Wisconsin Researchers Transform Dairy Waste for 3D Printing

Two professors at the University of Wisconsin-Platteville have unveiled a new breakthrough that combines agriculture with additive manufacturing. The researchers have developed a new technique to turn spoiled milk into an eco-friendly 3D printing material. The method was recently patented and uses milk proteins such as casein and whey to create new sustainable filaments for 3D printing. This would help reduce plastic waste and open new revenue streams for American dairy farmers.

The project first began as a response to the dairy industry’s excess milk production during the COVID-19 pandemic. Supply chain disruptions led to the widespread dumping of milk, resulting in significant profit losses for farmers. However, instead of letting the surplus go to waste, Dr. John Obielodan and Dr. Joseph Wu saw an opportunity to use the milk’s proteins. They first focused on extracting the proteins from spoiled milk and incorporated them with polymer blends that are used in 3D printing. After years of experimentation, the team successfully produced a biocomposite material that is both strong and flexible in high-performance applications.

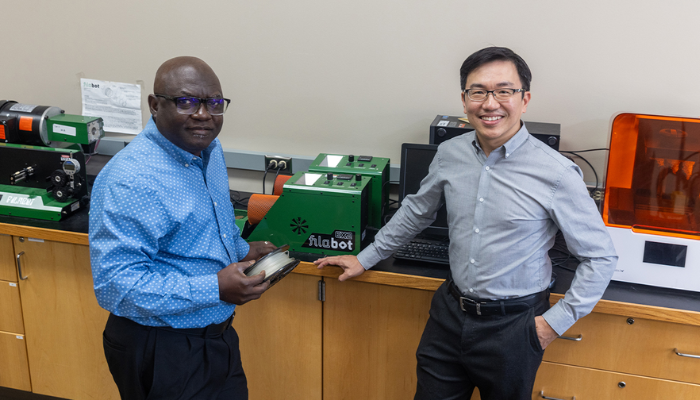

Dr. John Obielodan (left) and Dr. Joseph Wu (right) stand in their lab after announcing the new patented material. (Photo Credit: University of Wisconsin-Platteville)

The research itself focused on testing which proteins performed best in combination with existing 3D printing materials. Students from the university’s chemistry and mechanical engineering departments also took part in purifying the proteins and adjusting formulations to help optimize the strength and printability of the material. The result was a unique polymer that performs well and is also biodegradable. This would provide an alternative to petroleum-based plastics that currently dominate the industry.

According to the USDA National Agricultural Statistics Service, over 56.7 billion pounds of milk are produced in the United States. (Photo Credit: University of Wisconsin-Platteville)

In looking towards the future, this technology has potential applications beyond 3D printing filaments. Early research suggests this research could be used to produce other types of sustainable plastic products, from automotive components to consumer goods. By merging additive manufacturing and the dairy industry, this project showcases how unexpected connections can often lead to impactful innovation.

This type of research also serves as a reminder that the future of 3D printing materials may not come only from high-tech labs but also from farms and local industries across the United States. In Wisconsin, a glass of milk could very well be just as likely to end up as a phone case or perhaps a machine part as it is on a breakfast table.

What are your thoughts on this recent development? Would you ever try a 3D printed product made from milk? Let us know in a comment below or on our LinkedIn or Facebook pages! Plus, don’t forget to sign up for our free weekly Newsletter to get the latest 3D printing news straight to your inbox. You can also find all our videos on our YouTube channel.

*Cover Photo Credit: Reuters