ViscoTec Makes Liquids and Pastes Compatible With 3D Printing Thanks to Innovative Printheads

ViscoTec offers high-precision dosing pumps and systems that are used all over the world. Customer satisfaction is always at the forefront of the company’s activities, which is why it has enjoyed considerable success since its founding back in 1997. Starting in Bavaria, ViscoTec’s international expansion began in 2009 with the founding of ViscoTec America in Georgia, followed by the establishment of a branch in Singapore in 2011, China in 2013, India two years later and finally ViscoTec France in Mérignac in 2019. Locations in Hong Kong and Denmark followed in 2022 and 2023. The dosing systems and components are used around the globe to dose, fill or remove liquids and pastes. ViscoTec is also applying this principle to 3D printing, thereby opening up a new group of materials for additive manufacturing. The company’s printheads can bring liquids and pastes into three-dimensional form. This approach is particularly interesting for silicones, ceramic pastes and polyurethanes. We spoke to Johanna Bruckhuber to find out more.

3DN: Could you briefly introduce yourself and your role at ViscoTec?

Johanna Bruckhuber

My name is Johanna Bruckhuber and I have been a Business Development Manager at ViscoTec in the field of additive manufacturing for two years. Before that, I completed my master’s degree in medical technology at the OTH Amberg-Weiden. My tasks at ViscoTec include the sales and marketing of our 3D printing products. Our team consists of me and my colleague Mr. Kasböck, who has been responsible for the products and their technology in 3D printing for more than six years now.

3DN: What does ViscoTec do and what is its mission?

ViscoTec has been manufacturing dosing systems and components for an international customer base for 26 years. These are used for conveying, dosing, applying, filling and dispensing liquids and pastes.

This know-how, together with the core technology – the endless piston principle or progressive cavity technology – has since been used in numerous industries. To give some examples, you can find us in sectors like electronics manufacturing, hygienic applications and even commercial developments.

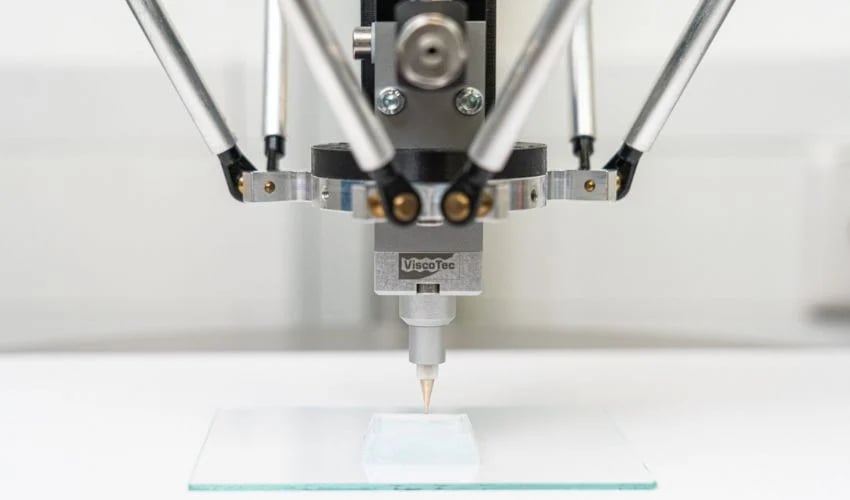

This also includes additive manufacturing. We have been developing print heads in-house since 2015 and they have since been successfully used in extrusion-based 3D printing with fluids and pastes.

ViscoTec’s 3D print heads are based on the endless piston principle (photo credits: ViscoTec Pumpen- und Dosiertechnik GmbH)

3DN: Could you tell us more about your 3D printing solutions?

With the vipro-HEADs, one- and two-component materials can be processed with a high degree of accuracy! Due to the design of the print heads with the aforementioned endless piston principle, pastes with a viscosity of up to 1,000,000 mPas can be printed.

Thanks to the endless piston principle, the material is dispensed volumetrically in a way that is gentle on the product. In addition, the so-called “retract”, which is well known in 3D printing, can also be used in liquid 3D printing, allowing precise start and end points to be realized without dripping. The materials are processed with a dispensing accuracy of up to 99%, regardless of viscosity.

If the configuration of the print heads is adapted accordingly, it is also possible to process filled substances. These can contain abrasive fillers, for example. Colors or additives can also be added. Better process stability can also be achieved with an optional heating function.

3DN: Which technologies, materials and printers are compatible?

Basically, our process is similar to fused filament fabrication (FFF). The print head conveys the medium volumetrically from the dispensing needle. It applies line by line, creating a three-dimensional structure.

The vipro-HEADs are compatible with commercially available printers and slicer programs. This means that the vipro-HEADs can be easily connected to almost any existing 3D printer. The control is “plug and play” via the signals of the 3D printer. Our dosing heads thus expand the range of applications of 3D printers with minimal effort in the field of fluid printing. They can be used to print silicones, UV adhesives, ceramic pastes, polyurethanes, epoxy resins and metal pastes, for example.

3DN: Which applications benefit most from your solution and who are your customers?

In principle, printheads are always of interest wherever 3D printing is concerned: e.g. when it comes to the rapid development of new products without costly injection molding tools, the production of small series on site or the personalization of an end product.

In addition, purely volumetric conveying allows the material properties of standard materials to be retained. A good example of this is silicone, which is popular in numerous applications due to its properties such as biocompatibility, durability, thermal stability and elasticity. With the vipro-HEADs, high or low viscosity silicones, RTV silicones or LSRs can be easily processed.

The 3D printing of real silicones is therefore a benefit for numerous industries, such as the healthcare sector. One example here would be the 3D printing of anatomical models made of silicone, e.g. the aorta from 3Deus Dynamics for surgery preparation or training for surgical procedures.

3D-printed aorta made from silicone (photo credits: 3Deus Dynamics)

Our products are aimed at anyone who wants to expand their range of processable materials to include liquid or paste-like substances. These include

- 3D printer manufacturers who want to give their customers the option of processing these media

- Material manufacturers who want to get involved with 3D printing their materials or adapt them to 3D printing

- Research institutes, which particularly appreciate the wide range of materials that can be processed

3DN: Do you have any last words for our readers?

This year, we will be launching a new product on the market that will offer major benefits in the field of additive manufacturing in the medical technology sector in terms of compliance with guidelines and cleaning.

We will also be attending numerous trade fairs this year, the next ones being Silicone Expo in Amsterdam in March and Rapid + TCT in Detroit in April, where we are looking forward to innovations in the 3D printing market and new partnerships. You can find out more about ViscoTec on our website HERE.

Bild: ViscoTec Pumpen- und Dosiertechnik GmbH

What do you think of ViscoTec? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: ViscoTec Pumpen- und Dosiertechnik GmbH

I hate those pumps. We used them at a waste water plant. No way to trouble shoot them they either work, work like crap or don’t work. Then you have to replace everything and its a super PIA to do