Wypro on Using 3D technologies to Develop Insoles

The use of 3D printing in medicine is opening the door to the development of new and innovative applications. The main advantage offered by this technology is the possibility of offering customized solutions that are adapted to each patient’s need. This is especially interesting in the field of orthopodology, where we are seeing an increasing implementation of additive manufacturing and 3D scanning for the development of unique orthopedic solutions insoles. One of the Spanish companies working in this area is Wypro. We interviewed its team to learn more the company and why they turned to 3D technologies.

3DN: Could you introduce yourself and tell us about your connection to 3D technologies?

I am Dr. Pablo Marín, podiatrist specialist in Biomechanics and CEO of Wypro. Together with Jorge Granell Mechanical Engineer specialist in 3D technology, I am also one of the co-founders of Wypro 3D Medical. In 2019 we formed a young multidisciplinary team consisting of 1 Mechanical Engineer, 1 Biomedical Engineer, 1 doctor, 2 podiatrists and 1 orthopedic technician, creating one of the first 3D design and printing units with own technology development, in the Orthopedics and Podiatry sector in Spain, located on the Costa del Sol.

Wypro was born the day that Jorge Granell, former skater of the Spanish national team, went to my office. During one of his periodic check-ups we saw the need to make orthopedic insoles with enough precision to absorb all the energy of the jumps and distribute the plantar pressures with a variable density and in such a small surface as the skate. Thanks to our passion for technology and research, we were able to recruit the whole team and the adventure began.

3DN: What is Wypro and how did the idea of creating the company come about?

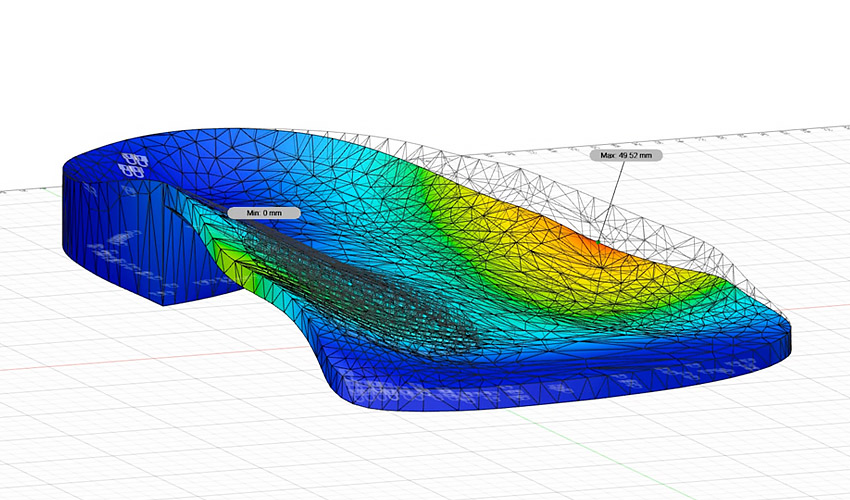

Wypro 3D Medical is a company from Malaga located in the field of Biomedicine and Engineering specialized in the design and manufacture of orthopedic insoles using 3D technology. For this purpose we develop our own design software based on Rhinoceros 3D and with automated elements using Grasshopper. One of the advances that we offer to the sector is the variable density point system based on the data offered by the platforms of plantar pressures, using finite element calculations and with only the colorimetry report offered by these platforms, our Script detects the color differences and applies a specific density according to the dynamic characteristics of the footprint of each user in an automated way. With this we achieve a specific elastic response for each user, having the capacity to apply specific protocols for athletes or pathologies, offering different response possibilities (for example, greater propulsion in specific phases of walking or greater dynamic range for sports such as paddle or athletics).

Wypro uses 3D technologies to manufacture orthopedic insoles

3DN: What is Wypro 3D Scan and what benefits does it offer?

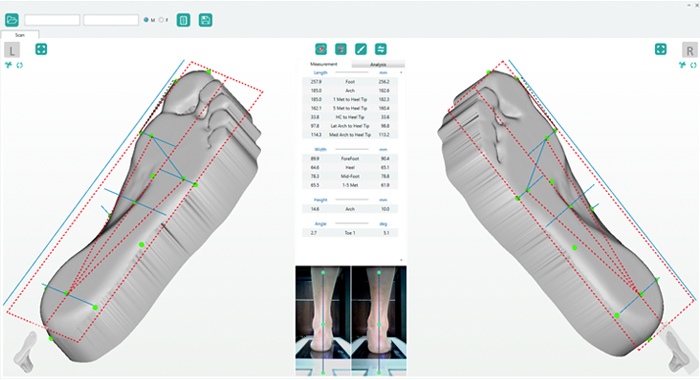

The Wypro 3D Scan is a 3D laser scanner for the podiatry and orthopedics sector that we developed in 2017. We were in a sector in which traditional methods were used with foams and plasters to obtain the measurements of the foot but these methods are more than 50 years old. Today, in less than 1.5 seconds, we can obtain a file with all the measurements and structures of the foot in the form of a mesh with 350,000 points, which automatically connects to our Cloud design platform and uploads the files from anywhere in the world.

The great benefits offered to professional users is that they can correct the foot and put it in a neutral position before scanning and in controlled load, this is a key factor, since it is not the same to take a mold of the foot with the weight of the body (more similar to reality) than without it. Subsequently, the engineering team can modify the scan by design, since many feet, for example, in the case of rigid flat feet, it is difficult to perform the plantar arch correction technique due to the collapsed anatomy of the foot. With traditional techniques we would have to spend hours of work to rectify the positive plaster cast by polishing and by eye. And what would happen if the cast is lost or the patient needs after a few years an exact copy of the treatment? With our solution we can offer exact replicas to customers all over the world.

To customize the templates use your Wypro 3D Scan

Currently, we are in the implementation phase with some pilot customers, of our new scanning App for IOs and Android, in which we take advantage of the new Lidar sensors from Apple along with the videogrammetry for the rest of mobiles and devices. With the camera of any mobile device we can scan the feet of patients.

3DN: What 3D printing method do you use for insole development?

After testing several 3D printing technologies, we finally opted for Selective Laser Sintering (SLS), in this printing method we have found the perfect balance between printing speed and accuracy. Being able to 100% solid parts to address mechanical stresses of the foot (weight, deformation and fatigue) was one of the fundamental conditions for the choice.

By means of a low power laser the material is sintered obtaining pieces very similar to those obtained by injection molding with a very good surface finish. We are currently working with PA12 as our main material, which offers the perfect balance between the flexibility required by the user to make the insoles comfortable and the rigidity necessary for a good correction of the biomechanics of the foot.

3DN: How do you see the future of 3D printing in this field?

3D printing as in other fields has been one of the most revolutionary advances in recent years, it has managed to reduce the delivery times of the insoles and in combination with custom software design of plantar orthotics is achieved a micron adaptation to the user’s foot. In recent years thanks to open source printers and new developments in various materials, 3D printing at industrial level has begun to democratize for startups and small companies could not invest large capital in the acquisition of this type of machinery for rapid prototyping and short series.

Thanks to foot scanning, customized insoles can be designed

Wypro is currently in a research and development phase differentiated in several lines. On the one hand, the development of new specific materials for the manufacture of orthopedic insoles, in collaboration with a multinational, we are developing a resin with mechanical properties between polypropylene and TPU. On the other hand, we are starting to implement automations through machine learning to make treatment predictions and biomechanical insole designs based on the disorders presented by the patient and the order form sent by the professional, managing to reduce design time and improve delivery times, a crucial factor for medical treatments.

The biomechanical insoles have evolved a lot in recent years, the adaptation periods are minimal and the quality of life of our patients improves exponentially with the use of Wypro 3D Medical insoles, applying design technology using finite elements, laser sintering and prediction systems. Achieving very short adaptation periods and being able to adapt to any footwear.

3D printing technology has many little known applications such as the design of treatments for podiatry, however, we have not done anything more than uncover the tip of the iceberg. We can continue to exploit this versatile and effective technology for production and prototyping in different areas and continue to improve people’s quality of life.

3DN: Any last words for our readers?

We are a multidisciplinary and young team, we welcome new partnerships with companies and incorporation of new talents to the team. If you feel that we can collaborate or we can help you, do not hesitate to consult our website, here.

What do you think of Wypro and its use of 3D technologies? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: Wypro