What to Look For When Purchasing an Industrial 3D Printer?

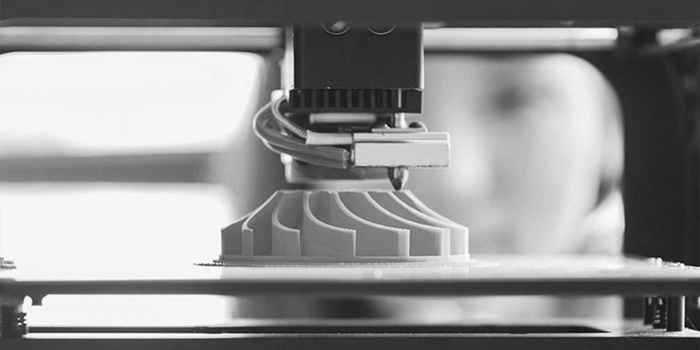

More and more companies are deciding to bet on additive manufacturing technologies, as it has been clear for some years now that it is the future of manufacturing. When we talk about 3D technologies, we are not only referring to prototypes, but also to high-quality end-use parts. With its adoption, it allows evolution in production and savings in costs and manufacturing times. Despite this, when choosing a machine, there are still doubts about parameters should be considered when getting an industrial 3D printer. Notably, users need to ask questions such as: What should be taken into account? Are the materials important? Today we will give an answer to some of these.

There are multiple 3D printing technologies currently available, so to narrow the scope, we will focus on fused material deposition technology. This technology has been mistakenly seen as linked to small machines for everyday use. However, thanks to the evolution of this technology and materials, we already think of it as an interesting technology for industry. But it is necessary to know how to differentiate between an industrial machine and a machine with a large printing volume.

What To Do Before Buying an Industrial 3D Printer?

Before making the decision to purchase an industrial 3D printer, it is important to create a list of what applications are being targeted for the machine and in which part of the production chain it makes the most sense to implement it. Once this is done, you can directly contact the manufacturer of the brand you are interested in. The important thing to take into account is to know the materials with which the machine should be working, if it is able to create quality end-use parts, and how big the printing volume is. Once we are clear about the quality/price relation of the machine, it is always possible to ask for a sample piece. This allows users to get a closer look at the printing quality of the machine.

Important Parameters To Consider

Although each company must take into account different characteristics to achieve the necessary performance, there are certain parameters that are important to take into consideration before choosing one brand or another. Some of the most important ones are the following:

- Print speed: This feature is directly linked to the performance a printer will have. Faster print speeds ensure lower printing costs.

- 3D printing with high-performance materials: High-performance materials are adopted mainly for their resistance to temperatures and stability. Therefore, a machine can be considered for industrial production if it allows the use of some materials such as PEEK, ULTEM, or composite materials that have carbon or glass fiber reinforcement. To prove that a machine can work with these materials, it must have a heated chamber that can exceed 170ºC.

One of the important considerations is compatibility with high-performance materials (photo credits: 3DGence).

- Dual extrusion systems: The possibility of using different extruders when working with an industrial 3D printer will allow duplicating production, but also using different materials in a part. Among the materials that we could highlight are the soluble materials, since they allow to increase the complexity in the design of the parts.

- Time-saving systems: a 3D printer should save us manufacturing time. It is important to think of machines with automatic calibration to shorten times. Worth mentioning is the possibility of working with software in the cloud, which will save us time when sending a file for printing.

- The total cost of an industrial 3D printer: When acquiring a 3D printer with these characteristics we seek to reduce costs, not generate them. Therefore it is important to take into account the materials with which we will be able to work. If it is a machine that allows third-party materials, or if it offers materials of your brand at reasonable prices.

In addition to these parameters, there are details that increase the efficiency of a machine. This includes the integration of a camera, cleaning systems, and automatic roll change, among many others. We know that finding an industrial 3D printer is not an easy task, but if you do it hand in hand with experts in the industry, you will find a machine that allows the increase in production you are looking for.

When adopting industrial 3D printing, we recommend consulting an expert in the field

What do you think of our recommendations for acquiring an industrial 3D printer? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: 3D Systems