The Vertigo MK1: The 3D Printer With an Innovative Auto-Ejection System

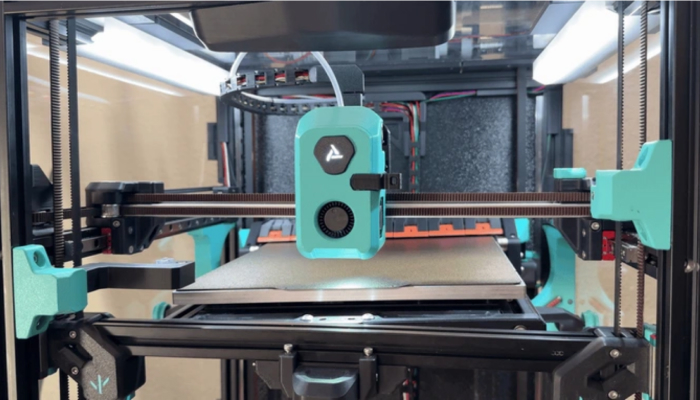

In recent years, there has been growing interest in 3D printing automation, particularly in print farms and professional environments looking to optimize their processes and reduce the need for intervention. The Vertigo MK1, currently campaigning on Kickstarter, promises to provide an innovative solution thanks to its unique auto-eject system.

Designed by Automated Layers, this printer aims to solve the limitations of traditional printers, while remaining accessible to professionals and enthusiasts alike. Find out how it works, its advantages and the markets it is targeting.

With a heated build plate capable of reaching 120°C and a print chamber up to 50°C, the Vertigo MK1 is compatible with a wide range of filaments.

A Printer Designed for Automation and Reliability

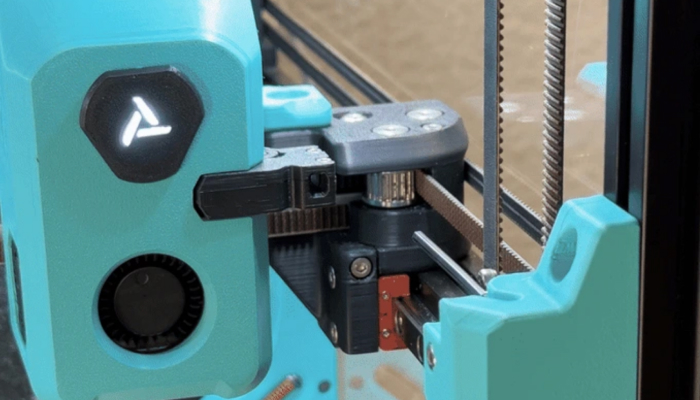

The main innovation of the Vertigo MK1 is its auto ejection system for printed parts. Unlike traditional approaches using the print head to push the parts, or systems requiring external modifications or costly accessories, the MK1 has integrated a native dedicated ejection solution.

After each print, the heated bed rotates vertically through 90°, is rapidly cooled by four fans located under the bed, and uses a bar equipped with a nylon scraper to remove the part without damaging the print surface or exerting forces on the movement system. This approach guarantees compatibility with a wide range of geometries and materials.

Technical highlights:

- Heated chamber: maintains an internal temperature of 50°C to facilitate the printing of technical materials such as ABS and ASA, reducing the risk of deformation.

- Heated print bed: Rises to 120°C in less than two minutes and cools three times as fast, according to Automated Layers, thanks to built-in fans.

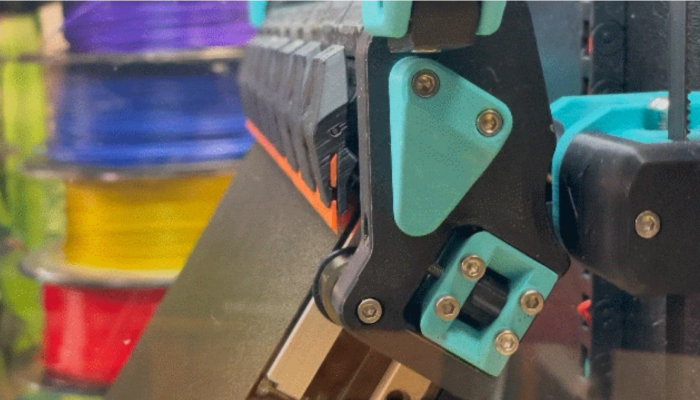

- CoreXY system: enables print speeds of 300 mm/s and accelerations of up to 30,000 mm/s² to be achieved, on paper at least.

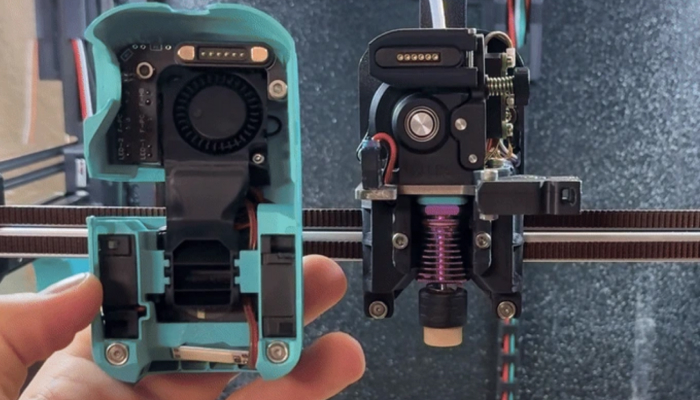

- Automatic leveling: Improves printer reliability by ensuring optimum first-layer printing thanks to an E3D Revo PZ probe integrated into the printhead.

- Open-source: Inspired by Voron printers, the MK1 is entirely open-source.

The Vertigo MK1 uses a tilting bed and scraper to eject 3D printed parts.

Why Automate 3D Printing?

According to Automated Layers, the creators of the Vertigo MK1, their project came about as a result of their own frustrations using their print farm. They were using traditional automated 3D printers to eject parts with the print head. Problems with this type of automation included reliability and limited compatibility with certain materials. With the MK1, they wanted to offer a more suitable solution that could automate continuous printing, thus reducing the manpower required and maximizing printer utilization.

In internal tests, the team claims to have achieved non-stop printing for 200 hours, consuming 5 kg of filament without the slightest human intervention. While these results are impressive for a prototype, it remains to be seen how this performance translates into various environments on production machines.

The Vertigo MK1 features an easily accessible print head, facilitating maintenance.

A Booming Market: What Are the Other Offerings Out There?

The Vertigo MK1 is not the only printer to offer automatic ejection in 3D printing. Several solutions exist, each with its own specific features and limitations:

- Robotic arms (e.g. Mira from Cosmyx)

The robotic arm integrated into Cosmyx’s Mira system is used to change the printer platen and eject the printed parts. Although this solution is best suited to industrial production, it represents a substantial investment for small structures or private individuals.

- Modular systems (e.g. Array from Mosaic Manufacturing)

The Array combines up to four printers in a single unit, with automated management of materials and print trays. Similar to the Mira, the Array uses a robotic arm to change the printer tray and store the tray with the 3D print on a shelf. Like the Mira, it’s an ideal solution for high-volume production, but represents a significant investment.

- Conveyor belt printers (e.g. Creality CR-30)

Creality’s CR-30 is equipped with a conveyor belt for printing mass-produced parts, which detach from the build plate when it reaches the end. Although this solution makes it easy to unhook prints, and is attractively priced, it poses other problems.

In fact, the print head is oriented at 45° to the build plate, which means that printing and slicing constraints should not be underestimated. What’s more, this type of printer is notoriously difficult to level, leading to premature unhooking of parts during 3D printing.

- Head ejection systems (e.g. Cartesian FDM printer with customized G-code)

It is possible to create a custom G-code script to eject parts with the post-printing print head. This procedure is relatively simple for basic parts, but can damage more fragile 3D prints, as well as the printer itself.

Unlike the above approaches, the MK1 offers a compact, all-in-one solution, designed from the outset to incorporate automatic ejection, without requiring external modifications or sacrificing print quality.

The Vertigo MK1 uses Klipper firmware and the Mainsail interface, and has a print volume of 220 by 220 by 250.

A Successful Kickstarter Campaign

Recently launched, the Kickstarter campaign for the Vertigo MK1 has already exceeded its initial target of $25,000 (almost doubling it at the time of writing), with 20 days of funding still open at the time of writing. Contributors can choose from different levels of participation:

- Vertigo MK1 – Hardware Kit (including the hardware but not the parts for assembly): $2,250

- Vertigo MK1 – Standard Kit (including all parts and ready to assemble): $2,625

- Vertigo MK1 – Assembled: $5,000

Despite all this excitement, it’s important to remember that crowdfunding campaigns carry risks, particularly when it comes to production and delivery. The team has announced a delivery date of May 2025, so we’ll have to keep an eye on the project’s progress until then. If you’d like to find out more about the project, you can visit its Kickstarter page HERE.

The Vertigo MK1 uses linear rails to guarantee precise movements.

What do you think of Automated Layers’ Vertigo MK1? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.