U.S. Navy to use Xerox’s newly-launched 3D printer, ElemX

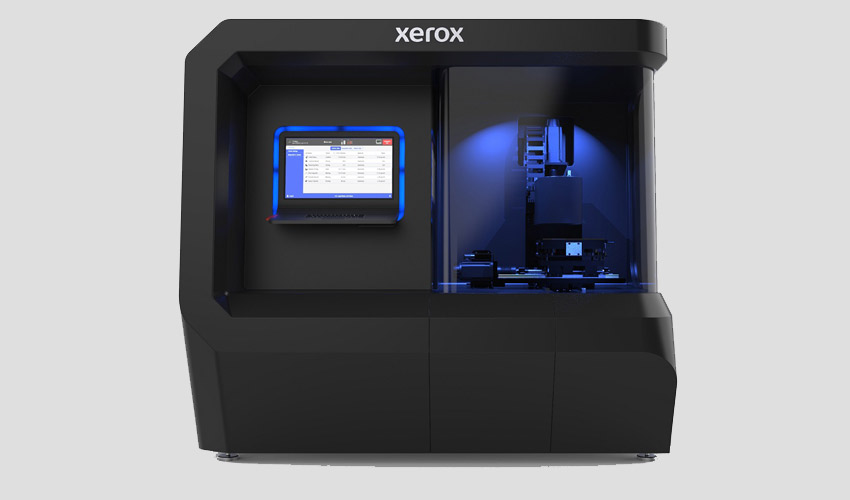

Last year, Xerox announced the acquisition of startup Vader Systems, which specializes in liquid metal additive manufacturing. It clearly stated the ambition to enter the 3D market, convinced of the technology’s potential. One year later, Xerox has introduced its first liquid metal 3D printer, ElemX. The machine uses metal, specifically aluminium, wires that are melted layer by layer to produce the final part. The manufacturer hopes to appeal to the aerospace, automotive, marine, and oil & gas industries. Already, the Naval Postgraduate School in California has commissioned a machine as part of a new collaborative research project into the applications for 3D printing for the U.S. Navy.

Currently the majority of metal additive manufacturing processes use powders to design more or less complex parts. These materials can represent a risk both for the user’s health and safety. The INRS had moreover published a complete report on the possible risks when handling metal powder. These include chemical risks, explosion and fire. Accordingly, Xerox placed their bets on a machine that relies on metal wire rather than powder. The company thus created the ElemX, measuring 2.7 meters wide by 2.1 meters high. The Naval Postgraduate School (NPS) in California were one of the first to receive the first ElemX as part as a collaborative research project into additive manufacturing with Xerox. The NPS will use the machine to research new capabilities for the Navy and Marine Corps.

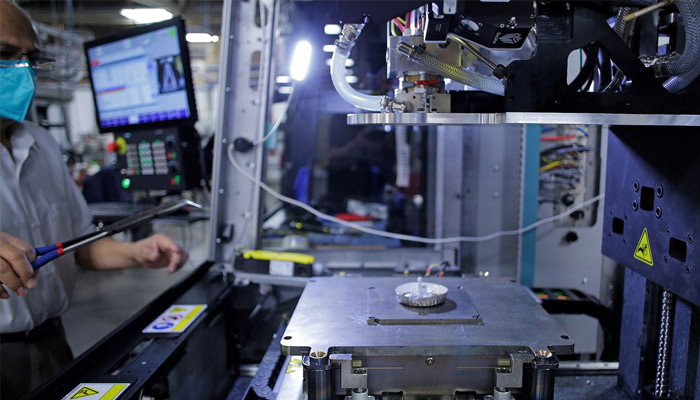

The ElemX’s build plate. (Photo Credit : Xerox)

The Xerox ElemX is based on a liquid 3D printing process

The Liquid Metal process is based on a metal wire, in this case aluminium: the coil is placed on the machine and the wire is fed into a tank which is heated to over 800°C. The metal is melted, forming droplets which are then projected onto the tray using a magnetic field. According to the manufacturer the machine is capable of depositing up to 1,000 drops per second. Therefore, the manufacturing process is faster than that of powder-based solutions and requires less post-treatment. The exact print volume of the machine is unknown, but it is thought that it can produce parts measuring up to approximately 300 x 300 x 127 mm.

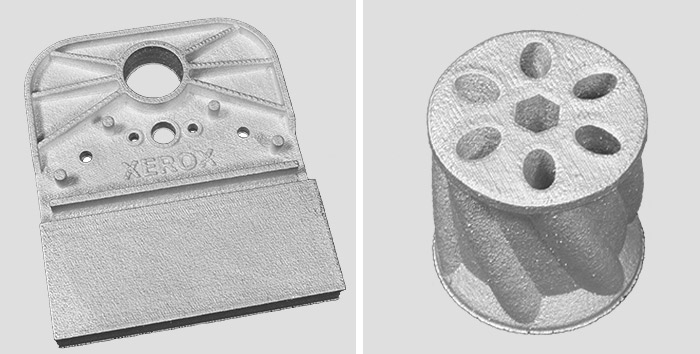

The Naval Postgraduate School (NPS) were the first to use the ElemX. As the name implies, the NPS is a graduate school for naval officers in the United States. It therefore chose to host the machine on its premises to explore its potential use for the design of spare parts for various ships and submarines, as well as tooling work. This research, particularly as it concerns liquid 3D printing processes, has the potential to dramatically transform the way the military supplies its forward-deployed forces. Tali Rosman, Xerox Vice President and General Manager for 3D Printing added: “Global supply chains leave industries like aerospace, automotive, heavy equipment, and oil and gas vulnerable to external risks. Our goal is to integrate localized 3D printing into their operations, and the real-time feedback from NPS gives us actionable data to continuously improve the ElemX.”

Parts printed with the ElemX (Photo Credit : Xerox)

For the NPS, the Xerox machine is interesting because aluminum is a metal that is resistant to corrosion and oxidation, a key necessity in a marine environment. Aluminium is also cost-effective and capable to withstand the rigors of operational demands. The NPS aren’t putting 3D printers on board ships quite yet, but the possibility is under study. The teams still need to conduct tests to ensure the technology is able to withstand things like vibrations and jolts- in short of all the constraints of a sea voyage. Ann Rondeau, retired Vice President of the NPS, concluded: “This collaborative research effort with Xerox and the use of their 3D printing innovations is a great example of how NPS uniquely prepares our military students to examine novel approaches to create, make, prototype and manufacture capability wherever they are. From the age of sail to the nuclear era, sailors have been fixing things at sea so they can complete the mission. This partnership is about the strategic ability of the Navy to have sailors on ships with the capability through creativity and technology to advance their operations at sea. Through collaboration, NPS and Xerox are helping build a Navy for the 21st Century.” Check out the video below to learn more about Xerox’s ElemX.

You can find out more about the ElemX and Xerox’s partnership with NPS here. What do you think about the Xerox ElemX? Is liquid 3D printing going to overtake powder-based processes as the method of choice for metal additive manufacturing? Let us know in a comment below or on our Facebook and Twitter pages! Sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox!