Why Low-Volume Production is Driving Innovative Applications for IN3DTEC

Against the backdrop of a slowing global economy, low-volume and customized production have become key strategies for companies to reduce development risks and quickly validate markets. 3D printing technology plays a central role in this process, leveraging its advantages of being mold-free, highly flexible, and low-cost. However, bridging the “last mile” from prototype to true mass application still requires overcoming multiple challenges, including precision, appearance, lead time, and cost control.

This is where IN3DTEC comes in: with 11 years of technical experience and having supported more than 15,000 customers worldwide, it offers a range of manufacturing processes to meet the needs of both mass production and low-volume production. It has expertise in metal 3D printing, metal casting, and high-performance polymer processing. This enables it to cover a very wide range of applications and to leverage the advantages of different manufacturing processes. But why call on IN3DTEC’s expertise?

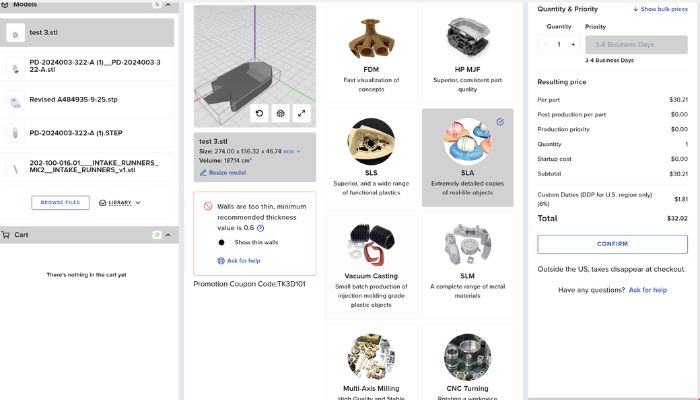

IN3DTEC’s online quotation system

Smart Quoting and Order System: A Head Start

When you get started in 3D printing, it is not always easy to know which process to choose, which material to use, etc. That is why the IN3DTEC platform features an AI-based online quotation system. This allows you to compare the costs and performance of several additive manufacturing processes, including SLS, SLA, MJF, ceramic printing, and FDM. It is combined with an online order management system, allowing users to manage the entire ordering process.

±0.02mm Precision: Achieving Production-Grade Standards

In addition to maintaining control over their project, they can also rely on a quality control system to meet all their requirements, particularly in sectors such as aerospace and medical. Specifically, IN3DTEC uses DFM analysis, thermal flow simulation, and print simulation to guarantee the best results. As a result, combined with its 5 Axis CNC machining process, its metal prints can achieve tolerances of up to 0.02 mm! The platform also supports more than ten metals, including stainless steel, aluminum alloy, titanium, and Inconel.

Proven Manufacturing Methods

IN3DTEC has developed an entire manufacturing system that is not solely based on 3D printing. The platform offers sand 3D printing & metal casting, vacuum casting, and injection molding. These techniques, combined with additive manufacturing, reduce development cycles, enable low-volume production runs of up to 500 parts, and lower costs.

The company also offers a post-processing service to meet the performance requirements of certain finished parts—for example, flame retardancy, wear resistance, and waterproofing. It therefore offers surface treatment solutions for metal parts—anodizing, polishing, plating, ceramic coating, etc.—as well as for plastic components, such as vaporfuse smoothing, sanding, and painting.

4.8/5 Rated, Fast Manufacturing and On Time Delivery

This comprehensive manufacturing system is appealing to many users because they can count on very short delivery times—IN3DTEC guarantees delivery in just two days in 98% of cases. This is due, in particular, to the 400 pieces of industrial equipment that it has invested in, but also to its expertise. One of its customers, Neuhaus, an American bicycle manufacturer, told us: “Through IN3DTEC’s metal 3D printing, we produced a lightweight bracket that would be difficult to achieve with traditional CNC,” said Daniel Yang, a design engineer from Neuhaus in the U.S. “This component achieved a 46% reduction in weight and lowered the cost from $30 to $10, enabling us to efficiently customize high-performance bicycle frames in different sizes.”

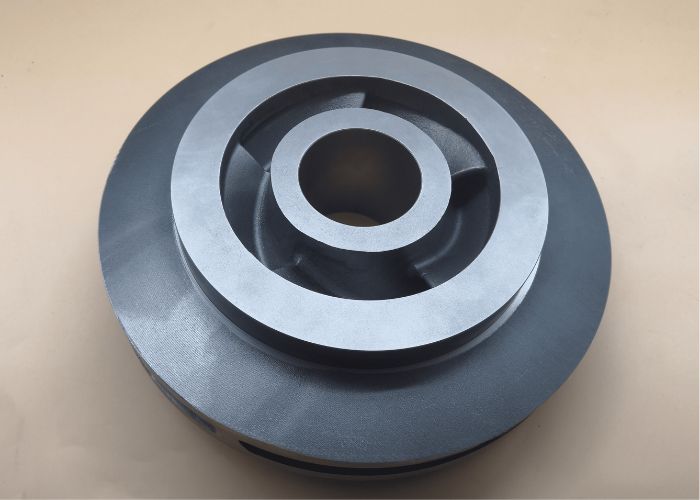

The 3D printed bracket

From smart quoting and precision manufacturing to rapid delivery, IN3DTEC has bridged the path from prototype to mass production through technological integration and closed-loop services. As demonstrated with Neuhaus, its value lies not only in reducing costs and lead times but also in providing a one-stop solution for flexible manufacturing and product innovation. In the evolving trend of customized manufacturing, IN3DTEC is becoming a vital bridge connecting design and mass production. To learn more about IN3DTEC, visit its website HERE.

What do you think of IN3DTEC? Let us know in a comment below or on our LinkedIn or Facebook pages! Plus, don’t forget to sign up for our free weekly Newsletter to get the latest 3D printing news straight to your inbox. You can also find all our videos on our YouTube channel.

*All Photo Credits: IN3DTEC