Volvo Embraces 3D Printing With Titomic’s Cold Spray Technology

Repeatedly, we’re exposed to the groundbreaking applications of 3D printing within the automotive and transportation industries, showcasing the immense potential of this technology. Numerous car manufacturers have embraced additive manufacturing in their production processes. Take, for instance, the Swedish Volvo Group, headquartered in Gothenburg, which has recently opted to integrate 3D printing technology from Australian industrial machinery manufacturer Titomic. Titomic specializes in the fabrication, coating, and repair of metal components, catering to sectors like aerospace and automotive.

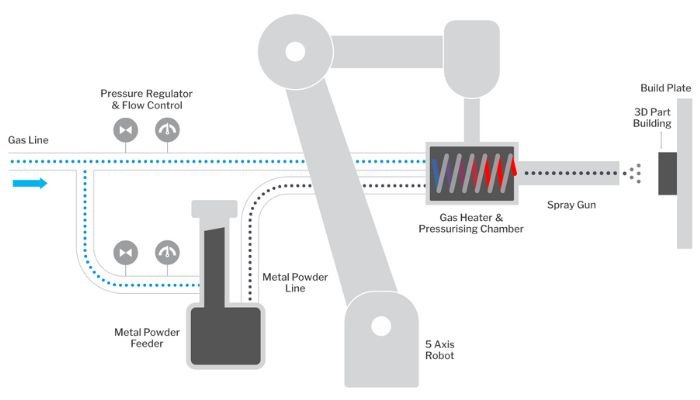

Volvo has six plants worldwide and is a major player in the automotive, heavy machinery, and MRO sectors. The company is also one of the largest truck manufacturers in the world. Recently, Volvo has implemented Titomic’s cold spray technology, an advanced additive manufacturing method that coats surfaces with thick layers of specialty metals without melting them. More specifically, it involves the D523 low-pressure cold spray system, which Volvo purchased for a price of €55,000. Currently, the company plans to integrate the technology into its repair and overhaul operations, so the sale is also an indication of the increasing relevance of Titomic’s technology in the maintenance, repair, and overhaul (MRO) sector, representing a step forward for the company in this area.

Titomic’s cold spray technology (Photo Credits: Titomic)

However, the integration of this system is far from being Titomic’s first venture into the operations of prominent market players. Previously, Titomic has supplied companies such as MTU Power and Rolls Royce with its technology. The adoption of additive manufacturing technology by major, renowned companies underscores the vast potential and opportunities inherent in 3D printing. Volvo’s product range encompasses not only mining trucks but also marine engines, showcasing the versatility of this technology. Titomics D523 will be used for the maintenance, repair and overhaul of Volvo’s heavy machinery engines. The technology will be used in particular in Volvo Trucks and potentially in Volvo Construction Equipment. Titomic’s CEO, Herbert Koeck, had the following to say about the sale of the 3D printing machine to Volvo:

The integration of Titomic’s D523 into Volvo Group’s repair operations is a key win. Volvo’s adoption of this technology demonstrates the strong performance of Titomic’s products and growing interest in them across Europe and the worldwide remanufacturing and maintenance sector. This sale opens avenues for additional sales within Volvo and strengthens the evidence of Titomic’s technology’s impact in the remanufacturing and maintenance sectors, enhancing Titomic’s ability to pursue sales effectively within remanufacturing and across various industries.”

What do you think of Volvo’s adoption of Titomic technology? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.