#Working3D: Six Questions for a Prosthodontist Using 3D Printing

Once again, it is time for our #Working3D series, where we take a closer look at different professions in the additive manufacturing sector. This time, we wanted to focus on a position that relates to dental 3D printing. This sector was estimated to be worth $3.1B in 2023 with strong growth projected for the coming years, showing clearly that dentistry is a core application for 3D printing. But in such a large industry, it can be hard to know what jobs are available. That is why we decided to speak to Dr. Wendy Clark. A prosthodontist by trade and part of the faculty at the University of North Carolina – Chapel Hill, Dr. Clark also regularly uses 3D printing as part of her work. We sat down with her to learn more about the position, necessary qualifications and what her day-to-day work looks like.

3DN: Could you introduce yourself?

My name is Wendy Clark. I am a prosthodontist, which is a dental specialty that focuses on tooth replacement and complex restoration. I am also an expert in using 3D technologies in this field.

Dr. Wendy Clark

3DN: How did you discover additive manufacturing?

I became interested in additive manufacturing when it was being introduced in dentistry. The possibilities of improving patient outcomes as well as access to care were apparent, and I wanted to be a part of that progress. This interest in digital dentistry continues to this day.

As a clinician and educator, 3D printing has changed every facet of my career. I have been working with digital denture workflows in my clinical practice for many years, but the FDA clearance of printed dental resins and the development of the higher impact printed resins has really changed the game. With 3D printed denture workflows, I’m able to expedite patient care with in-office printing and have been able to provide work with service clinics that would not have been possible with conventional techniques.

Dr. Clark holding a full 3D printed denture

3DN: What is your current role? What is a typical day like for you?

I am full-time faculty at the University of North Carolina Adams School of Dentistry. My time is spent mostly teaching dental students in the classroom and clinic, focusing on both foundational and digital dentistry. I spend a portion of my time working on research projects with students and residents, mostly surrounding digital dental workflows and materials. I also treat patients one day a week in our dental faculty practice

In 2020, the pandemic changed the way we were teaching at the dental school. My colleagues and I were able to scan and 3D print tools that were not available due to the supply chain. We used CAD software and 3D printing to teach in ways that we had never been able to before.

Since then, I have seen such a curious and innovative mindset from many of my students. We have gotten to beta test CAD teaching software, do in vitro materials research on new printed dental resins, and just explore together. Their energy is palpable, and I feel really fortunate to be able to work with them in this way using 3D technology.

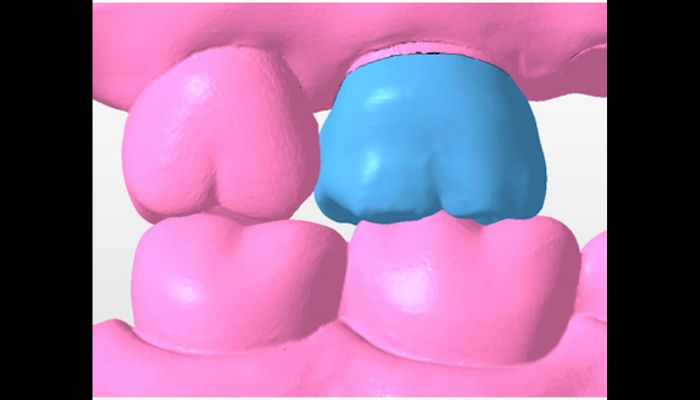

A design file for 3D printed crowns made by Dr. Clark’s students

3DN: What qualifications and experience are required for someone in your position?

I completed a 3-year prosthodontics residency program after dental school. There are many other entry points into digital dentistry, though, including dental laboratory technology and dental assisting.

3DN: What are the biggest challenges you face in as a prosthodontist?

As an educator and clinician, we rely a lot on “evidence based dentistry” to ensure we are providing the highest quality care for our patients. Often, by the time an additively manufactured dental material has been tested and published in a peer reviewed journal, it has been replaced by another material or is obsolete. This makes it hard to stay “ahead of the curve.”

3DN: What advice would you give someone hoping to work as a prosthodontist or in digital dentistry?

Find a printer to play with! What we consider dental printers and dental resins can be expensive – when I wanted to learn and understand the workflows, I found a low-cost hobby printer with inexpensive resin options that made the learning curve less intimidating.

A design for a partial denture

What do you think of the work of a prosthodontist using 3D printing? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: Dr. Wendy Clark