XYZprinting SLS Machines Are Compatible with High Performance PP and TPU

3D printing solutions manufacturer XYZprinting has announced a partnership with AM Polymers to offer two new materials for its selective laser sintering (SLS) machines. The range now includes an FDA-approved, food-grade PP01 polypropylene powder and a PB01 TPU powder for the footwear industry. This partnership allows XYZprinting to expand the capabilities of its industrial SLS 3D printers and broaden the scope of possibilities for its users.

SLS has become a very popular 3D printing process thanks to its ability to manufacture quality parts in series while optimizing costs and lead times. This is surely one of the reasons why XYZprinting has entered this niche, after already making a name for itself in the FDM 3D printer market. Since 2019, the manufacturer has indeed taken an industrial turn in the 3D printing market by developing SLS solutions which are more suitable for mass production. This time, it’s going one step further by offering qualified materials, developed by German manufacturer AM Polymers.

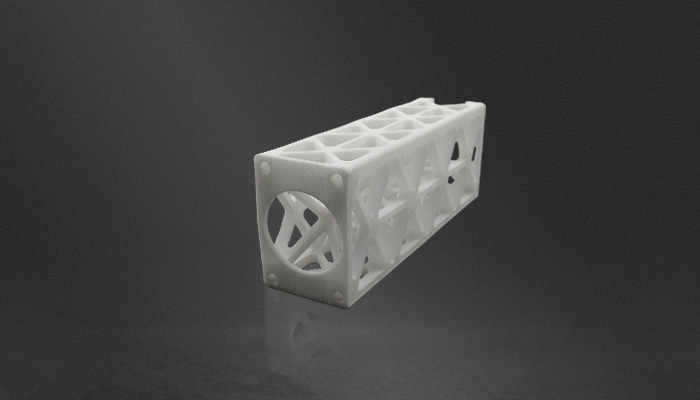

The powders are compatible with the SLS machines from XYZprinting (photo credits: XYZprinting)

An FDA Approved Polypropylene

AM Polymers’ PP01 polypropylene powder is now compatible with XYZprinting’s SLS machines. It is a material that offers a high level of detail, excellent chemical resistance at low density, a tensile strength of 20 MPa and an elongation at break of 30%. The powder is food contact compatible which will make it a material of choice in the production of parts used in kitchens and in the manufacture of packaging.

In addition, PP01 offers a 50% refresh rate and a very competitive price per kilo. Beyond food applications, this powder is ideal for the medical, automotive, robotics and education sectors. It can be used to create housings, ventilation systems or containers for liquids.

John Calhoun, Director of Sales North America, adds, “AM Polymers offers the highest performance materials available on the market; they are perfect for machines with an open materials strategy like the 230 and 236 from XYZ Printing. These are high performance, recyclable and easy to process powders, three key points for our professional users.”

3D printed parts with PP powder (photo credits: AM Polymers)

A High-Performance Elastomeric Powder

In addition to PP01 polypropylene, XYZprinting’s SLS machines are now compatible with AM Polymers’ PB01 TPU. This is a flexible material that offers high strength and excellent fatigue resistance. This high performance TPU also has a very good elongation and offers a 20% refresh rate. Its shore hardness is 75A, one of the lowest on the market.

The properties of this elastomeric powder make it an ideal choice for the creation of soles, sports equipment or shoe uppers. Its elasticity will allow the design of watertight seals for windows or cars but also clamps and other tooling parts on robotic machines.

Example of a 3D printed part with PB01 TPU (photo credits: AM Polymers)

Calhoun concludes, “Our SLS machines are available from $69,900. The combination of this affordable cost and the highest performing materials allows the customer to print quality parts for 1/5 of the price of our competitors.” To learn more about the capabilities of XYZprinting’s SLS machines, visit the manufacturer’s website HERE.

What do you think of the new powders from XYZprinting? Let us know in a comment below or on our Linkedin, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.