Why HP AM Is Making Local Manufacturing a Strategic Priority

The manufacturing industry has changed its rules: it’s not a question of relocating production and finding the cheapest possible labor anymore, but rather of finding a faster and more agile local model. In recent years, due to the pandemic and the geopolitical context, we have seen how necessary it is to create a more responsive and adaptable workflow. This is where additive manufacturing becomes a key tool: it speeds up development cycles and time to market without compromising product performance and quality. HP Additive Manufacturing Solutions (HP AM) has been championing this approach, proving that AM can deliver speed and reliability at scale.

While its Multi Jet Fusion technology continues to prove itself, HP AM has officially entered the filament market with a high-temperature industrial machine that meets demanding requirements. At Formnext 2025, HP AM unveiled this solution, along with new materials and partnerships that reinforce the idea of local manufacturing sovereignty. The goal is clear: make AM accessible across industries and empower engineers and creators to design better, wherever they are.

3D printed piece with the HP 3D HR PA 11 Gen2 material

Accelerating the Adoption of Additive Manufacturing through Materials

To achieve this, HP AM is focused on reducing the total cost of ownership. The company is currently lowering the cost per part by up to 20%, especially through advanced materials development. The HP 3D HR PA 11 Gen2 material is now available, offering up to 80% powder reusability and up to 40% reduction in variable part costs. This material achieves the lowest carbon footprint of any MJF material to date and reduces the total cost of ownership for high-volume production.

In metals, HP AM is enhancing its Metal Jet technology with new material qualifications and alloy innovations. For example, the OptiPowder Ni718 has just been certified by Continuum Powders and INDO-MIM Inc. for use with the HP Metal Jet S100 machine. This powder offers a density greater than 98% after sintering, consistent hardness, and low carbon content. This enables it to be used in highly demanding environments such as energy, defense, and aerospace.

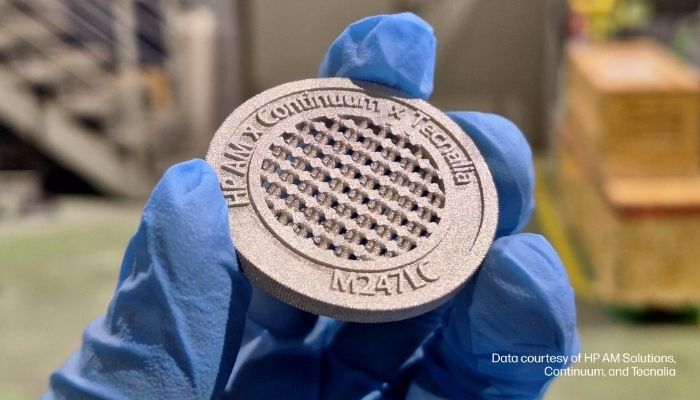

And HP AM isn’t stopping there. It has announced the development of OptiPowder M247LC, in collaboration with TECNALIA and Continuum Powders. This low-carbon, nickel-based superalloy offers resistance to high temperatures and corrosion, making it ideal for aerospace and energy applications.

Metal 3D printed part with the OptiPowder M247LC

Key Partnerships

By expanding material options and reducing the total cost of ownership, HP AM is accelerating additive manufacturing adoption, and through strategic partnerships, it’s building a fully integrated ecosystem that redefines the future of production. One key example is the collaboration with Würth Additive Group. The two companies have joined forces to integrate HP’s manufacturing solutions with Würth’s Digital Inventory Services and global logistics network. This integration allows manufacturers to transition from having a physical inventory to on-demand spare parts management, wherever they are located.

This collaboration guarantees that parts can be available and validated in real time, instead of having users wait weeks for spares and wonder where they are coming from. Furthermore, workflows are fully secure on HP printers, and users can count on a more agile and sustainable value chain.

The integration allows manufacturers to transition from having a physical inventory to on-demand spare parts management

Ultimately, HP’s aim is to build an end-to-end solution that will promote local, on-demand production in a rapidly changing global context. Alex Moñino, Vice President and General Manager of HP Additive Manufacturing Solutions, sums up:

“What sets us apart is that we are not just selling machines, we are delivering end-to-end solutions for agile, on-demand production at scale. Our Multi Jet Fusion technology is built for speed, quality, and consistency, but our unique strength lies in seamless integration with design tools, a global support ecosystem, and the ability to help customers think beyond just part printing. From advanced material science to digital workflows and production-grade repeatability, HP AM is redefining what’s possible.”

One thing is clear: HP AM made a strong impression at Formnext 2025, showing its commitment to delivering more than a machine. The company’s objective is to offer a complete workflow that integrates seamlessly into users’ manufacturing and design processes, enabling maximum agility: something HP now calls a “competitive mandate.”

Interested in learning more about HP AM’s solutions? Click HERE!

What do you think of HP’s strategy to prioritize local manufacturing? Let us know in a comment below or on our LinkedIn and Facebook pages. Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Image Credit: HP Additive Manufacturing Solutions

Seeing HP investment in local manufacturing last year was effective. AM makes supply chains resilient without global logistics constraints.