The US Army invests up to $11 million in the development of new polymers

The US Army keeps exploring the wide range of possibilities provided by additive manufacturing technologies. Recently, the Army allocated $11 million in total for the research and development of new high-performance polymer materials. Who will be conducting the research? The five-year contract was awarded to Case Western Reserve University and PolymerPlus, and two other sub-contractors. For the moment $5,4 million were granted to the involved teams by the US Army Research Laboratory (ARL), but potentially, the amount can rise up to $11 million. Why is the Army interested in the development of high-performance polymers? Because the optimized materials can be potentially used for the production of weapons, protective helmets and other types of equipment.

Case Western Reserve University stands out among other educational institutions as it is home to the nation’s first stand-alone polymer department as well as the first one to offer a Bachelor of Science program in polymer science. As for PolymerPlus, it is a polymeric technology company that provides services and fabrication of custom nano-layered polymer products to government and corporate clients. The teams from these two organizations will cooperate with the Army Research Laboratory in Aberdeen Proving Ground, Maryland, to design materials and advanced manufacturing approaches for high-performance composites.

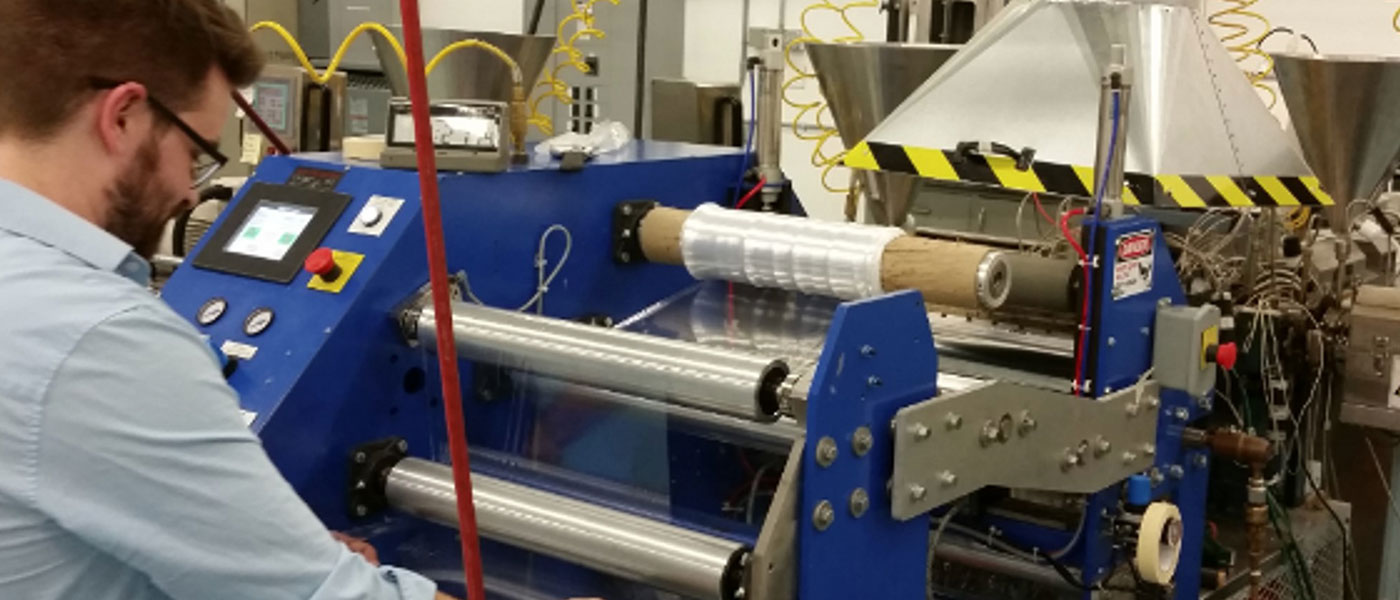

For the Army funded project, the team at Case Western will experiment with new combinations of ultra-thin plastics and send them to PolymerPlus for larger-scale processing. The novel 3D printing technique includes the usage of multilayer co-extrusion, which is a polymer processing technology that produces high-strength fiber films with thousands of micro-scale layers. This leads to the formation of new materials that are significantly stronger and more durable, but also remarkably lightweight.

The President of PolymerPlus, Mike Ponting, explained “What we’re looking to do is use our process to combine low- to mid-cost plastics—things like milk jugs and trash bags at a cost of about $3 a pound—to create a strong, flexible material equal to things like Super Kevlar, which are about $100 a pound. The Army has seen some of the initial samples and technology, but now they want to see how far we can take this.”

Meanwhile, Joseph Lenhart, chief of the Polymers Branch at the Army Lab commented, “Case Western Reserve University and PolymerPlus can continuously manufacture complex combinations of materials into unique structures that are difficult to generate even with sophisticated laboratory techniques. We see tremendous opportunities for improving the performance of protective systems and weapons. Longer term, we are excited about the applications we have not even imagined.”

Nanolayer film coextrusion technology for polymers. (Image credits: Case Western Reserve University)

What do you think about US Army sponsoring the development of a new polymer making technology? Let us know in a comment below or on our Facebook and Twitter pages! Sign up for our free weekly Newsletter, all the latest news in 3D printing straight to your inbox!