XYZprinting’s SLS Technology: An Ideal Choice for Drone Manufacturing

TEKEVER is a Portuguese company that designs and manufactures maritime surveillance drones for the defense and security sectors. Since 2001, it has been developing unmanned aerial systems (UAS), offering more precisely a range of three products, the AR3, AR4 and AR5. The one drone we are particularly interested in is the AR4 because it integrates a 3D printed component made with an SLS machine from XYZprinting. By using the MfgPro230 xS 3D printer, the company was able to design the body of its drone’s turret while reducing its costs and lead times. All while respecting the mechanical requirements and properties of the part.

The development of UASs involves a number of constraints: its components must be strong and impact resistant, but also light and rigid in order to ensure better performance. Using additive manufacturing to produce these parts can meet these expectations – the technology is indeed already widely proven in the aerospace field. By using only the necessary material and the right material, it is possible to optimize the weight/strength ratio of a part while reducing manufacturing time. This is one of the reasons why TEKEVER has taken a closer look at 3D technologies. It first turned to fused deposition modeling (FDM), but the process had some limitations, which led it to test other technologies. The company finally opted for a selective laser sintering (SLS) solution from XYZprinting, among other reasons due to the superior mechanical properties that SLS technology offer compared to FDM.

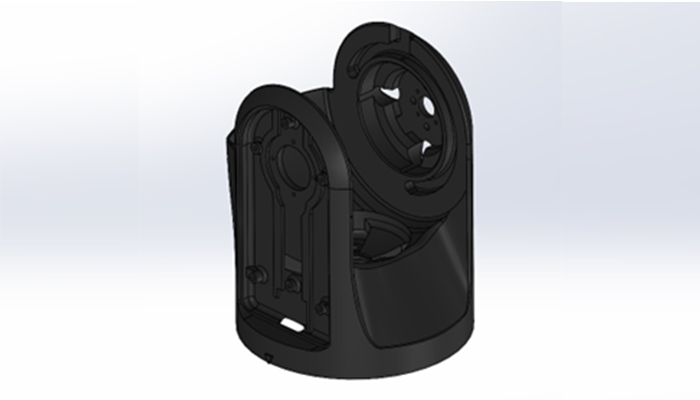

The body of the drone’s turret (photo credits: XYZprinting)

From FDM to SLS for Drones

TEKEVER’s goal was to evaluate the relevance of SLS in terms of surface quality and resistance. To do so, it decided to manufacture the turret body of its AR4 drone. This is a component with a very complex shape, with both thin and thick walls, small holes and rounded edges. The company first 3D printed it on an FDM machine, using ULTEM, a high-performance thermoplastic known for its high weight-to-strength ratio. One of the constraints of this process is the necessity of supports, which adds more material consumption and also impacts the final quality of the part. Since SLS does not require supports, it was a good alternative to FDM.

Beyond this constraint, it was also necessary to maintain the lightness of the part, to optimize the printing time and to have a water-resistant part. Three criteria that were met thanks to XYZprinting’s solution.

XYZprinting’s SLS Technology Meets Industry Constraints

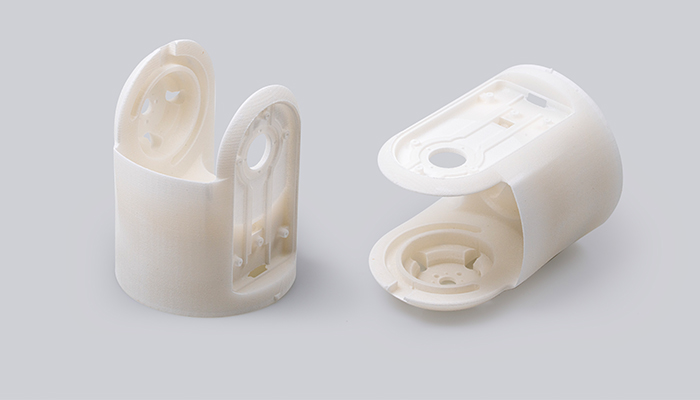

The AR4 UAV is an ideal solution for military and commercial applications that require rapid mobile deployment. Therefore, the system must be as light as possible to offer the best displacement. To minimize the weight of the component, it is therefore necessary to reduce the amount of material required and thus play with the filling of the part. In SLS, if the object has a closed geometry, evacuation holes must be added so that the unsintered powder can be evacuated from the inside. The company can either change the design of the part itself or use specific software to modify the filling geometry. In TEKEVER’s case, it added vent holes and hollowed out the part to reduce its weight.

In addition to the design of the part, it was also necessary to optimize the printing time of the part. The SLS process is ideal for this because it allows the different parts to be stacked on top of each other, so in a single print cycle, the company can obtain several components at once. The MfgPro230 xS 3D printer offers greater repeatability and a volume of 230 x 230 x 230 mm, allowing for multiple iterations. For comparison, a part on a FDM 3D printer would take about 16 hours to print, while on the MfgPro230 xS, it would take 10.5 hours. In contrast, to manufacture 4 components on an FDM machine, it is necessary to multiply the printing time by 4, that is to say 64 hours, while on the SLS machine, this could be done in only 18 hours and 15 minutes.

The final 3D printed parts (photo credits: XYZprinting)

Finally, the AR4 drone is a maritime surveillance solution that regularly passes over oceans and is exposed to high humidity levels. As a result, its components must be water resistant. The body of the turret must therefore be 3D printed with a material that has low water and moisture absorption. XYZprinting has developed a Nylon 12 that meets these requirements. The sPro12w is characterized by its good chemical resistance, low moisture absorption and excellent surface resolution. This led TEKEVER to choose it as the SLS material for the drone.

Satisfactory Results

The MfgPro230 xS printer has proven to be an ideal choice for manufacturing the AR4 UAV parts. Thanks to the volume of the machine and the material used, TEKEVER teams can optimize the printing time and produce better quality components. The company concludes, “The XYZprinting team gave a great customer support by helping us throughout the process of printing this part, from the adequate choice of material to the correct orientation for optimal results, clearing any doubts which might have risen.” If you want to know more about XYZprinting’s SLS 3D printer, click HERE.

What do you think of the use of SLS for the creation of drones? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.!