Creating vascular networks to sustain 3D printed organs is becoming possible

The generative design studio Nervous System has collaborated on new 3D printed organ research and has just made the cover of Science Magazine. The studio has always worked at the intersection of science, art and technology. Three fields that have a deep relationship. In fact, they use computer simulation to generate designs from nature that they then produce through digital fabrication. They reveal on their blog that for the past three years they have been working with Jordan Miller, a bioengineer at Rice University on creating vascular networks for 3D printed organs. The work, published in Science Magazine, was led by Jordan Miller at Rice and Kelly Stevens at the University of Washington; it also included collaboration from 13 others.

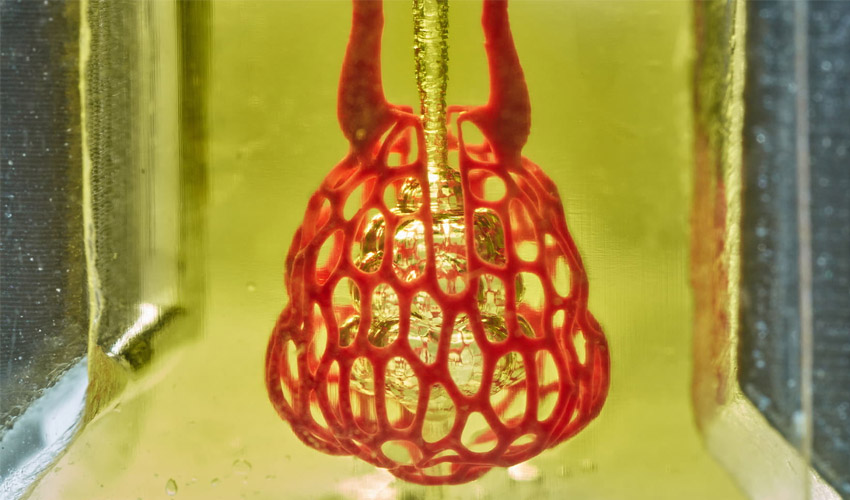

Science, 03 May 2019: Vol. 364, Issue 6439, pp. 458-464 | Credits: Science Magazine

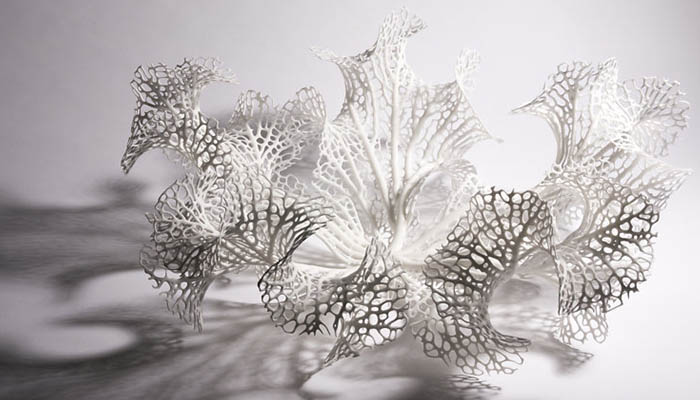

The partnership started in 2016, Jordan Miller was captivated by Nervous System’s ‘growing objects’ exhibit that showcased a series of branching sculptures. The skills needed to create such structures could be applied to a completely different field, Nervous System explains, “He [Jordan Miller] proposed that our skills could be put to an epic task: ‘Perhaps we could work together to make open-source software that the world could use to design synthetic living tissues and organ replacements for human patients’ ”. The idea was born to use the studio’s generative design capabilities to make living things.

The hyphae crispata 1 from the ‘Growing Objects’ exhibition that inspired Jordan Miller | Credits: Nervous System

The design studio explains that while there are many labs creating artificial tissues, the problem is keeping them alive. The issue is feeding the billions of cells that need support from intricate vascular networks. These provide nutrients and oxygen whilst removing waste and without them the artificial tissues soon die. Taking this into account, Nervous System seeks to create software that will enable scientists to design customised multi-vascular structures for 3D printed organs. For the first time, the design studio in collaboration with the Miller Lab successfully designed and created complex multi-vascular networks that were materialised in soft hydrogels.

3D printing vascular networks

The Miller Lab worked to develop bioengineering, 3D printing technology, and cell-culturing techniques to make the designs possible to create. They created the SLATE (Stereolithography Apparatus for Tissue Engineering) 3D printer. This printer is able to inject living cells into soft gels that contain very small and intricate blood vessels. In Nervous System’s blog it reads, “Hydrogels printed in only minutes by SLATE can function as lung-like networks with entangled air/blood networks. This new printing method allows for new and dramatic architectural freedoms in the living tissues we can design and fabricate. Bioengineers don’t have tools at their disposal to generate these complex architectures that are crucially needed to keep living tissues alive”.

Credits: Jordan Miller – Rice University

The software for 3D printing generates “entangled vessel networks within any user-defined volume and connect these networks to inlets and outlets so air and blood can flow through the intertwined networks”. The vessels created are only 300 microns wide. As of now, the tests have only been carried out for small structures – alveolar subunits were printed and tested for example – but much larger networks of them will be tested for efficiency and potential as lung replacements. It is more challenging to feasibly 3D print then to design at this point in time, “It took us three days to generate the lung-mimicking architecture but it too about a year until it was possible to fabricate it.”

Finally, Nervous System writes in their blog, “We feel very lucky to have had the chance to participate in this ground breaking research and are excited to keep working with Jordan Miller and his team on this project going forward.” You can read the full text HERE, the research paper is also available HERE.

What are your thoughts on this new research? Let us know in a comment below or on our Facebook and Twitter pages! And remember to sign up for our free weekly Newsletter, to get all the latest news in 3D printing send straight to your inbox!