New 3D printer from WASP prints medical-grade PEEK from pellets

During Formnext 2019, the 3D printer manufacturer WASP launched a new solution that prints medical-grade PEEK from pellets. WASP has gained recognition in the industry for its 3D printers dedicated to the construction sector – today it is bringing its expertise in 3D printing technologies to the healthcare sector. The manufacturer identified the benefits additive manufacturing can bring to the medical sector, particularly in terms of offering personalised products to patients. In this context, the company is bringing a new line of 3D printers to the market, the Delta WASP Tech Line.

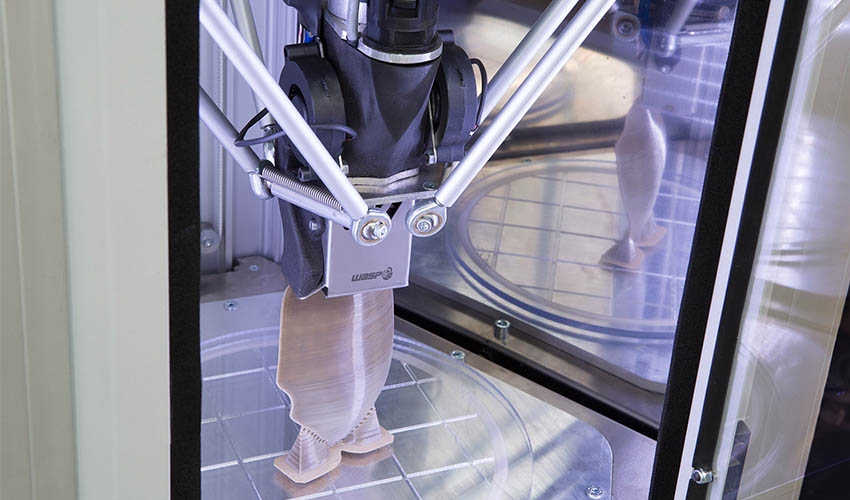

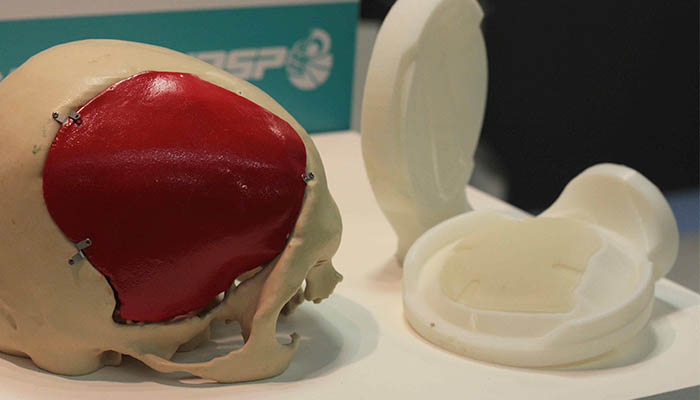

Printing medical-grade PEEK makes it possible to produce implants from digital designs with a material that has uncomparable performances at a relatively low-cost – something that can revolutionize the field of implants. High-performance thermoplastics such as PEEK have the advantage of being biocompatible, resistant, lightweight and relatively affordable. For the company, the idea of printing the PEEK implants from pellets came from the long research carried on with Dr. Villiam Dallolio on the creation of cranial prosthesis with 3D printers.

PEEK implants from pellets came from the long research carried on with Dr. Villiam Dallolio on the creation of cranial prosthesis with 3D printers | Credits: WASP

Tests on this research show how the resistance of the prosthesis is outstanding, yet very light. Dr. Villiam Dallolio explains that the prosthesis after the print can be also processed with annealing at 200°C in the oven to improve the mechanical performance even more. In the near future, the company has stated it will be working on a complete system, including software, 3D printer and materials to produce the prosthesis from the CT of any patient. “PEEK pellet printing is undoubtedly a revolutionary application and the impact of this innovation on the entire WASP-printers-line is extraordinary,” the company stated in a press release.

In general, the company is better known for offering additive manufacturing solutions for the construction sector. In fact, WASP has been working on the principles of circular economy since 2012 in order to build 3D printed houses in the shortest period of time and in the most sustainable way possible. In October, the company unveiled its TECLA prototype, a new circular housing model, created using entirely reusable, recyclable materials taken from the local terrain.

The Delta WASP 3MT CONCRETE 3D printer | Credits: WASP

Finally, this new launch doesn’t come alone. The company also showcased its Delta WASP 3MT CONCRETE 3D printer at the fair for additive manufacturing in Frankfurt. This novelty enables to print large, fluid and dense materials, allowing materials like concrete to be 3D printed through a continuous feeding method. Last but not least, the company also presented its new Delta WASP 3MT INDUSTRIAL 4.0 3D printer. The special feature on this system is that it boasts a continuous feeding system and optimized extruder so that it can print 100% recycled pellet polymers.

You can find more information on WASP’s website HERE.

What do you think of the Delta WASP Tech Line? Let us know in a comment in the section below or on our Facebook and Twitter pages! Sign up for our free weekly Newsletter, all the latest news in 3D printing straight to your inbox!