Velo3D on Creating Large, Mission Critical Parts With Metal Additive Manufacturing

Founded in the United States by Benny Buller, Velo3D is known for its metal additive manufacturing solutions especially in sectors like aerospace. Not only do its solutions essentially eliminate the need for Design for Additive Manufacturing (DfAM), allowing for less compromising in the creation of parts, but all their metal solutions are fully integrated, giving users freedom to print the parts they want. And in the past few years they have just continued to grow. We spoke to Dirk Rathsack, the managing director for sales at Velo3D, to learn more about its solutions, its current expansion into Europe and more.

3DN: Could you introduce yourself?

My name is Dirk Rathsack, I am the managing director for sales, I joined Velo in April this year and the connection I have in 3D printing is that my previous employer was Protolabs. It was a rapid manufacturing company and a couple of technologies, headquartered in Germany. I was introduced over the past six years to polymer and metal additive manufacturing in my job as a sales VP and I am now excited to be working with Velo3D and its innovative 3D printing solution as it expands into Europe.

My name is Dirk Rathsack, I am the managing director for sales, I joined Velo in April this year and the connection I have in 3D printing is that my previous employer was Protolabs. It was a rapid manufacturing company and a couple of technologies, headquartered in Germany. I was introduced over the past six years to polymer and metal additive manufacturing in my job as a sales VP and I am now excited to be working with Velo3D and its innovative 3D printing solution as it expands into Europe.

3DN: Could you tell us more about Velo3D?

Velo3D is a technology manufacturing company with fully integrated metal AM solutions for mission-critical parts. Our customers tend to have difficulties producing their parts with first generation 3D printing or with traditional methods, and we are seeking to overcome those design challenges. What we are doing is helping customers to print or manufacture their part without compromising on quality.

For us, mission-critical parts are those that are necessary to the function of what they are doing. A rocket engine would be a mission critical part, because if this does not function, then your mission is in jeopardy. And you need to make sure these kinds of parts are manufactured in a way to optimize the functionality of the part while reducing weight or increasing lifetime, or reducing costs if they are so critical. And that is where our solutions come in.

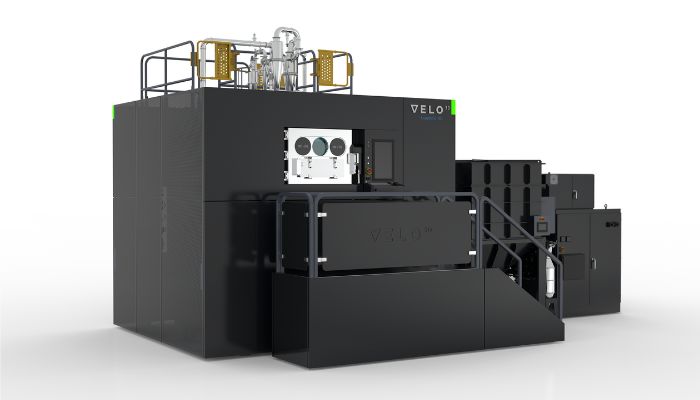

Velo3D is known for its Sapphire range of fully integrated metal additive manufacturing solutions (photo credits: Velo3D)

As such, we are looking for customers that are looking to produce end-use parts on our machines, our aim is to help customers adopt our technology and produce parts for their applications. We are not in the business of research and development or prototyping but our true value will come across most if a customer is looking to adopt AM technologies for their final parts.

3DN: Velo3D is especially known for laser powder bed fusion. How does the solution work? What are the benefits of using it?

We are what we call a fully integrated metal am solution and what we mean by that is that we are not only delivering or giving our customers the hardware, but also aspects like the print preparation with Flow™ Print Preparation Software which is a proprietary solution developed by Velo3D to allow users to go from the CAD file to preparation to optimization for printing. We use a large suite of predefined and revision-controlled parameter sets that prepare the file in a way to make sure it is consistent, high quality and repeatable on all our machines.

Of course, we also have the printers. We have a nice range of different sizes of printers going from the standard Sapphire®, with a small build plate, to the Sapphire XC. You can expand even up to a meter with the Sapphire XC 1MZ solution. All these use the same software so you can start on a Sapphire® and then you could easily transfer to the Sapphire XC and print there. Last but not least, the package and solution are completed with Assure™ Quality Control Software which uses data before and during the print process in order to give the customer the opportunity to have full visibility of and understand the quality of the 3D printed part at any part of the process. This as well helps to ensure that standards are met while printing your parts.

One of the reasons why we can help customers print parts that they struggle with is that we have the ability to print parts with a much lower angle and much flatter geometries on our system than any others. This means that our users have far less limits especially when it comes to design. Another factor, is what I mentioned, the data that we provide in order to validate the quality of each part and continuously improve our solutions.

Velo3D’s technologies can be used for parts in a variety of sectors including aerospace. In this image you can see a propellant tank from Launcher (photo credits: Launcher)

And in terms of large-scale 3D printing and its benefits? In traditional manufacturing, they produce a number of different parts all belonging to a single application and assemble it to find the final part. Well, if you have a big enough build chamber you can basically integrate all the different parts into one and just make one part. And the place where we see the most adoption is aerospace but also in sectors like oil & gas.

3DN: Velo3D has been expanding into Europe lately. Could you tell us more about your projects?

That’s why I’m here, to help Velo3D to really expand our footprint into Europe. It’s true that we have been mainly successful in developing in the US for our American customer base. And in the beginning of last year, the management team said we need to expand into Europe because there we see similar applications and industries where we have a strong footprint such as space, oil & gas, aerospace, etc. If you think about it, the second biggest airplane manufacturer is European. We see a lot of similarities in terms of target industries and markets to what we’ve been seeing in the United States. As such, it made a lot of sense to make that step.

Currently, we are focusing on four main markets in Europe: the UK, Germany, France and Italy. There we have established local teams who speak the local language to make sure that we provide the support customers are expecting and industry-wide we are targeting similar markets. We have some good footprints in space and aerospace, so it makes sense that we are talking to the main aviation companies across Europe. And especially with the current geopolitical challenges, there is a huge amount of pressure right now to innovate in the oil & gas industry. Our solutions can help increase productivity in the sector so that is also an area where we are developing even more. So that is what we are currently focusing on.

3DN: Formnext is coming up, will Velo3D be there? What can attendees expect?

Formnext is an important event for us as we will be able to meet the industry and the users who are interested in our technology. We will have an interesting selection of products to show. Additionally, we will showcase some of the new parts coming from the bigger machines. Attendees can expect demo parts, including those showing capabilities for large parts, with examples from all our solutions displayed.

An engineer with parts made of M300 Tool Steel, Velo3D’s latest qualified material (photo credits: Velo3D)

Apart from that, we will show some new materials in combination with the applications and large parts. We will have a copper alloy product at the booth as well as an M300 Tool Steel application. We are going to demonstrate why we started our journey in the Aerospace and Space industry. At the same time, we will show how we have expanded into industries like heavy industry, power generation, oil & gas, automotive, tooling, and more. All of which will of course be on display. We want to show that we are able to help anyone no matter their needs in metal additive manufacturing.

3DN: Any last words for our readers?

When I talk to people who do not fully know who we are, I try and summarize this in a sentence which goes like this: if you have a challenge manufacturing parts that are critical to you without compromising on design, quality or performance or if you are working on building a distributed manufacturing process for spare parts, you should come talk to us because we believe we can help you find a solution for your challenges. We will be at Booth #12.0-D01 at Formnext, come visit us there. You can also learn more about our solution HERE.

What do you think of Velo3D? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: Velo3D