What Were the Most Innovative 3D Startups in 2023?

Additive manufacturing is constantly evolving in all fields. Indeed, just this year, we have seen exciting developments in metal 3D printing, bioprinting and multi-material printing, as well as interesting concepts for greater sustainability. But that’s not all! As you may know, each month in 2023, we interviewed a new innovative startup that impressed us with their approach and use of 3D printing. Now, it’s time to choose the best startup of the year, and for that we need your voice! You have until January 2nd, 2024 at 12PM ET/6PM CEST to vote and choose the winner out of our candidates for the 3D startups of the year in 2023. The results will be announced on 3Dnatives on January 4th!

POOLP

The first 3D startup to start 2023 was French company POOLP, which was created by two ENPC (École Nationale de Ponts et Chaussées) students who wanted to expand the potential of additive manufacturing in art and architecture. After experimenting with a multitude of recycled and bio-based materials, they developed their own solution to make them compatible with 3D printing. Thus arose the so-called urban microfactory, a production tool capable of valorizing local plastic waste and transforming it into material for additive manufacturing. The 3D printing system uses large-format FGM (Fused Granulate Modeling) technology, which uses plastic pellets instead of filaments to create all kinds of three-dimensional parts. With this manufacturing system, the POOLP team seeks to promote the circular economy, an alternative philosophy of production and consumption. You can find more information about this startup in the interview we conducted with its team.

The manufacturing solution developed by the startup (photo credits: POOLP)

Spherecube

Born from a Università Politecnica delle Marche project, Spherecube is an innovative startup working to make 3D printing of composites more sustainable. The laser thermal curing system, developed by its team, is able to create high-performance composite products automatically, and without geometric constraints. Specifically, Spherecube’s technology is based on the extrusion of two raw materials in different physical states. On the one hand, there is the thermosetting polymer matrix (in a viscous fluid state) and, on the other, the reinforcement material (in the form of fibers). In this way, the printhead has been designed to efficiently mix the matrix and the reinforcement, so that there is perfect adhesion of both during the manufacturing process. With this technology, the startup is targeting industries such as aerospace, biomedical, sports and marine. Learn more about Spherecube in this 3D startup interview from 2023.

Photo Credits: SphereCube

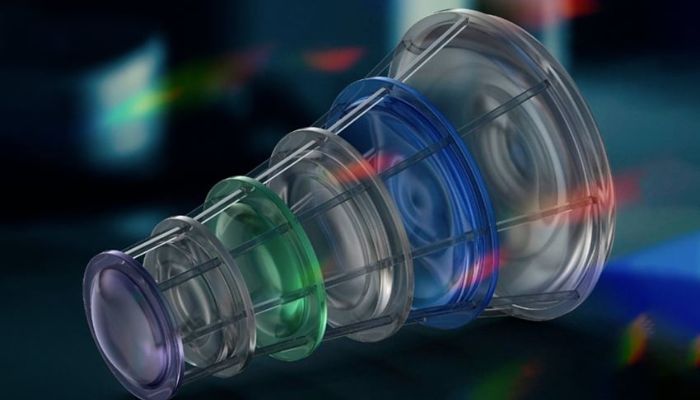

Axtra3D

In the field of resin 3D printing, two technologies stand out: SLA and DLP. The former is precise but slow, while the latter is much faster, but with great limitations in surface quality. The American startup Axtra3D has come up with a solution to this problem. The HPS (Hybrid PhotoSynthesis) technology developed by the company combines both methods to guarantee high resolution of parts in a much faster process than stereolithography. Specifically, its machines integrate a projector (DLP) and laser (SLA) simultaneously in a true coaxial system. Thus, this additive manufacturing method is ideal for applications in a wide variety of industries, including automotive, aerospace, prototyping, healthcare and dentistry, among others. Read more about HPS technology and the company’s upcoming plans HERE.

Photo Credits: Axtra3D

Diabatix

The Belgian startup Diabatix was created with the aim of helping companies with the design of their products to obtain proper cooling. To this end, it has developed ColdStream, a cloud-based platform that enables the use of generative design tools to provide better cooling of 3D printed parts. From thermal analysis to thermal design, the platform is based on state-of-the-art simulation methods without the need for additional software or hardware. In addition, something very interesting about the solution developed by Diabatix is that it adapts to the manufacturing method to be used later. That is, before starting the design process, the user will select the manufacturing technique of his preference, and the software will automatically optimize the design within the limits of the chosen technique. To learn more about the company and the ColdStream platform, read the full interview.

Photo Credits: Diabatix

Gastronology

Dysphagia is a medical condition that causes difficulty swallowing in many patients. This causes the body to need more time and effort to move food or liquids from the mouth to the stomach. In order to make swallowing easier for those with this condition, Dutch company Gastronology has turned to 3D food printing. Specifically, it has developed an additive manufacturing solution that allows food to be presented in its original form, made from fresh puree, with its natural smell and designed with its original shape. Gastronology’s products can also be found frozen and packaged. This requires a five-step process: puree production, food 3D printing, shock freezing, packaging, and frozen storage. Thanks to this technology, the company manages to transform meals into a moment of pleasure, replacing the tasteless and mixed options that currently exist for patients with this condition. You can find out more about about this 2023 3D startup HERE.

3D printed cauliflower (photo credits: Gastronology)

3D Spark

The adoption of software for workflow management in additive manufacturing is a growing trend in the industry. One of the companies developing such solutions is another of our 3D startups for 2023, 3D Spark. Based in Hamburg, the startup emerges with the goal of helping companies find ways to cut costs and lead times while reducing CO2 emissions in production. In turn, Spark 3D’s platform ensures that they can benefit from an automatic evaluation of 3D printed parts and identify the optimal development process for their products. The latter is done by comparing 3D printing with a wide variety of manufacturing processes, providing a transparent and independent basis for manufacturing decisions. As a result, industrial companies will be able to opt for more efficient, sustainable and crisis-resistant production. You can learn more about 3D Spark’s software and its benefit to the manufacturing industry in the interview with its team HERE.

Créditos: 3D Spark

ONEBra

Italian startup ONEBra is highlighting a problem that affects many women: those who have undergone a mastectomy often suffer from asymmetry of their breasts. ONEBra is counteracting this with customized 3D printed cups. Through this, the 3D startup aims to help women improve their self-image and quality of life. The process is simple as well. On the website, a 3D breast scan can be created by following simple video instructions. The ONEBra team then uses this scan to create a custom bra cup. The team uses a combination of MJF and FDM technology. The cup, made from TPU/TPE, is coated with a material suitable for skin contact and shipped directly to the customer. 3D printing enables ONEBra to manufacture customized cups with as little waste as possible and with high precision. ONEBra also wants to offer cups for sports bras and swimsuits. For more information about this innovative 3D startup of 2023, ONEBra, read the full interview HERE.

Photo Credits: OneBra

HETEROMERGE

Another of our 3D startups for 2023, HETEROMERGE, emerged from the University of Dresden with the goal of creating a multi-material manufacturing head for more efficient micro 3D printing. During their research work, the HETEROMERGE team faced several challenges in micro- and nano-scale 3D printing. First, there are more limitations in this sub-millimeter range and, more importantly, it was difficult to process multiple materials by leveraging 2PP technology. The patented multi-material head is designed to counteract this problem by enabling perfect realignment after an automated material change. This technology opens up interesting fields of application in micro-optics, photonics, in medical device development as well as in tissue engineering and bioprinting. Find out more about HETEROMERGE in this interview.

Photo Credits: Heteromerge

Carcinotech

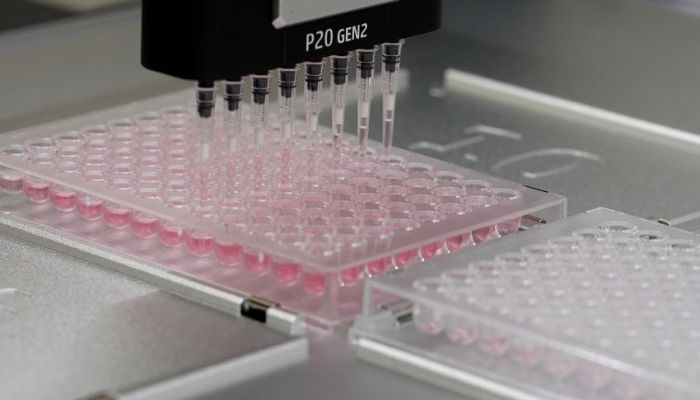

Founded in 2018, Carcinotech was one of the most prominent 3D startups in 2023. It specializes in making tumors using 3D printing for cancer research. The team uses 3D bioprinting to create living tumors from biopsies, primary cells, immune cells and cancer stem cells from patients. After fabrication, the tumors grow and are ready for drug testing within a week. This enables fast, accurate and ethical drug screening, as results are available 14 days after the test. With its approach, Carcinotech aims to give millions of cancer patients access to innovative therapies. It is the only company using 3D printing to produce live tumors in order to obtain representative and meaningful data. Carcinotech’s founder shared a lot of interesting information with us in an extensive interview, which you can find HERE.

Photo Credits: Carcinotech

Balena

Balena addresses one of the fashion industry’s biggest problems: extending the useful life of products. Around 60% of today’s clothing is made of plastic, which is rarely recycled and ends up in the trash. To create sustainable fashion for the future, the Israeli company is developing compostable and biodegradable thermoplastic materials for this industry. The BioCir material can be used for injection molding or 3D printing and recycled at the end of its useful life. In this way, Balena aims to create a circular model for consumer goods, which is what led us to name them one of our innovative 3D startups from 2023. Want to know more about the company? Read the full interview HERE.

Créditos: Balena

BIO INX

The 3D printing of organs, muscles and tissues are the major goals of the medicine of the future. Bioprinting involves not only science but also industry. Currently, the main challenges lie in standardization, regulations and different material requirements. Each printing technology requires a different material in order to process it efficiently. The Belgian startup BIO INX has specialized in the development of bioinks for the various 3D bioprinting technologies. These inks are designed to mimic natural tissue as closely as possible without having to resort to animal testing. BIO INX wants to actively shape the field of biofabrication and contribute to the research of 3D printed tissues and organs. Find out more about BIO INX’s motivations and approaches in this interview.

Photo Credits: BIO INX

Craft Health

Craft Health, a Singapore-based pharmaceutical startup, wants to tackle the problem of polypharmacy and is counting on 3D printing as an ally. Polypharmacy, i.e. taking too many drugs, often leads to interactions and, therefore, discomfort for patients. Thanks to 3D printing, Craft Health can combine several active ingredients in a single tablet and thus create a customized medication. It is also possible to influence the dosage, shape, color and taste. Drug release can be immediate, sustained or delayed. Craft Health hopes its approach will help people take their medication and open up new treatment options. As part of our up-and-coming 3D startups of 2023, you can also read their full interview HERE.

Photo Credits: Craft Health

What do you think of the outstanding 3D startups throughout 2023? Let us know in a comment below or on our Linkedin, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

What Was the Most Innovative 3D Startup of 2023?

Voting has now closed. The winner will be announced on January 4th!

N/A

Innovative 3D bioprinting for cancer research using stem cells

There’s no such thing and that cannot be done.

HETEROMERGE