Researchers mimic wood’s ultrastructure with 3D printing

At Chalmers University of Technology in Sweden, a team of researchers announced they succeeded in 3D printing parts using a wood-based ink, perfectly imitating the ultrastructure of the natural material. This is good news for the industry, which wants to be more environmentally friendly and is therefore developing a lot of hybrid additive manufacturing materials. This development could make it possible to produce greener products, directly derived from trees.

This is not the first time that we have presented a project that combines 3D printing and plant materials, let alone wood. Canadian scientists had 3D printed electronic circuits from nanocellulose, a material directly extracted from wood pulp. It’s true that this material is interesting in terms of porosity, strength and torsional resistance. The problem often lies in its transformation because, unlike plastic, it cannot be easily melted down. It is therefore generally necessary to saw or plane it, which generally leads to the destruction of its ultrastructure, thus losing its unique properties. However, thanks to additive manufacturing, Swedish researchers seem to have found a solution to preserve its interesting properties.

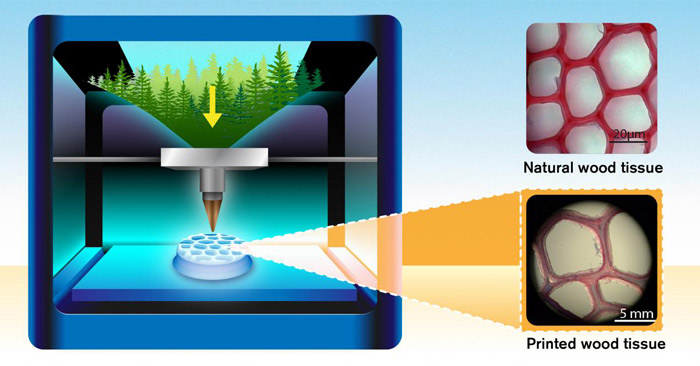

Researchers imitate the natural cellular architecture of wood | Photo Credits: Yen Strandqvist/Chalmers University of Technology

Imitating the ultrastructure of wood to preserve its properties

The team reportedly converted wood pulp into a gel containing nanocellulose to which it added hemicellulose that acts as a sticking agent. This gel served as the basis for them to design a 3D printable ink. It is not so much the development of the material itself that is interesting, but rather the interpretation and digitization of the genetic code of the wood: researchers can thus guide the 3D printer to manage the orientation and shape of cellulose nanofibres, understand the properties of the wood and reproduce its ultrastructure very precisely. This allows them to reproduce parts with the same characteristics as the plant material.

Professor Paul Gatenholm, Director of Research, continues: “This is a breakthrough in manufacturing technology. It allows us to move beyond the limits of nature, to create new sustainable, green products. It means that those products which today are already forest-based can now be 3D printed, in a much shorter time. And the metals and plastics currently used in 3D printing can be replaced with a renewable, sustainable alternative.”

This new manufacturing method will inevitably have an impact on traditional production processes. Wood-based products are numerous in the industry and thanks to additive manufacturing they can be custom designed while reducing manufacturing times. We can therefore imagine a rather large number of applications.

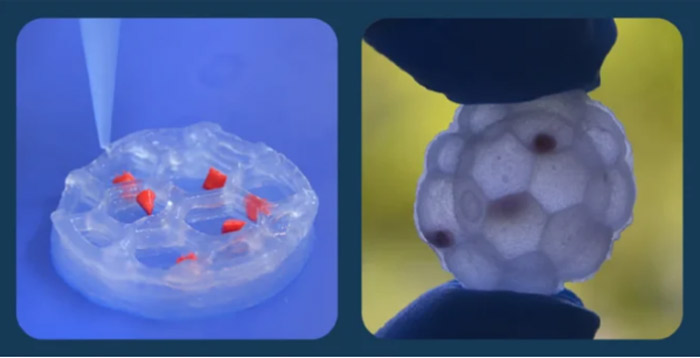

This manufacturing technique could make it possible to create greener packaging

The researchers have already developed a prototype for an innovative packaging concept. They printed honeycomb structures, with chambers between the printed walls, and then managed to encapsulate solid cellulose particles inside these chambers. It is known for its oxygen barrier properties, which means that it could be a promising method for creating airtight packaging for food or pharmaceutical products, for example.

Paul adds: “Manufacturing products in this way could lead to huge savings in terms of resources and harmful emissions. Imagine, for example, if we could start printing packaging locally. It would mean an alternative to today’s industries, with heavy reliance on plastics and C02-generating transport. Packaging could be designed and manufactured to order without any waste.” An innovation that we will follow closely! In the meantime, find more information about the project HERE.

What do you think of this new research? Tell us what you think in a comment below or on our Facebook and Twitter pages! Don’t forget to sign up for our free weekly Newsletter, with all the latest news in 3D printing delivered straight to your inbox!