What Were the 3D Printing Trends in 2022?

As 2022 comes to an end, it’s time once again to reflect upon the state of the 3D printing market this year. Or more specifically, it is the moment to look back at the trends that dominated the additive manufacturing industry. And what was certainly clear this year is that the AM sector is continuing the progress that it has already made in previous years. For example, it has continued to recover from the pandemic as well as continue to industrialize, moving especially towards both large-format 3D printing and larger-scale operations. Additionally, actors in the field continue to focus on sustainability.

The connection between sustainability and 3D printing especially is certainly not a secret. AM is often lauded as a much more environmentally friendly process thanks to its ability to reduce waste. And though it is not perfect, with plastic use in particular courting controversy, the focus on developing the technologies more and encouraging environmental responsibility with 3D printing has only grown. In particular, we can point to the fact that the Additive Manufacturing Green Trade Association (AMGTA) continues to expand, counting many leaders in additive manufacturing among its members. Currently, the association has 50 member companies, a sharp increase from the beginning of 2021.

Sherri Monroe is the Executive Director of the AMGTA, an association which has grown rapidly as interest in 3D printing’s role in more sustainable manufacturing is explored (photo credits: 3Dnatives)

That being said, we also saw a number of new trends dominating the sector. But what exactly are these trends? How have we changed from previous years? Where do we see AM in the near future? To close out the year, we took a step back to reflect on the key takeaways from the 3D printing sector in 2022.

Consolidation Takes the Center Stage for 3D Printing in 2022

At the beginning of the year, we took a look at a report that suggested that the 3D printing industry was not likely to consolidate in the near future. However, that was quickly proven wrong. Despite great expansion in the industry in 2022, we also saw many signs of consolidation in the 3D printing sector, through acquisitions and mergers of course but also through partnerships.

Perhaps one of the biggest consolidation shocks of the year was the merger between Ultimaker and Makerbot back in May 2022. For those who have been acquainted with 3D printing for quite some time, you might remember that MakerBot was one of the first desktop 3D printer companies to emerge from the RepRap movement and was actually acquired first by Stratasys in 2013. Meanwhile, Ultimaker is well known on the market not just for its desktop solutions but also its Cura software, one of the most well-known slicers among 3D printing enthusiasts.

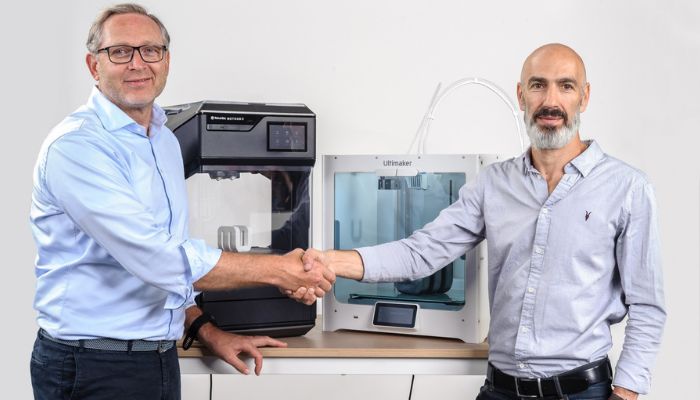

Nadav Goshen (left) and Juergen von Hollen (right) shaking hands on the closing of the merger (photo credits: Ultimaker)

The merger was closed in September of this year, launching a new brand under the name UltiMaker. The companies have both stressed that for them the merger was key to “fueling global 3D printing innovation”, namely by combining their current strengths and solutions as well as investing in new R&D for more products. Nadav Goshen, the former CEO at Makerbot and now CEO of the new combined company, commented in a press release, “As we begin the next chapter together as UltiMaker, we will continue to focus on developing 3D printing innovations to advance the availability of accessible and easy-to-use 3D printing solutions. By combining our teams and technical expertise, we can work towards developing and delivering a comprehensive portfolio of products to support professional, educational and light-industrial applications.”

But that is not the only example. The year started off strong in February when 3D Systems announced that after a year of selling various parts of the company in 2021, it would be acquiring Titan Robotics and Kumovis, thus returning to the FDM market after a lengthy absence. In August, the company also sought to acquire dp polar GmbH, a German designer and manufacturing of an AM system that has been optimized for high-speed mass production of customized components.

Similarly in August, Stratasys, one of the leading and first 3D printing manufacturers, announced its acquisition of Covestro’s 3D printing material business. Carbon also made its first acquisition of ParaMatters, a software company known for its generative design software capabilities. And at this point, you may be sensing a pattern within many of these acquisitions and mergers throughout the years. Namely that we saw that AM companies are seeming to seek to create full end-to-end solutions for additive manufacturing by targeting companies that may have different strengths, for example materials or software.

With its acquisition of Digital Metal, Markforged will move into the metal binder jetting market (photo credits: Digital Metal)

This can also been seen as more companies sought to gain access to other AM technologies to extend their own reach. A notable example is Markforged which is seeking to enter the metal binder jetting market with its acquisition of Digital Metal. Markforged, which is best-known for its carbon-fiber and metal 3D printing processes, has been growing rapidly. And the move into metal binder jetting shows its continued intent to grow as well as placing it as a direct competitor on the American market to powerhouse Desktop Metal.

Furthermore, it is not just AM companies that are moving forward with acquisitions and mergers. This year we have also seen large tech companies who were not as active in the sector acquiring 3D printing companies. For example, globally-known camera-manufacturer Nikon moved to acquire SLM solutions through a Public Takeover Offer, announced in September. As of the expiry of the acceptance period for the offer, Nikon has officially acquired about 92.38% of SLM. In a similar vein, the struggling Fast Radius, which went public this year but then quickly saw a decrease in performance, was acquired by SyBridge Technologies in a $15.9 million sale process under the US bankruptcy code.

However, consolidation does not just refer to acquisitions, though those were also clearly abundant in 2022. As part of this trend, we also want to highlight the increasing role of partnerships in additive manufacturing. Notably between software, post-processing and 3D printer manufacturers as a way to provide customers with a “one stop shop” for their 3D printing needs, helping in the continued industrialization of AM.

The importance of software is clear when you look at many of the acquisitions of partnerships in the AM sector over the course of 2022 (photo credits: 3Dnatives)

Discussing for example the cooperation between AMT and HP, wherein automation and software partnerships are keys to developing a fully comprehensive solution for customers, Wayne Davey, Global Head of Sales and Go To Market for HP’s Personalization and 3D printing business, commented, “We are excited to take our partnership to the next level with AMT given their shared vision, shared customer, and proven portfolio of post processing post processing technology. At HP we believe leveraging partnerships that bring unique expertise to the end-to-end Multi Jet Fusion workflow are key to accelerating the scale of additive manufacturing to production.”

Moreover, DyeMansion, an established provider of post-processing solutions, and Nexa3D have entered a partnership for the same reason. Kevin McAlea, Chief Operating Officer, Nexa3D, explained “It’s only natural that we would partner with DyeMansion, a leading provider of automated post-processing solutions for powder bed fusion, to ensure that our industrial customers can leverage high-throughput manufacturing capabilities from end-to-end as well as reduce their total cost of operation.” In any case, it seems that many in the 3D printing industry are seeing that we are stronger together, making consolidation a growing reality.

Disruption on the Market Despite Growth

Still, where you see consolidation and growth, disruption is often not far behind. From the very beginning of 2022, disruption was a key trend in the market for a variety of reasons. One of the very first was of course the war in Ukraine. The Russian Invasion officially started on February 24th, 2022 after months of increasing aggression by the Russian government. The move built upon years of tensions between the nations since the annexation of Crimea in 2014.

And though this may seem far from 3D printing, the additive manufacturing community as a whole certainly reacted to the news. In the immediate aftermath of the invasion, many well-known faces in the industry moved to denounce the attack. Beyond that, a number of 3D printing companies including EOS, decided to stop business with Russian customers while others organized donations.

Though we heard about this crisis mostly at the beginning of the year, support continued throughout. We can point notably to silent auctions launched by the Together We Are Strong initiative which was founded by companies such as Nexa3D, EOS, BigRep, Wohlers Associates powered by ASTM International, SYGNIS, Digital University, and 3YOURMIND. These took place at major 3D printing events including Rapid + TCT 2022 and Formnext.

Companies like Poland-based Sygnis (whose 3D printing farm is pictured here) used 3D printing to help the war effort (photo credits: Sygnis)

There were other ways that the 3D printing community supported the Ukrainian people as well. Users from across the globe as well as companies worked to make 3D printed parts that could help Ukrainians. One notable example is the creation of open-source tourniquet files that could be used on injured civilians. Additionally, companies like Unlimited Tomorrow and Oxford Performance Materials are seeking to send 3D printed prosthetics to the war-torn country. Ukrainian organizations devoted to using additive manufacturing to help their country also rose up including 3D Printing for Ukraine. In this case, the disruption happened outside of the AM community which then rose to meet it. But this was not always the case.

For example, supply chain disruptions were also a source of concern over 2022. And though of course 3D printing is often one of the solutions to this issues, best exemplified during the beginning of the COVID crisis, plastic and microchip shortages the world over managed to affect nearly every industry. This was also exacerbated by the Ukrainian War itself as trade routes were rewritten almost overnight and crucial materials were not able to get where they needed.

Last but not least, though we have seen significant growth in the AM sector over the past few years or so, not all the signs have been so rosy. One of the most worrying signs of course has been a number of layoffs over the course of the year. Though this is likely at least partially a result of the ongoing consolidation of the market as mentioned earlier, it is also clearly a sign of an ongoing trend in the tech sector in general due to the current global recession. And it affected many of the largest companies in the industry. Desktop Metal, Nexa3D, Xerox and Carbon all announced that they were letting go of significant portions of their workforce, with DM alone reducing its global workforce by 12%.

Discussing the reduction, which was named a cost optimization measure, Ric Fulop, CEO of Desktop Metal, noted, “As outlined on prior financial results calls, we have been focused on identifying opportunities to optimize our expense structure while maintaining our growth opportunities. We believe this initiative, which builds on steps we began to take in the second half of 2021 to integrate our teams, positions Desktop Metal to meet our near- and long-term financial commitments and supports our path to profitability.” Showing that for many in the industry, profits may have been less desirable than expected.

Automation and Software Gain in Importance for 3D Printing in 2022

It may come as no surprise that on this list of 3D printing trends from 2022, we are including automation. As 3D printing continues to industrialize, the need to automate the different steps is becoming increasingly important to allow for the type of large-scale printing that is desired in a number of industries. As such, over the course of this year we saw a number of different technologies and software that arose to meet that need.

We already touched upon it when we discussed consolidation, but one sign of the increased importance of this was in partnerships between 3D printing solution manufacturers and software providers. Indeed, one of the places where it was most evident was in post-processing. Though perhaps less discussed than other additive manufacturing steps, post-processing, or the treatment of a part after printing, is critical for the production of high-quality parts. However the step remains time-consuming and difficult, as also shown in PostProcess’s latest report on trends in post-processing. Automation could help solve that and that is where the industry seems to be moving, as can be seen with the recent partnerships between AMT and HP, as well as DyeMansion and Nexa3D.

But post-processing is not the only area where we have seen a focus on automation in AM. Software is increasingly important in the field as monitoring becomes a key requirement for the creation of end-use parts. As a result, many have been investing more in either creating their own proprietary software solutions to allow for a complete end-to-end AM workflow or through partnerships with software providers allowing for greater automation overall.

Once again we must mention Markforged as the company has steadily developed The Digital Forge Platform, a smart platform designed for their solutions. This year Markforged enabled the integration of simulation software in The Digital Forge. Shai Terem, president and CEO of Markforged especially understands the need for the further integration into 3D printing operations, stating: “Simulation enables our customers to adopt The Digital Forge deeper into their manufacturing operations by replacing more mission-critical tooling and end-use metal parts with validated and optimized 3D printed advanced composite parts with Continuous Fiber Reinforcement. Cloud-based software innovation like Simulation is core to our mission to bring industrial part production to the point of need.” This shows especially the importance that automation and software has when it comes to scaling production.

AI has also continued to solidify its foothold within the 3D printing as a whole especially when it comes to automation. More and more companies are adopting machine learning or AI-based software to help improve processes like monitoring. But it is also being used by researchers as a way of improving productivity in AM.

One notable example is a recent collaboration between Fraunhofer Research Institution for Additive Manufacturing Technologies (IAPT), the Fraunhofer Institute for Ceramic Technologies and Systems (IKTS), the Fraunhofer Institute for Toxicology and Experimental Medicine (ITEM), the Fraunhofer Institute for Mechanics of Materials (IWM) and the Fraunhofer Institute for Digital Medicine (MEVIS). These institutions turned to AI and 3D printing to create customized finger implants. And though this project is just in the beginning, it shows the immense possibilities that open up when 3D printing is combined with software, AI and of course automation.

The Rise of Binder Jetting

And last, but certainly not least, we would be remiss if we did not mention one particular 3D printing technology that came up time and again in 2022: binder jetting. Though not always the most discussed out of the 3D printing technologies, binder jetting seemed to start to find its footing this year. Through new compatible materials and new actors on the field, it has earned its spot in our 3D printing trends for 2022.

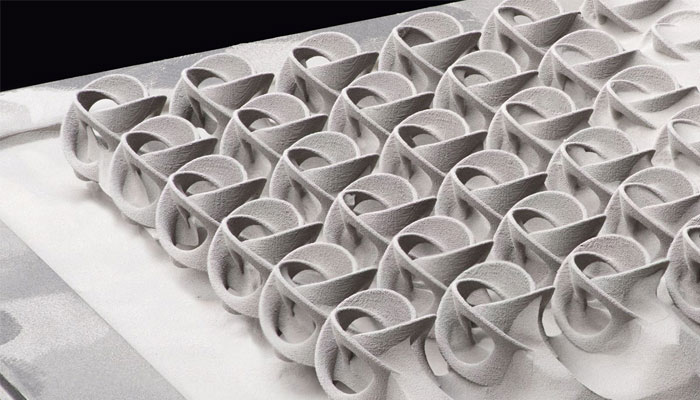

Photo credits: Digital Metal

First, material development was important for binder jetting in 2022. We can point to Desktop Metal in particular for its increasingly wide range of available materials. Though of course the company continued to invest heavily in both metal and sand, two of the most common binder jetting materials, with the launch of ExOne’s S-Max Flex Sand 3D printer especially, it also branched out. The company has invested in less conventional materials including wood binder jetting, rubber and even foam. This has allowed it to branch into even more industries and applications, firmly cementing the role of binder jetting for end-use parts as well as cores and molds.

Next, the binder jetting market was the one that seemed to change the most this year. After the acquisition of ExOne by Desktop Metal last year, the binder jetting market shrunk considerably as two of the biggest competitors joined together. However, as we mentioned earlier, now there are new players. One is of course Markforged.

The American manufacturer’s acquisition of Digital Metal has placed it firmly in the metal binder jetting market as well as positioned it as a direct competitor to DM in a number of fields. However that is not all! This year also marks the official launch of HP’s long-awaited metal 3D printing solution. Though HP uses its Multi Jet Fusion (MJF) process for its polymer solutions, its new metal 3D printer has turned to metal binder jetting. The Metal Jet S100 machine was first unveiled at IMTS 2022 this year and further showcased at Formnext.

The decision of both HP and Markforged to delve into metal binder jetting seems centered on the act that through the technology it is possible to achieve mass production of end-use metal parts. Ramon Pastor, global head and general manager of 3D Metals, HP Inc explained it thusly: “Since announcing the breakthrough Metal Jet technology in 2018, we have been working to develop the industry’s most advanced commercial solution for 3D metals mass production. 3D printed metal parts are a key driving force behind digital transformation and the new Metal Jet S100 Solution provides a world class metals offering for our customers, from the first designs right through to production, but more importantly helps them to realize the unlimited potential for digital manufacturing.”

And there you have it. Though of course we have seen continued examples of ongoing trends within the additive manufacturing sector, this year we had a few notable new ones. Between increasing consolidation, disruption in the sector, automation’s increasing role and of course the advancements in binder jetting, 2022 was certainly not a dull one. And we cannot wait to see what else awaits us in the 3D printing world in 2023.

What do you think of the 3D printing trends we identified for 2022? Can you think of any others? What do you think we can expect for additive manufacturing in 2023? Let us know in a comment below or on our Linkedin, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: 3Dnatives