What is Autodesk Inventor and How Does it Work?

In any printing process, the first step is the digital design of the model to be manufactured. For this, there is a wide variety of design tools available on the market. From basic solutions for beginners to advanced software for professionals, the options are numerous. Among these programs is Autodesk Inventor. Developed by Autodesk, this is computer-aided design (CAD) software for modeling, simulation, visualization and documentation. Inventor facilitates the integration of 2D and 3D data in a single place, creating a virtual representation of the final product that enables users to validate form, fit and function before manufacturing. Autodesk Inventor also includes parametric modeling, direct editing and free-form tools, as well as multi-CAD translation capabilities in its standard DWG computer drawings (DraWinG). To find out more about this software, read on in this comprehensive guide.

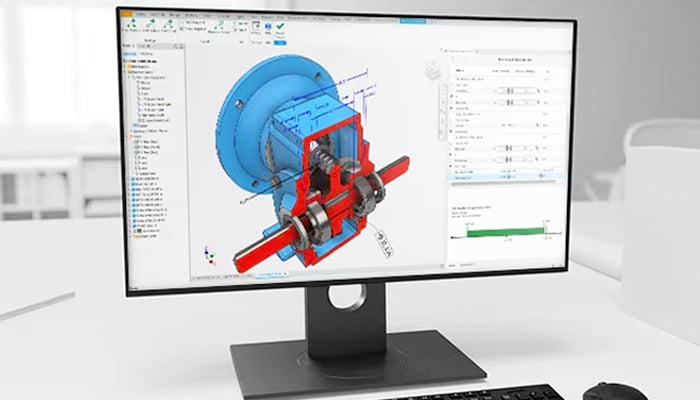

Inventor uses ShapeManager, Autodesk’s proprietary geometric modeling kernel. The CAD software therefore combines parametric design capabilities: direct, free-form and rule-based. With this professional solution, you have integrated tools for sheet metal, frame, tube, cable and harness design, layout, rendering, simulation, machine design and much more. What’s more, it supports TrustedDWG® files and offers powerful model-based definition features for integrating manufacturing information directly into the 3D model. It is widely used by mechanical engineers who need specialized, automated tools to design and prepare for manufacturing.

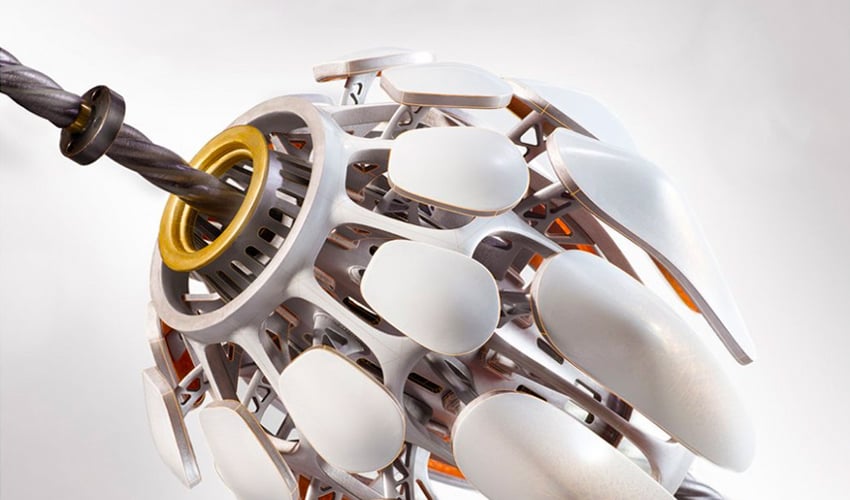

Inventor provides the tools needed to control and manage the data generated by complex assembly designs (Photo credits: Autodesk Inventor)

The Features of Autodesk Inventor

Parts are Inventor’s main building blocks. They are created by defining features, which in turn are based on sketches (2D drawings). Working drawings can also be used to produce sketches at different points in the workspace. The advantage of this design method is that all sketches and features can be corrected at a later date, without having to redo the entire partitioning. This modeling system is more intuitive than previous, older tools, where modifying basic dimensions is required starting from scratch. To continue the process, parts are linked together to form assemblies. In this way, by modifying the parts and assemblies, different variants of the product can be obtained. Parts are assembled by adding constraints between surfaces, edges, planes, points, and axes. This modeling method can be used to create large, complex assemblies.

Example of a model in Autodesk Inventor (Photo credits: Autodesk Inventor)

Using Autodesk Inventor for 3D Printing

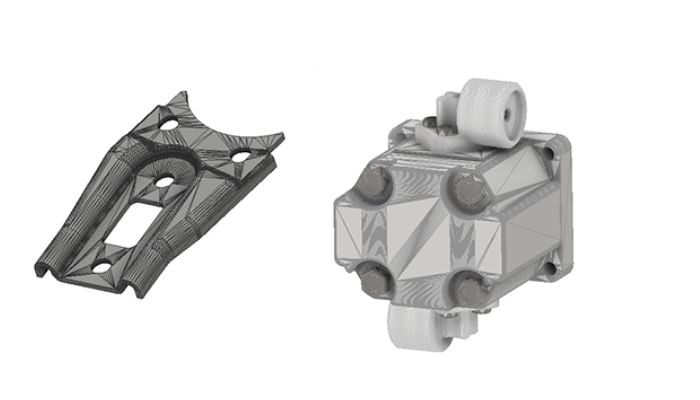

Autodesk Inventor is one of the world’s most widely used 3D mechanical CAD design programs for creating 3D digital prototypes used in product design, visualization and simulation for mechanical design. It uses parametric solid modeling techniques to rapidly modify and adapt the geometric characteristics of the product design, thanks to a highly intuitive workflow. In 3D printing, the aim is to produce correctly meshed models, to be exported as STL files. A 3D model created with Autodesk Inventor software will result in a closed design and perfect meshing.

Within this software is a specialized 3D printing tool. To find it, navigate to the top bar and go to the panel called “Environment”. Clicking on this tool brings up a representation of a printing plate. This tool is designed to work with an Autodesk Ember printer or other 3D printers. From this environment, we can now define the orientation of our part, do direct modeling if we need a slightly larger part, and so on. What’s more, users have the option of sending the part to Autodesk Print Studio, Meshmixer or directly to the desired printer. With the Print Options tool, you can fine-tune mesh structure, units and even the color.

Example mesh created with the software (photo credits: Autodesk Inventor)

The Latest Version, Inventor 2024

The latest version of Inventor® 3D CAD software is packed with updates and enhancements of interest to a wide range of industries. All these changes, inspired by user feedback and requests, facilitate design management, reduce repetitive tasks and speed up engineering workflows. Among the many new features in this new version is the ability to create a design inspection plan by sending models directly to Fusion 360.

A new feature enables iLogic code to be applied directly with Vault to perform operations such as copying files, defining numbering schemes, and extracting documents. In addition, they have optimized model-based definition for documentation workflows in the 3D environment. This release also features performance and productivity enhancements, notably for graphics and large assembly management.

Autodesk Inventor is available as a free 30-day trial, after which payment is by subscription. To start using Autodesk Inventor, you can take out a subscription for $305 per month. On the other hand, an annual subscription costs $2,440, or you can opt to pay $7,320 for a three-year subscription. If you’re thinking of buying this software solution, you’ll find more information on Autodesk’s official website, HERE.

What do you think of Autodesk Inventor? Do you use it as your go-to CAD software? Let us know in a comment below or on our Linkedin, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.