What Polymer Materials Can Be Used to 3D Print Medical Devices?

3D printing is revolutionizing the medical industry, powering a broad range of applications from implants and surgical guides to patient-specific devices. Physicians and medical students alike are leveraging this technology to provide more targeted, individualized care. Key additive manufacturing methods—FDM, SLA, PolyJet, SLS, MJF, and LPBF for metal—offer distinct advantages based on the application and material. Selecting the right technology and biocompatible, certified materials is critical for optimal results. As new materials are constantly developed, the field continues to grow.

To dive deeper, we consulted Dinsmore, an ADDMAN Group company and leader in medical 3D printing. They shared insights on key polymer materials and applications shaping the healthcare sector.

Medical Device printed with MPU 100 (photo credits: Carbon 3D)

Medical Devices and 3D Printing: A Growing Market

Market research by The Insight Partners projects the medical 3D printing market will reach $10.65 billion by 2031, with a 17.5% annual growth rate. This rapid expansion is fueled by the technology’s core benefit: customization. Through imaging techniques like CT scans, MRIs, and 3D patient scans, highly personalized digital models can be created to match a patient’s anatomy precisely. Additive manufacturing also supports faster production cycles and a broad selection of materials, making it a versatile option for healthcare.

This approach allows for quick, accurate production of custom implants, detailed surgical guides for preoperative practice, and a range of medical devices—from prototypes to final products. Each process and material offers unique characteristics, suited for different applications and patient needs. Here’s a closer look at the polymer materials specifically formulated for medical devices and their compatible technologies.

Biocompatible Polymer Materials for Wearable Medical Devices

A primary application of 3D printing in healthcare is the creation of customized prostheses and implants. For these devices, biocompatibility is crucial since they make direct contact with the body. Different technologies can be used, with HP’s Multi Jet Fusion (MJF) being particularly popular due to its ability to produce small-scale parts with excellent surface finish, reduced print times and cost efficiency. MJF also provides sustainable options for recycling unused material.

White Nylon 12 PA, frequently used with MJF, is a favored biocompatible material for orthopedic prosthetics and implants. Certified for safe medical use and suitable for body contact, this material is also easily sterilized and customizable, with its white shade offering flexibility in coloring to meet specific needs.

Child medical helmet (cranial orthosis) used in helmet molding therapy to gently correct a baby’s skull shape. (photo credits: Carbon 3D)

In wearable medical devices, MPU 100 stands out as a key material, especially when used by Dinsmore with Carbon’s Digital Light Synthesis (DLS) technology. This resin-based method produces 3D-printed parts with qualities comparable to injection molding, delivering excellent mechanical strength, resolution and surface finish. MPU 100 is a rigid plastic known for its biocompatibility, durability and resistance to abrasion and chemicals, along with easy sterilization. These qualities make it ideal for customized medical devices and wearable prosthetics that demand patient-specific customization and long-term use.

Anatomical Models and Other 3D Printed Surgical Devices

Anatomical models, surgical guides and other medical instruments are popular examples of non-implantable devices created through 3D printing. When direct patient contact isn’t required, non-biocompatible materials can be used, particularly for device prototypes or developmental stages. Digital Anatomy Printing (DAP) brings these models to life with remarkable realism, a specialty perfected by Dinsmore. This technology accurately replicates the look and feel of human tissue, providing healthcare professionals and medical device companies with clinically versatile, repeatable, and precise anatomical models.

3D printing is widely used for producing both functional prototypes and end-use medical devices, often relying on ABS—a strong, durable polymer used in fused deposition modeling (FDM). ABS is especially suited for anatomical models requiring repeated handling.

For medical applications, Stratasys developed ABS-M30i, a biocompatible, medical-grade variant designed to meet healthcare standards. Known for its dimensional stability and heat resistance, ABS-M30i produces precise, durable parts that maintain their integrity under stress. According to Dinsmore, FDM 3D printing with ABS-M30i is ideal for robust, reliable medical components.

Medical device printed with ABS-M30i (photo credits: Dinsmore)

Dinsmore utilizes BioClear resin with Stereolithography (SLA) technology to produce robust, shatter-resistant medical parts. BioClear’s durability makes it ideal for creating non-implantable medical devices, especially in prototyping and development stages, where parts endure frequent handling and must remain intact through rigorous use. This resin’s strength minimizes the risk of breakage during shipping and medical procedures, while its ability to capture intricate details allows for the production of high-precision prototypes and components essential in medical applications.

Medical prototype printed in BioClear (photo credits: Dinsmore)

Another advanced technology used by Dinsmore for medical devices is Axtra3D’s Hybrid PhotoSynthesis (HPS). This method merges the strengths of SLA and DLP, offering high accuracy and speed. One standout material used with HPS is Evonik 6100, a high-performance resin known for its impressive tensile strength and heat resistance.

Evonik 6100, combined with HPS, enables the production of complex medical components that demand extreme precision and durability. Its chemical and thermal resistance allows these devices to withstand challenging environments, repeated sterilization and high-temperature medical applications, making it ideal for critical healthcare use.

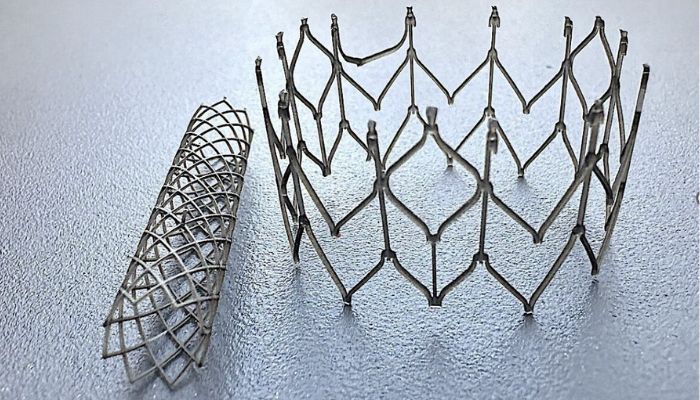

First trial Mirco-Stent printed by Dinsmore with Lumia.X1 resulting in 300 µm (photo credits: Dinsmore)

These examples showcase just a fraction of the polymers available for 3D-printed medical devices. As the market evolves, new solutions, technologies and materials are continuously emerging. Additive manufacturing (AM) has proven to be both faster and more precise than traditional methods, enabling fully customized devices in both form and material.

With ongoing research and development, these polymers promise even more transformative applications, advancing personalized healthcare to be more accessible and effective. Dinsmore’s expertise highlights the potential for delivering safe, durable and tailored solutions through 3D printing in the medical field. Learn more HERE.

What do you think of the different polymer materials available for 3D-printed medical devices? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

Cover picture: Anatomical Model of patient spine (photo credits: Dinsmore).