What Types of 3D Printing Dyeing Solutions Are There?

Beyond its purely aesthetic function, color plays an important role in areas such as consumer goods, interior design, and even medicine. A colored 3D component can be produced in various ways: either directly with a multicolor 3D printer, through hand painting, or using devices specifically designed for coloring prints. Depending on the final application of the part, there are different options that allow for optimal color application. Although these devices are primarily intended for parts produced using the powder method, certain devices can also color components made with other processes, such as resin. Below, we have compiled a list of coloring systems currently available on the market. All of the listed devices provide a professional color finish suitable for industrial environments, take a look!

3DWAVE from Teknox

3D Wave is an all-in-one solution for coloring 3D-printed parts. The system was specifically designed for post-processing additively manufactured components, ensuring outstanding results with high precision even on complex surfaces. This is made possible by the Rotowave system. 3D Wave is automated and performs all necessary steps without unnecessary manual intervention. Pre-rinsing, coloring, rinsing, and drying all run automatically, simplifying operation. A complete cycle takes less than 60 minutes, highlighting the system’s efficiency. Users can also customize their programs according to their specific needs.

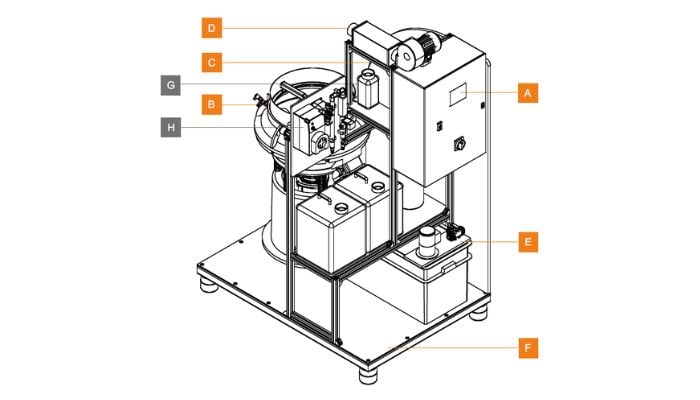

HAM-PD400 from HPRT

According to the manufacturer, the HAM-PD400 is an intelligent coloring system that serves as a complete solution for all your needs in liquid-dip coloring of nylon. With dimensions of 2000×1210×2000 mm and an innovative coloring technology, the HAM-PD400 stands out with a wide range of Pantone color options and an even, true-to-tone color application. This device provides an all-in-one operating system that handles everything from coloring and color changes to cleaning. Its intelligent color detection allows you to specify custom colors and materials, which can be applied seamlessly thanks to the HAM-PD400’s high precision. The processing time for a single piece ranges from 10 to 20 minutes. If you need a comprehensive coloring system for nylon, the HAM-PD400 is the perfect choice!

(Credit: HPRT)

eCOLOR

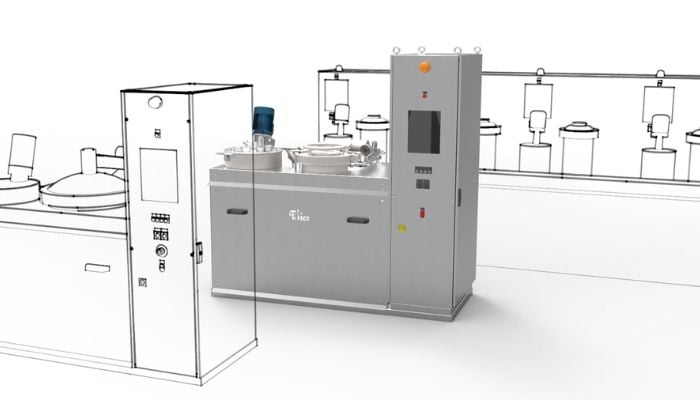

The eCOLOR series is the result of a collaboration between CIPRES and the traditional German manufacturer Thies GmbH & Co. KG, bringing decades of experience in textile dyeing to the world of additive manufacturing. Designed for large-scale in-house production, the product line includes three models: the eCOLOR Type 1/350/1 with a 350 mm dye bath, the Type 1/550/1 with a 550 mm dye bath, and the eCOLOR Quattro, which can perform up to four dyeing processes simultaneously. Each system operates fully automatically, combining efficiency with sustainability, making it well-suited for continuous industrial use. It can handle a wide variety of materials, from nylon, TPU, and ABS to polypropylene and reinforced polymers—regardless of whether the parts were produced using SLS, MJF, FDM, or SLA processes. The machines ensure consistently high color quality without oversaturation or bleeding, and users can store up to 999 dyeing recipes for repeatable results. With a starter set of five recipes and the option to customize additional ones, the eCOLOR series offers manufacturers a flexible, future-proof solution for reliable large-scale dyeing.

(Credit: CIPRES)

3DC Dyeformer

The Dyeformer from 3DChimera (3DC) was developed for coloring both powder-based (SLS, MJF, SAF) and resin-based (SLA, DLP, CLIP) parts. The device simplifies the process of dyeing 3D prints, eliminating the guesswork around the perfect temperature, time, and dye composition. 3DC offers eight different dyes that are compatible with the Dyeformer. All dyes are non-toxic and reusable for up to 24 hours. The Dyeformer can color both large and small parts and features an internal container measuring 1.5 × 19.5 × 6 inches, which can also be equipped with a smaller 16 × 8 × 4-inch stainless steel basket. To use the machine, simply mix the proprietary dye with water, and the machine heats it to a precise temperature, relaxing the polymer strands to permanently absorb the color.

(Credit: 3DChimera)

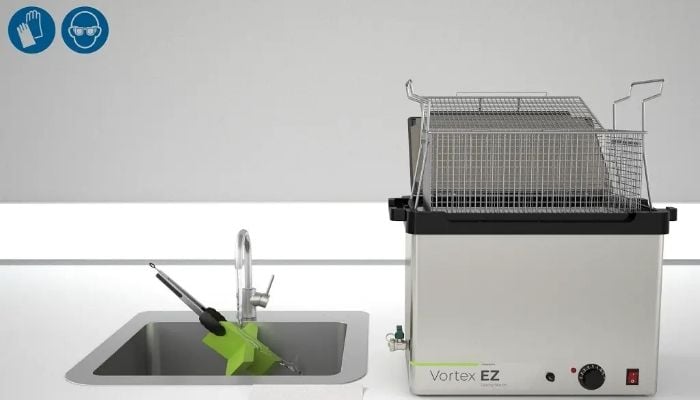

Xioneer Vortex EZ

The German company Xioneer specializes in 3D printing products such as washing stations, filament containers, materials, and, of course, the product we want to introduce today: the Vortex EZ dyeing station. Unlike the other solutions on this list, this is a dye tank that, due to its dimensions of 640 × 450 × 370 mm, its 38 L capacity, and its quiet motor, is considered a desktop device. The tank is made of double-walled, heat-insulated stainless steel, which increases efficiency and durability. It is suitable for parts produced using SLS, SLA, FDM, MJF, or SAF processes. The temperature can be set via a dial between 30 and 85 °C, and the liquid in the tank reaches its maximum temperature in about one hour.

(Credit: Xioneer)

DM60 from Dye Mansion

DyeMansion is a German manufacturer of post-processing machines for additive manufacturing. Its product lineup includes the DM60, which allows you to add color to your 3D-printed parts. The system is intuitive, easy to install, and fast. Simply scan the cartridge of your choice, insert it into the machine, place your cleaned parts in the container, and close everything. After 150 minutes, you can remove the basket, and your parts are ready to use! In terms of technical specifications, the device measures 950 × 600 × 945 mm, can heat up to 115 °C, and is compatible with SLS, SAF, MJF, and HSS 3D printing technologies. For anyone looking to color their parts black, a DM60 Black version is also available.

Dye tank from Ultrasonic Power

The Dye Tank solution, developed by Ultrasonic Power Corporation, was designed for the efficient coloring of 3D-printed parts in industrial environments. With a capacity of over 145 L and a heating power of 2000 W, it allows for rapid and even heating of the dye. Its internal dimensions of 81 × 46 × 41 cm provide ample space for parts of varying sizes, while the construction from double-welded 316L stainless steel ensures durability and resilience even under extreme conditions. The system features programmable digital controls for time and temperature, as well as a removable lid that reduces evaporation. The company also offers options such as the sparger-weir system, motorized lift, or an additional rinse tank, allowing the process to be customized and optimizing quality, efficiency, and repeatability.

(Credit: Ultrasonic Power)

SurfPro Steam Dyeing

The SurfPro from the French-Italian group IntegrAM is an automatic, steam-based dyeing system for SLS and MJF prints. It is a relatively new solution, designed for mass coloring of parts with a reduced environmental impact. According to the manufacturer, the SurfPro uses 1/10 of the water and 1/20 of the dye compared to conventional systems. What makes this machine special is its high-temperature steam system, which sprays the dye evenly onto objects with excellent penetration. This dyeing system is available in three different versions with volumes of 60 L and 120 L. Currently, only the Extra-Black color is available, which is highly sought after in the industry, but according to the manufacturer, many more colors will soon be available and can be swapped in just a few minutes.

(Credit: IntegraAM Group)

Which dyeing systems appeal to you the most? Let us know in a comment below or on our LinkedIn or Facebook pages! Plus, don’t forget to sign up for our free weekly Newsletter to get the latest 3D printing news straight to your inbox. You can also find all our videos on our YouTube channel.