US, Germany Invested Millions in Subsea Energy Storage Utilizing 3D Printing

At a time when climate change is becoming an increasing threat to our planet, it is critical to start adopting sustainable energy sources and technologies. The project Stored Energy in the Sea (StEnSea) was developed in 2012 for that reason. Conceived by the German Fraunhofer Institute and supported by Sperra and PLEUGER, the project aims to revolutionize long-duration energy storage by adapting the principles of pumped storage hydropower for subsea environments. Notably, the technology leverages 3D printing.

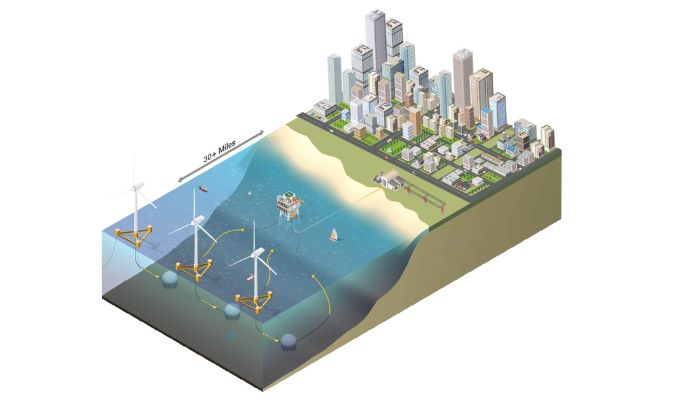

The project enables a unique approach to energy storage by putting hollow, 3D printed concrete spheres on the seabed at depths of 600 to 800 meters. These spheres are adaptable. When the electricity demand is low, the spheres are emptied of water using PLEUGER’s submersible pumps to store potential energy. When the electricity demand is at its peak, water can flow back into the spheres, turning the pumps into turbines that generate electricity.

Image credits: Sperra.com

The method has an effect similar to traditional pumped storage hydropower but is adapted for the subsea environment. The system takes advantage of ocean pressure to store and release energy efficiently. Additionally, the solution addresses the demand for scalable, efficient energy storage that is compatible with renewable energy sources, reducing reliance on fossil fuels and stabilizing power grids.

According to a GIS analysis of coastal marine areas, there are multiple potential locations for deploying this technology. Some options include off the coasts of Norway, Portugal, the US East and West Coasts, Brazil and Japan. Deep natural or artificial lakes could also host this technology, which further expands its potential.

International Investments in Subsea Energy Storage

The United States and German governments offered significant financial support for the project. The U.S. Department of Energy Water Power Technologies Office (WPTO) has awarded the project $4 million, and the German Ministry for Economic Affairs and Climate Action (BMWK) committed €3.7 million. Their international collaboration is a testament to the project’s potential global impact.

Anton Schneerson, CEO of Pleuger Industries explained the StEnSea project’s importance. “The global energy transition demands transformative, scalable solutions, and Pleuger is leading the way. Our ‘Stored Energy in the Sea’ project aligns with our strategy to expand in renewables, advancing ocean-based technology that redefines sustainable energy.”

When StEnSea came to be in 2012, PLEUGER specially designed an underwater pump to help with the prototype. The project will now include a 10-meter prototype capable of generating 0.5 MW of power at depths exceeding 600 meters, thanks to the new funding and international partnerships.

How Does Subsea Energy Storage Work?

What’s special about these pumps is that they are designed to operate under extreme pressures and in harsh environments, while still being a reliable source of energy generation and storage.

“Pumped storage power plants are particularly suitable for storing electricity for several hours to a few days,” Dr. Bernhard Ernst, Senior Project Manager at Fraunhofer IEE said. “However, their expansion potential is severely limited worldwide. Therefore, we are transferring their functional principle to the seabed – the natural and ecological restrictions are far lower there. In addition, the acceptance of the citizens is likely to be significantly higher.”

By creating energy storage underwater, engineers can avoid many challenges associated with working on land, such as environmental impact and land use conflicts. Additionally, this solution offers an alternative to using critical materials that could otherwise be used for battery storage. The sustainable solution is estimated to be able to offer 7.5 terawatts and 75 terawatt-hours of net technical potential in U.S. waters alone.

Sperra, headquarter in Colorado, is dedicated to creating renewable energy solutions through automated construction. The company is developing 3D printed concrete products, like the 3D printed spheres, to help achieve their mission. Sperra can have lower manufacturing costs because of their use of 3D printing. Conventional concrete construction is labor intensive, with steps like formwork assembly, casting, and formwork removal, but with the company’s automated 3D printing, it can complete the work faster while maintaining high quality. Learn more about the StEnSea project here.

What do you think of the potential of subsea energy storage? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.