Using 3D Printing in the Fight Against Fast Fashion

When it comes to the environmental concerns plaguing our planet, the textile industry is quickly coming under scrutiny as one of the worst offenders. The rapid change in fashion trends, the constantly appearing new collections and the growing consumption of clothing are leading to an enormous amount being produced worldwide. So-called fast fashion ultimately means that huge quantities of textiles end up in the bin every day, and more and more clothing is being produced. To address this, both environmentalists and new governmental directives are calling for the global textile value chain to be made more resource-efficient and sustainable. Now, in order to counteract the vicious circle of throwing away and buying new textiles and to promote local production and the circular economy, a team of researchers at the University of Art and Design Linz has dedicated itself to the problem, using innovative materials and technologies such as 3D printing to make clothing.

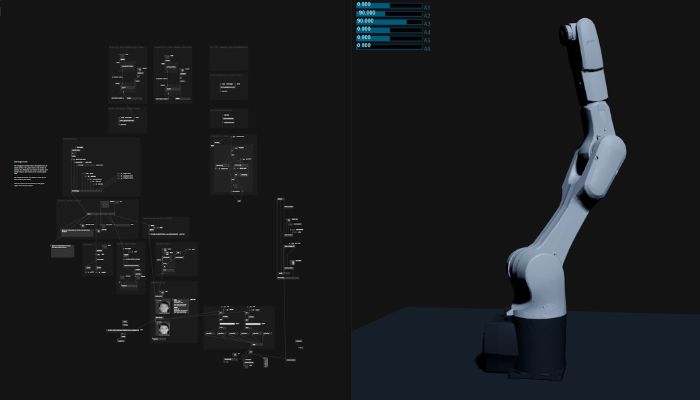

As part of their artistic-scientific PEEK project “Fashion and Robotics,” the researchers are developing new approaches for more sustainable fashion production. The project, which is funded by the Austrian Science Fund (AWF), combines the development of organic fabrics that grow three-dimensionally from a nutrient solution, robots for repairing holes in clothing and AI to streamline factories. The team’s research focused primarily on a fundamentally new approach to the production process using innovative technologies such as 3D printing and new materials, rather than optimizing the traditional process.

Photo Credits: Fashion Robotics

Innovative Clothing Production and Repair With 3D Printing

In the first stage of the research project, the researchers produced an item of clothing with the help of robots that used 3D printing. In addition, the interdisciplinary team developed robotic arms that are capable of three-dimensional cutting or sewing. The next step was to develop electrospinning. This technology was intended to replace conventional “darning” with an innovative, more sustainable process. According to Braumann, in this, a polymer is sprayed onto the torn area of a garment in a high-voltage field by a robotic arm, forming nanofibers that bond with the textile.

This robotics for repairing clothing has promising advantages. Automation can reduce repair costs to around $2, making repairs more affordable than buying new items and therefore more attractive again. Such robots could also be used in high-volume factories and thus contribute to more sustainable production, says Braumann. Furthermore, for factories, an AI would be able to scan the broken clothing in advance and recognize areas that need to be repaired. However, the technology could also be used beyond repair for the “3D redesign” of clothing in alteration shops. This would extend the life cycle of clothing.

Shirts and pants made from bacterial cellulose (photo credits: Fashion and Robotics)

To make fashion materials more sustainable, the researchers have also worked with Werner Baumgartner to grow 3D trousers and 3D shoes for the first time. In the process, newly developed, non-fiber-based biomaterials replace the usual cutting and sewing of textiles. The materials grow from bacteria, and even in three dimensions, for example with the help of shoe lasts, from which the finished shoe can ultimately be detached.

Christiane Luible-Bär, a lecturer at the University of Art and Design Linz who took part in the project, explains, “The robot is also important in this case, but in a new role, namely as a food provider. The bacteria need to be supplied with a nutrient solution regularly at specific times, and a machine can feed them more reliably than a human.”

Although the garments grown from bacterial cellulose are currently only the results of basic research experiments, they represent a step towards the one day realized application of the process. More information can be found HERE on the website of the Austrian Economic Fund.

What do you think of the research project to develop new, innovative repair and manufacturing processes for clothing, including using 3D printing? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: AWF

I own a sustainable fashion brand where I use 3D printing with received filament for accessories and notions! But I would like to have access to more equipment to recycle plastics even more.

I found the fixing holes robot interesting, things like this could be a big leap forward for the sustainable fashion movement.