What Are the Advantages of Using Grasshopper for 3D Printing?

Created in 2007, Grasshopper is an algorithmic modeling tool that runs inside Rhinoceros CAD software. Previously an installable plug-in, the tool has been fully integrated into Rhino 6 and all subsequent versions. An easy-to-learn CAD program, Grasshopper is based on mathematical representations that can be used to model any 3D shape. In fact, each component is represented in the form of a box: the user can connect the various boxes together, thus obtaining a node diagram that describes the relationship between each block. So there’s no limit to the complexity, degree or size of your models. But what are the advantages of Grasshopper? And why is it worth using for 3D printing?

Unlike other programming languages, such as RhinoScript or rhino.Python, Grasshopper does not require any prior knowledge in programming or coding. On the contrary, the plug-in allows developers and designers to create generative algorithms without having to write codes. This is because changes are visualized through a node diagram that describes each of the mathematical and geometric relationships of a three-dimensional model. Since shapes can be created from data, one of the main advantages of Grasshopper is the ability to change geometry almost infinitely by simply changing parameter values. Moreover, changes can be made without having to cancel or restart the design. But what happens when this program is combined with additive manufacturing technology?

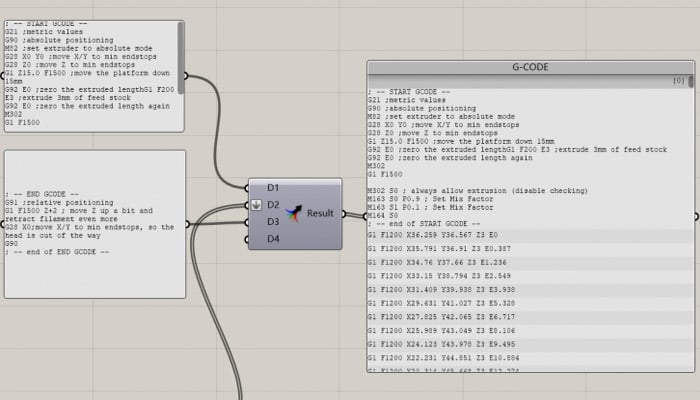

G-code generation via Grasshopper (Photo credits: Eazao)

3D Printing and Grasshopper

As you can imagine, if you can modify the geometry almost ad infinitum, it’s a windfall for additive manufacturing. What’s more, the idea of using a kind of flowchart capable of understanding the relationships between different boxes means that not only can a 3D design be created, but also a G-code that can be run on a 3D printer. This means that the user doesn’t have to go through the slicing stage. To obtain the G-code, the model needs to be deconstructed into polylines and points with X-Y-Z coordinates need to be created for the printer. With this system, it is possible to adjust the print and create, for example, non-flat slices with layers of different heights. Unlike traditional slicers, which cut the STL model into equal horizontal layers, this plug-in offers more advanced control over extruder movements.

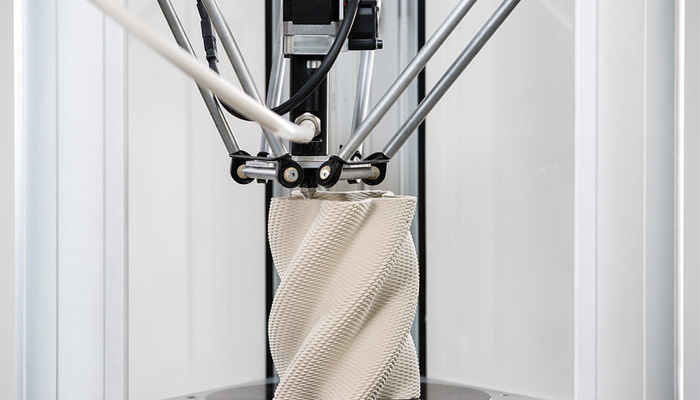

Grasshopper is particularly interesting for the production of ceramic parts, or those using materials with a higher density than thermoplastics. Liquid Deposition Modeling (LDM) technology, for example, is used by Italian company WASP to extrude materials such as ceramics, porcelain, clay, alumina, zirconia and other high-performance ceramics to promote digital craftsmanship and in-house production. With manufacturing methods like these, there’s no slicer software to prepare a file for subsequent 3D printing. That’s where Grasshopper comes in.

Grasshopper is particularly interesting for ceramic 3D printing (photo credits: WASP)

Among other things, the program allows you to customize fills, use open-source objects, work with intersections, create patterns and choose the path the extruder will follow. It facilitates the creation of lattice structures, optimizing the quantity of material to be printed and the weight of the final part. Finally, Grasshopper simplifies the creation of iterations: by adjusting the parameters of our diagram, we can imagine multiple designs very quickly and with fewer errors. For more information on Grasshopper, click HERE.

Do you use Grasshopper for your 3D printing projects? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: Steampunk Pavilion © Tõnu Tunnel