#Working3D: Six Questions for a 3D Printing Biomedical Engineer

Today we bring you a new installment of #Working3D, the series of articles in which we give insight into the different jobs available in the additive manufacturing industry. Specifically, we will go into detail on a position in one of the sectors in which 3D printing plays a key role: the medical sector. According to a report by Global Market Insights, the 3D printing market in the healthcare sector is expected to reach a value of $19.5 billion by 2032. This growth is due, in part, to increased private and public investments in research and development (R&D) activities. And in this new installment we will understand the day-to-day life of an expert in additive manufacturing working in the industry. We interviewed María Álvarez, a biomedical engineer and quality manager at SIMIM3D, to learn a little more about her professional work and her relationship with 3D technologies.

3DN: Could you introduce yourself?

María Álvarez Caballero, biomedical engineer.

My name is María Álvarez Caballero. I graduated with a degree in Biomedical Engineering, with specialization in medical devices, biomaterials and biomechanics, from the Polytechnic University of Madrid (UPM) in 2016. Then, I completed a Master’s Degree in Biomedical Engineering, with specialization in advanced implant design techniques and tissue engineering, from the Polytechnic University of Valencia (UPV) in 2017. Currently, I am a biomedical engineer and quality manager at the Simulation and 3D Printing Platform (SIMIM3D) of the Health Area of La Coruña.

3DN: How did you discover additive manufacturing?

My experience in the working world began at the Hospital Universitario y Politécnico La Fe in Valencia, where I started working as a biomedical engineer in the Clinical Simulation and Patient Safety Area. Basically, I was dedicated to facilitating, technologically and logistically, the recreation of certain situations and environments so that healthcare professionals could experience the representation of real clinical care events, for different purposes: practicing, learning, evaluating, experimenting, etc.

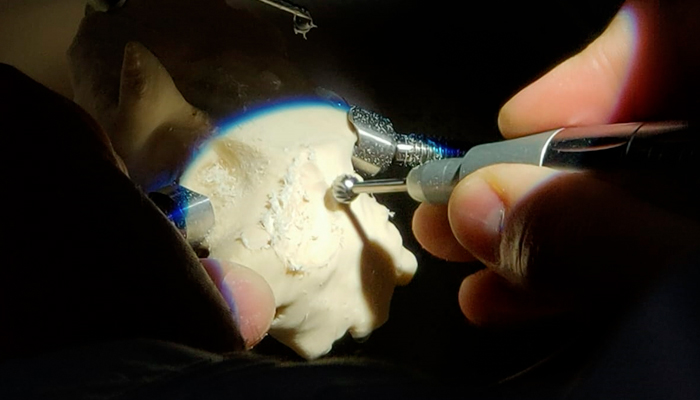

This is how I came into contact with 3D printing, a technology with great potential to support deliberate practice in healthcare; both through the design, development and manufacture of simulators. That is, devices that replicate the essential characteristics of a task (anatomical, physiological, haptic…), as well as through the production of props and simulation elements that increase the fidelity of the environment by increasing the degree to which the environment of a simulation reproduces reality, its appearance and functionality. The possibility of further exploring the multiple clinical applications of this technology is what brought me to SIMIM3D.

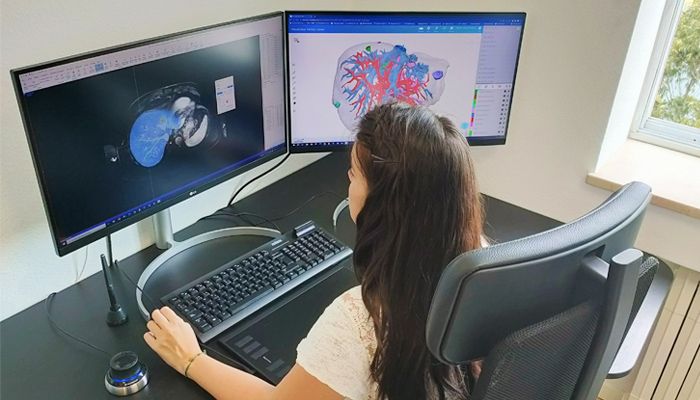

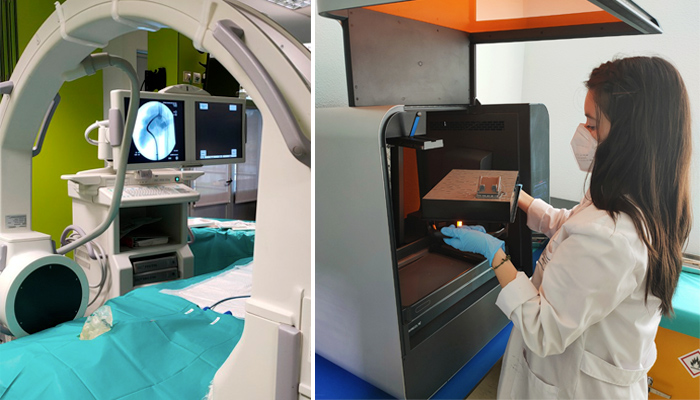

María Álvarez is currently working on the 3D Simulation and Printing Platform, SIMIM3D

3DN: What is your current role at SIMMIM3D? What is a typical day like for you?

Currently, I combine functions as a biomedical engineer and quality manager, which allows me to work on both technical aspects and system management. Fundamentally, we work with medical image processing, 3D scanning, CAD design, FFF and SLA. In addition to the educational applications mentioned above, we also develop research support services: prototyping new medical devices as well as means to facilitate experimental surgery and microsurgery; illustrating scientific publications; validating new techniques and medical devices (MPS). And, fundamentally, we develop tailor-made and in-house PS for healthcare purposes, which can intervene in the decision-making process of diagnosis and treatment, as in the case of digital and printed anatomical models, or which can intervene directly in the treatment, such as surgical cutting guides.

As I mentioned, I combine the daily tasks of design, development, documentation and management of new products and services with the maintenance, monitoring and improvement of the quality management system (QMS). This has to be in order to ensure good production practices, seek user satisfaction and guarantee the benefit and safety of patients. Since SIMIM3D is a central service, completely transversal, of the Healthcare Area, the continuous improvement of the QMS also implies the hospital integration at all levels in the hospital systems and procedures.

3DN: What are the required qualifications to be a biomedical engineer?

3D technologies are synonymous with versatility and multi-disciplinarity. On a technical level, you can work in several areas, as is my case, or you can specialize and dedicate yourself more exclusively to medical image segmentation, digital design and/or 3D printing. In any case, healthcare knowledge is also crucial to ensure the adequacy of the services offered.

Training in medical image segmentation, digital design and 3D printing is key

From the Ethical-Legal Working Group of the 3D(BIO)PRINTING HUB of the ISCIII Biobanks and Biomodels Platform, of which I am the coordinator, we analyze that, at national level, the most common profile in this type of work is engineering, highlighting biomedical and industrial engineers. However, there is also a high percentage of clinical profiles, especially in hospital environments, among which radiologists and surgeons stand out, as well as printing, radiology or simulation technicians. In the end, what is essential is to be curious about this type of technology and its potential applications and to find a way to specialize in it.

If, in addition, you work as a PS manufacturer, it is essential to have a basic knowledge of QMS, regulations and application standards, which will need to be further developed depending on your job responsibilities.

3DN: What are the biggest challenges in your position?

The implementation of 3D units in hospitals has a relatively short history and, as is often the case in any field, innovation and technological development are usually ahead of the regulation and integration of this innovation into everyday systems. For this reason, I believe that one of the greatest challenges at present would be to complete the successful hospital integration of the service on which we have been working for several years and to continue to raise awareness among healthcare personnel in order to comply with the good practices and documentary requirements demanded by the current regulatory framework.

Photo Credits: SIMIM3D

3DN: What advice would you give to someone who wants to work as a biomedical engineer in the 3D printing industry?

I believe that curiosity, willingness to learn, continuous improvement of both one’s own skills and the object of work and being open to constant challenges are key aspects for a biomedical engineer to add value to a hospital 3D unit. And the same goes for any professional with a different basic training but who also wants to work in this field. In the end, non-technical skills are important and decisive for a project to prosper.

What do you think of the role of a biomedical engineer working with 3D printing? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.