What Were the 3D Printing Trends in 2023?

As 2023 comes to a close, it is once again time to reflect upon the 3D printing trends that have dominated since January. In general, this year was a turbulent and exciting one, not just in additive manufacturing but around the entire world. Though escalating conflicts and general global economic difficulties have been prevalent, with a significant negative impact on much of the world, there have been positives as well.

The rise of artificial intelligence (AI) in particular has been huge. Starting with the launch of ChatGPT at the end of last year, AI has been the term on everyone’s lips, with numerous (ever increasingly advanced) solutions being launched over the course of 2023. Of course, though the prospect of ever more mature AI was a welcome one to many, it also prompted discussions into the proper use of it, for example when it came to art and writing. Moreover, AI also was a subject in 3D printing.

Could this be the future of 3D printing with AI? Probably not, but the topic has been a popular one in 2023 (photo credits: inTinker)

It should be noted that AI and machine learning have been used for quite some time already in additive manufacturing. However, the use of these software focused mostly on process control during printing and automation. This year we also saw a discussion into new ways that AI could be used in 3D printing. For example, AI software could help to design 3D models.

That being said, though AI may have dominated everywhere else, it seemed there were even larger trends present in the AM industry this year. From a market in turmoil to changing needs for technologies to an increasing focus on applications, check out what we considered to be the biggest trends in 3D printing in 2023.

Uncertainty in the 3D Printing Market in 2023

Of course, not everything was rosy for the additive manufacturing market in 2023. As mentioned above, this year we saw a considerable amount of turmoil worldwide. This can be related to a number of factors including the continuing war in Ukraine, new global conflicts, increasing gas prices, inflation and economic downturns in many different countries. The tech market in general was especially badly hit, with layoffs continuing throughout the year and poor performance on the stock market. This also impacted the 3D printing sector.

Starting last year and continuing through 2023, many of major 3D printing companies announced layoffs including a second round of firings from Desktop Metal in February, Essentium letting go 16–30 workers in August and finally Markforged cutting 10% of its workforce after a poor Q3 showing due to a $5 million decline from the previous year and with cash, cash equivalents, and short-term investments declining by $10 million at the end of the second quarter 2023.

But layoffs have not been the only sign of turmoil on the market. Notably, we can point to the saga of Desktop Metal, Stratasys and Nano Dimension. It began in March 2023, when Nano Dimension announced that it would launch a formal bid to acquire fellow Israeli company Stratasys. Though Stratasys seemed uninterested in the proposition, the back and forth continued between the companies, with the backdrop as well of Nano Dimension’s own internal turmoil as conflict brewed between the executive board and shareholders, for many months. This was punctuated by the announcement of Desktop Metal and Stratasys that they would merge. This was then later further complicated by 3D Systems throwing its hat in the ring to acquire Stratasys.

Stratasys was at the heart of a significant amount of activity in 2023 (photo credits: Eyal Izhar/Stratasys)

It came to an end finally in September, after Nano Dimension had pulled its offer, when the merger between Stratasys and Desktop Metal ultimately fell through. Thus ending the drama that had dominated most of the year but leaving many in AM disquieted. Stratasys also withdrew from talks with 3D Systems, noting that the offer undervalued the company and that they had concerns about the management structure of the combined company.

But what was underlying this turmoil in 3D printing in 2023? Well, it seems to be closely related to general global economic uneasiness, as the companies most affected were those trading on the stock market. You may remember a couple of years ago when SPAC mergers were all the rage in additive manufacturing, showing the increasing flourishing of the field. While we cannot say that was negative, it is undeniable that we are currently seeing backlash now for many of the companies that went public in 2021 and 2022. Though they are not the only ones affected as shown by the recent bankruptcy announcement by SmileDirectClub.

This could also be seen through noncompliance notices sent by the New York Stock Exchange to both Desktop Metal and Markforged due to not meeting the minimum average closing price ($1.00) over a consecutive 30-day period. In particular, Markforged seems to be seeking alternatives as it seeks to avoid delisting on the NYSE as the latest noncompliance notice in November 2023 is their second.

In a recent press release regarding the notice, the company stated, “The Company intends to notify the NYSE within 10 business days of its intent to regain compliance with Rule 802.01C. The Company can regain compliance at any time within the six-month cure period if, on the last trading day of any calendar month during the cure period, the common stock has a closing share price of at least $1.00 and an average closing share price of at least $1.00 over the 30 trading-day period ending on the last trading day of that month. The Company fully intends to remain listed on the NYSE, and will consider the best available alternatives, including, but not limited to, a reverse stock split, subject to stockholder approval, if necessary to regain compliance.” Although this also may be behind the recent controversial post on social media from the founder of the company Gregory Mark who, despite no longer being associated with the company, called for Formlabs to merge with or acquire the company.

Still, it needs to be said that downturns are normal in any sector. Though there has been much discussion within the 3D printing community on what these signs mean for the industry, you cannot take the negative without also acknowledging the positive. For example, at Formnext this year, we saw growth in both exhibitors and visitors, showing the continual and strong interest in additive manufacturing among both companies and laymen. There also have still been promising mergers and acquisitions: the acquisition of HAGE3D by BigRep for example which shows the importance of high-temperature 3D printing as well in AM. Additionally, as we will see in the other 3D printing trends in 2023, hardships have also led to forward-thinking and innovation throughout the industry.

Markforged has been issued two noncompliance notices from the NYSE (photo credits: Zach Rosenzweig/Markforged)

Applications Take the Spotlight

For the past few years, much of the 3D printing market has been focused on the processes themselves, showing what they are and why they are important. But this year, we have seen a turn. Rather than working on ever more different 3D printing technologies, there has been an increased focus on how exactly 3D printing can be used. That is to say, on the concrete applications for the technologies.

This has shown itself in a variety of ways. Number one is that one or two years ago discussions started to turn away from the use of 3D printing prototyping or tools as the focus was put more on its use for end-use parts. And of course, there is quite a lot of truth to this.

Indeed, over the past few years the many applications for end-use parts made using additive manufacturing have skyrocketed, including even critical safety parts such as those used in the aerospace or oil & gas sectors. Nevertheless, it would be disingenuous to say that end-use parts were the only application for 3D printing. One notable sign of this change has been an increased focus on the use of 3D printing for prototyping and molding, as we saw at Formnext this year.

This has been seen in reports as well. In Jabil’s survey of additive manufacturing decision-makers, released in July 2023, the use case which showed the most growth since 2021 was in prototyping: with 97% of users saying they were currently using 3D printing for that purpose, compared to 72% in 2021. Although repairs, end-use parts and jigs, fixtures, and tooling also all saw growth from previous years.

The report notes that, “Prototyping continues to be a central application of 3D printing in organizations, with its usage growing rapidly since the previous survey. Additionally, there has been a significant increase in the number of companies employing additive manufacturing for production parts since 2017. Concurrently, the use of jigs, fixtures, and tooling has nearly doubled.”

The use of 3D printing for hybrid technologies has also been in the spotlight in 2023. Both 3D Systems and Massivit released user cases this year showing the benefits of 3D printed molds as a way to cut time and costs for users. For 3D Systems this paired well especially with its acquisition of Titan Additive last year, as seen by their case study with Duo Forms for the creation of thermoforming molds. David Rheinheimer, Duo Form Product Development Manager, explained, “We have gained a lot of business with our EXT 1270 Titan Pellet 3D printer. The turnaround time for parts, molds, and formed parts has put us leaps and bounds above our competition.”

Companies like Massivit and 3D Systems have showcased user cases for 3D printed molds this year (photo credits: Massivit)

Medical 3D printing has also seemingly grown leaps and bounds this year as point of care medicine is increasingly becoming a reality. Indeed, the importance of 3D printing in healthcare is not a secret as the technologies allow for more customizable healthcare. But this year there have been many advancements in the sector including in bioprinting, prosthetics and more. Indeed, even the Wohlers Report 2023, released back in April, identified healthcare as one of the major applications for AM.

In any case, regardless of what exactly the applications are, it is undeniable that concrete uses of 3D technologies are the focus of more companies this year. A trend likely to grow in 2024 as the market will likely start to recover from some of this year’s turbulence. What remains to be seen however whether that will signal even more new applications, or a return to trusty, if less flashy, favorites.

Changing 3D Printing Needs for Users in 2023

Though this increased focus on applications does not mean we have not seen advancement in 3D technologies this year. We have seen changes as companies have clearly been responding to certain new trends among users. A phenomenon that has arisen as 3D printing needs have started changing. This is seen most clearly in terms of affordability, speed and changes due to industrialization.

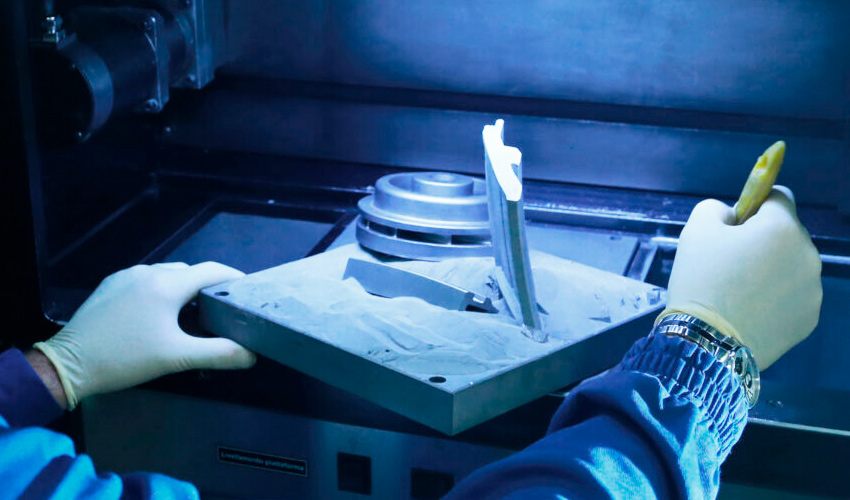

Let’s look at affordability first. Before when companies wanted to turn to lower-cost 3D printers, extrusion or vat photopolymerization solutions were their only possibility. However, with the ever-continual industrialization of the market as well as more and more companies turning to more advanced AM technologies, we have also seen a corresponding decrease in price. This is most notably the case for SLS 3D printing.

Selective laser sintering is popular for its high-production capabilities as well as study parts. But, due to its use of a laser, solutions tend to be higher priced, even if they still are less than those using DMLS or other metal powder bed fusion solutions. Yet, thanks to advancements in the process and more companies offering their own solutions, we have started seeing more affordable solutions using SLS. Allowing for industrial-level production at a much lower cost.

In 2023, one trend has been the increasingly affordable industrial 3D printing solutions available on the market, including those using SLS (photo credits: Sinterit)

Although this is not the first time we have seen this, the Formlabs Fuse 1 or the Sintratec kit come to mind, this year we have seen a number of SLS solutions under $50,000. Which, while still expensive, is significantly less than the $100,000+ solutions that we started with. And SLS is not the only technology where this is clear, we can point also to the rise of binder jetting.

Last year we told you about the increased binder jetting solutions on the market and in 2023 their prevalence was clear. Binder jetting continues to be a popular technology for both ceramic and metal 3D printing and in many cases costs less than other processes compatible with the materials. This intersection shows that even as the market continues to industrialize and ramp up production, affordability remains key with speed as well gaining in importance.

Though classic example of course of affordability and speed has to be Bambu Lab. Though the company only officially launched last year, it has taken the 3D printing world by storm. The secret to Bambu Lab’s success is a straightforward one as well: the company has enabled high-speed, multi-material FDM printing at a fraction of the cost of many of its competitors on the market. Can it really come as a surprise that its solutions are being hailed by many makers as the “future” of FDM 3D printing? Especially now with the launch of the company’s first bedslinger, the A1, earlier this year, which is even more affordable than the company’s first printers, the P1P and P1S.

The company’s rise to success has only been solidified in 2023 as well as it seems to seek to follow the path set by others. It is going to be interesting to see how Bambu Lab continues to take market shares to bigger and historical players like UltiMaker and Raise3D and see how they will respond. Especially considering the backlash the company has already faced. For example, earlier this year when numerous Bambu Lab printers randomly turned on overnight and started printing, a significant security concern for many. Still, it is undeniable that the company has latched onto a heretofore unmet need in the community, showing again the changing tastes of users in 3D printing.

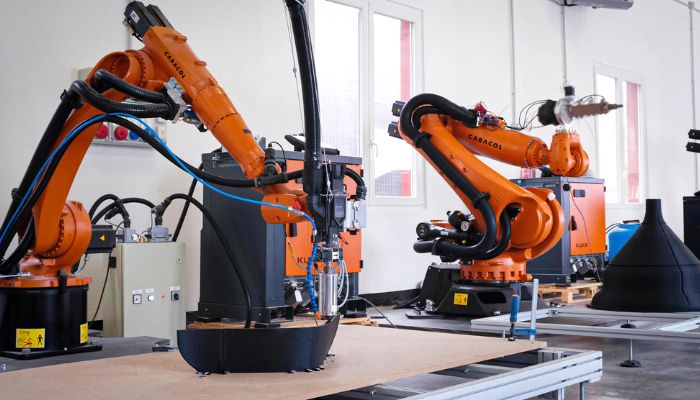

Still affordability is not all we have seen. Additive manufacturing has only continued its move towards further industrialization in 2023, seen as well through the rise of hybrid manufacturing (discussed as well in the applications section), pellet 3D printers and of course robotic arms. Pellets in particular seem to be having their time to shine as major players including Roboze and 3D Systems join long-term mainstays in the market like Pollen AM, WASP and Re3D. Pellets are popular as the material costs less, especially since plastic pellets are widely available in industry in general.

Robotic arm 3D printing certainly seems to be one trend that is here to stay beyond 2023 (photo credits: Caracol)

With this rise of pellets too, we have seen the popularity of robotic arms as well. Though originally considered niche within AM, this year many more companies are offering robotic arms as well as interchangeable heads to offer even more flexibility in creating metal and plastic parts (or even wool as we saw recently!). The reason for this is simple as well, once again it goes back to affordability. While many robotic arm solutions can be a little DIY as they must be built, they can be made compatible with any number of different materials and AM processes (FGM and DED come to mind) for a much cheaper price than other solutions on the market. This is another one that we can only expect to grow in the coming years.

And that wraps up our 3D printing trends for 2023. From a turbulent market to an increased focus on applications and changing 3D printing processes, this year was one to remember in additive manufacturing. As we go into 2024, it will be especially interesting to see how AI and robotics can be combined to increase productivity in AM; hopefully increasing productivity even more in verticals like automotive and aerospace.

What do you think of our 3D printing trends in 2023? What do you predict will be the trends dominating the AM market in 2024? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.