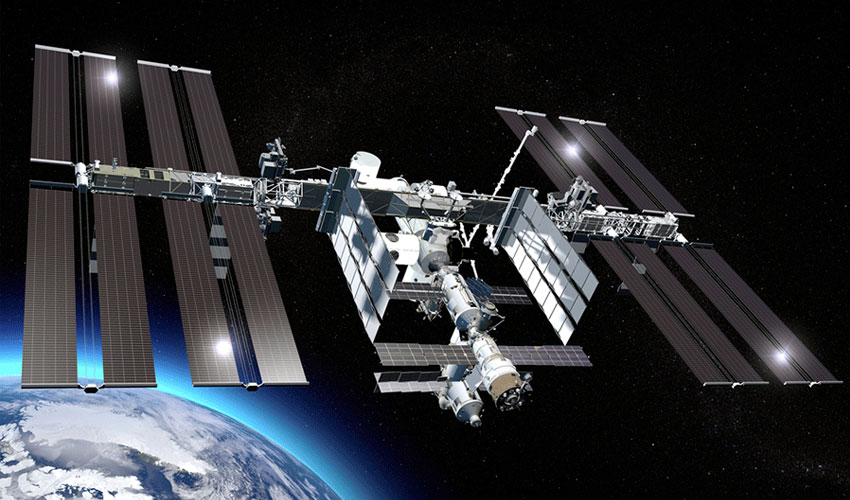

Zero Gravity Bioprinter: Ready for the International Space Station

The additive manufacturing has become a great ally for the extraterrestrial conquest and for the technological development in space. There are multiple applications of 3D printing for arrival in space, but there is one that has stood out in recently: the Zero Gravity bioprinter, is capable of developing living tissue in zero gravity.

The idea of printing in space without gravity came with the US company Made in Space and NASA, which succeeded in 2014. A couple of years ago the companies Techshot and nScrypt came together to print a 3D human heart to gravity zero. Showing that bioprinting is much more effective and controlled under these conditions or outside the Earth. It is very likely that the first functional organ printed in 3D is obtained outside of our planet.

The Zero Gravity bioprinter could make the first functional organ in 3D

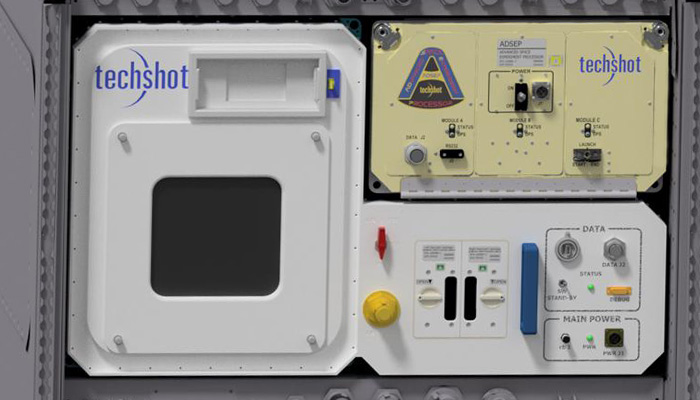

After the first success, the American companies nScrypt and Techshot began the development of the 3D BioFabrication Facility, or BFF, a bioprinting system for the International Space Station. Its technique allows 3D printing of thick tissue and organs using adult stem cells. The manufacturing is done through the Zero Gravity bioprinter also called Bio Assembly, or BAT and the biotintas will be used in the cell culture bioreactor that is conditioned by the Advanced Space Experiment Processor TechShot (ADSEP). The BFF and the ADSEP technique hope to launch on the Space Station in 2019.

The BAT bioprinter has very precise movements and control of extreme dispensation, will use SmartPump, patented nScrypt technique, which has a volumetric control of 100 picolitres and will use superfine nozzles of up to 10 microns for the extrusion of biomaterials.

Rendering of BFF technology by nScrypt

“Especially when it comes to something as important as weaving, it’s vital to put the right amount of material in the right position every time,” said nScrypt CEO Ken Church. “This is what our machines offer and what has contributed to our success in bioprinting, as well as in other applications.” This is an exciting time for discovery and, most importantly, a moment of impact for those seeking Serious solutions to develop thick vascularized tissue, which is the basis of a fully printed organ. “

It is expected to begin with bioprinting of cardiac tissue patches (photograph University of Wisconsin)

The first thing they hope to achieve with the Zero Gravity bioprinter will be a cardiac patch , for the recovery of hearts. The cells will be printed in the bioreactor, and the bioreactor will provide perfusion of the media to release nutrients and remove toxins from the tissue, keeping it alive while providing electrical and mechanical stimuli to encourage cells to beat.

“We are very excited to see this project, and everything it can provide and come to life,” said Techshot President and CEO John C. Vellinger. “With the goal of producing everything from organs to pharmaceuticals, to maybe even food, BFF has the ability to improve the lives of people on earth and help enable exploration of deep space.”

What do you think about the developments of the Zero Gravity bioprinter? Drop a comment below or on our Facebook and Twitter page. And don’t forget to sign up to our free weekly Newsletter to keep updated on all the latest news in the 3D industry coming straight to your inbox!